Heat pipe structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

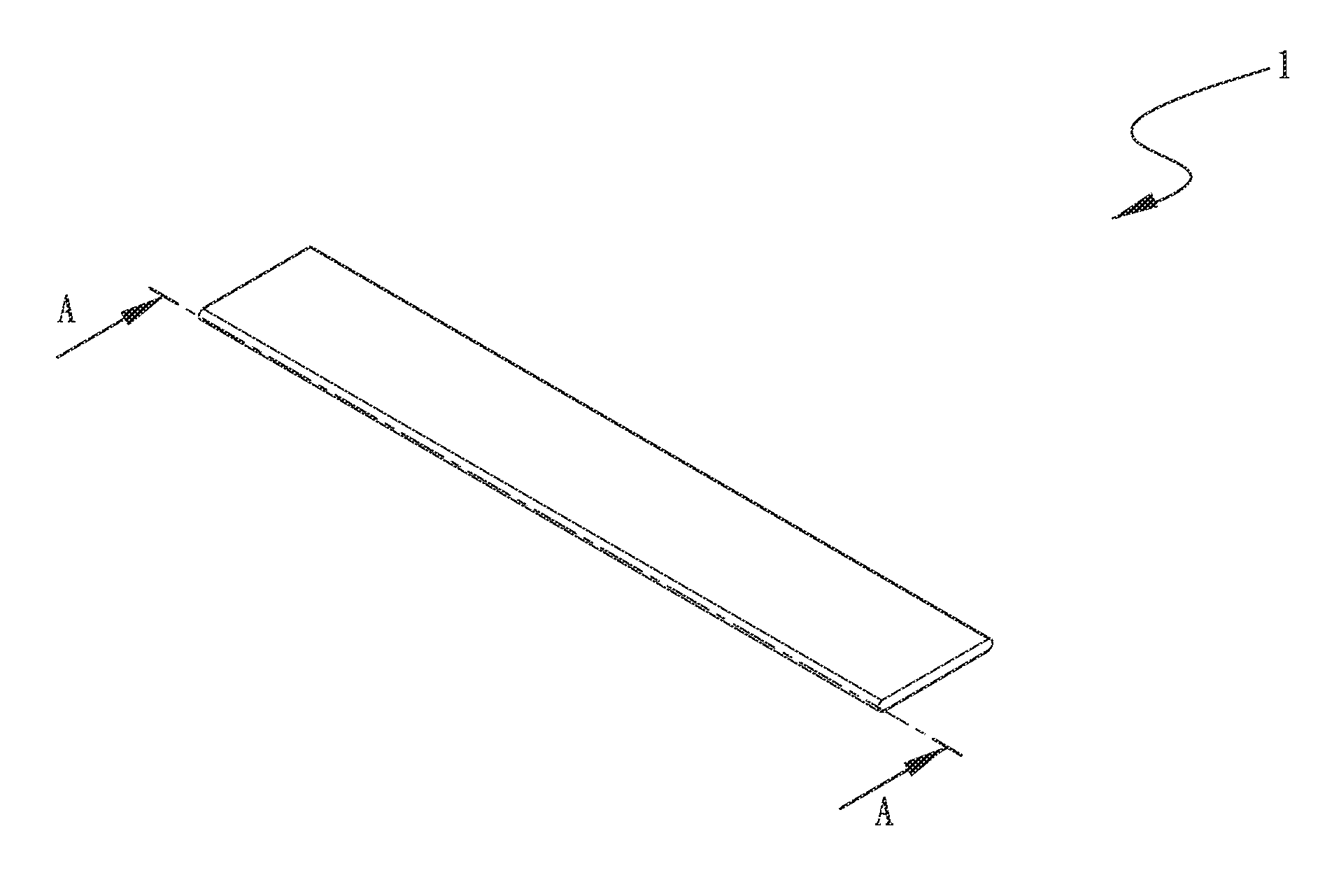

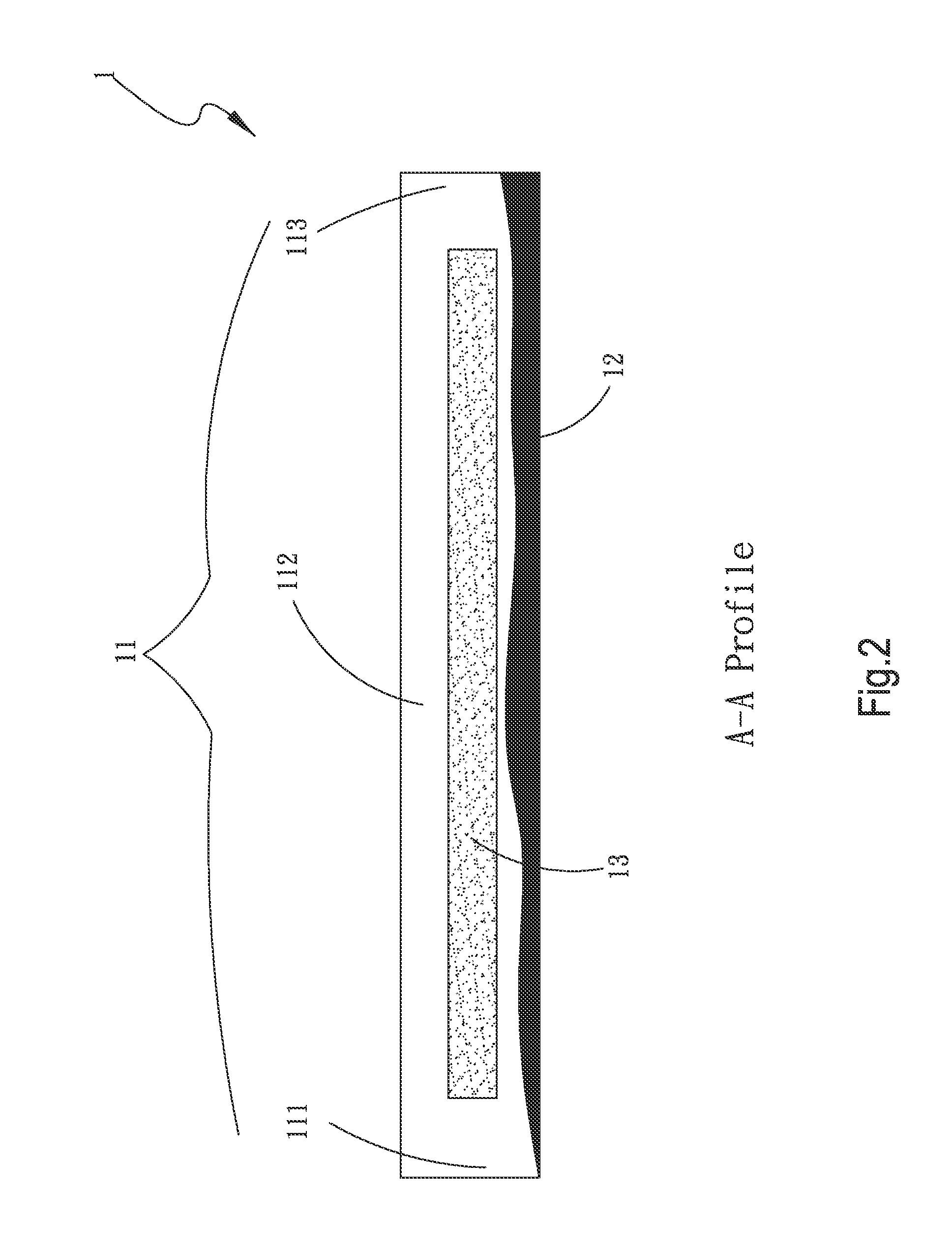

[0026]Please refer to FIGS. 1 and 2. FIG. 1 is a perspective view of a first embodiment of the heat pipe structure of the present invention. FIG. 2 is a sectional view of the first embodiment of the heat pipe structure of the present invention, taken along line A-A of FIG. 1. According to the first embodiment, the heat pipe structure of the present invention includes a tubular body 1.

[0027]The tubular body 1 has a chamber 11, a working fluid 12 and a first capillary structure 13. The chamber 11 is defined with at least one first section 111, a second section 112 and a third section 113. The first, second and third sections 111, 112, 113 are connected with each other. The first capillary structure 13 is disposed in the second section 112. The chamber 11 has a smooth inner wall.

[0028]The first capillary structure 13 is selected from a group consisting of sintered powder body, mesh body, fiber body and porous structure body. In this embodiment, the first capillary structure is, but not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com