Cooling device and method therefore for co2 washing machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

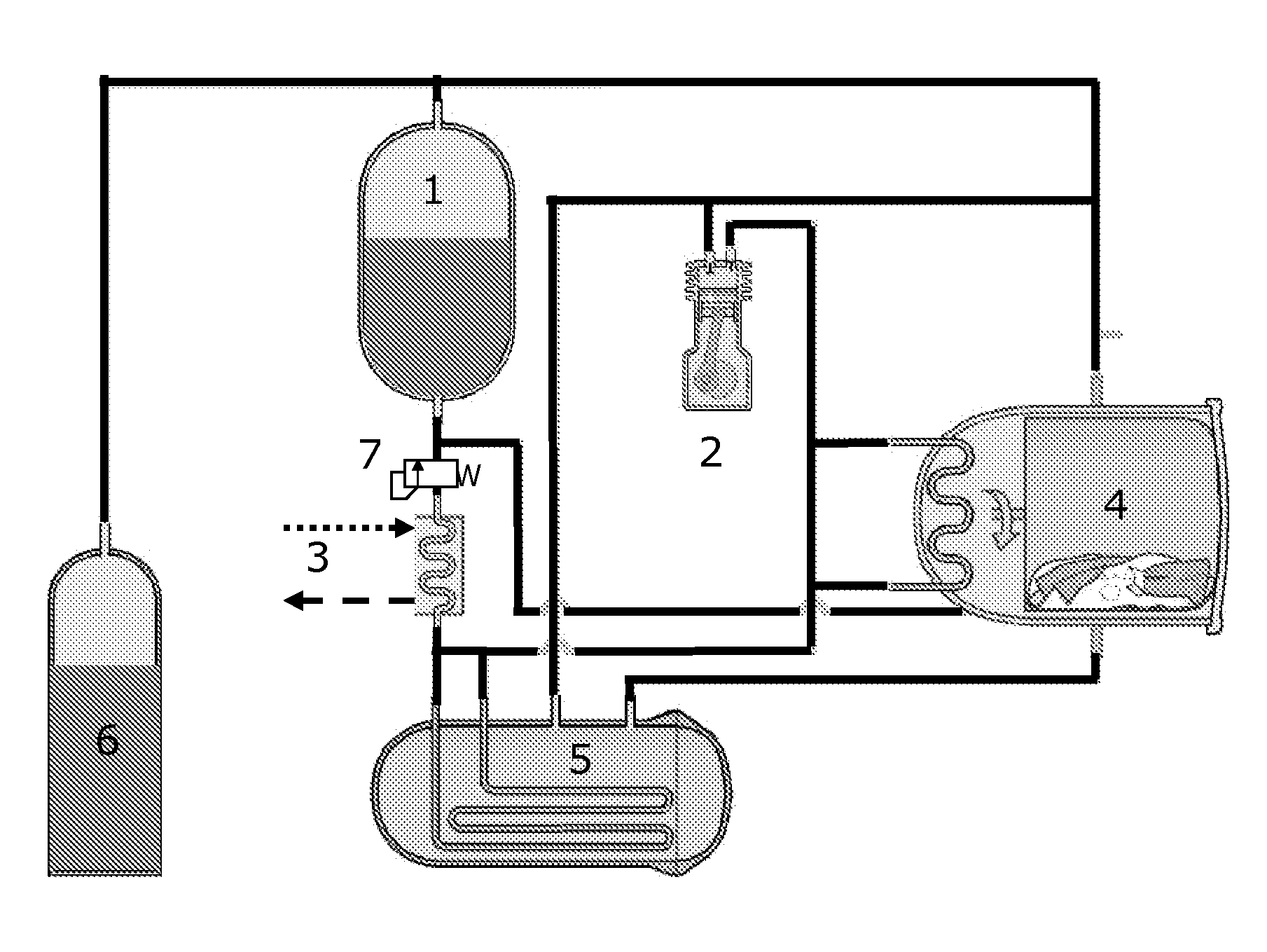

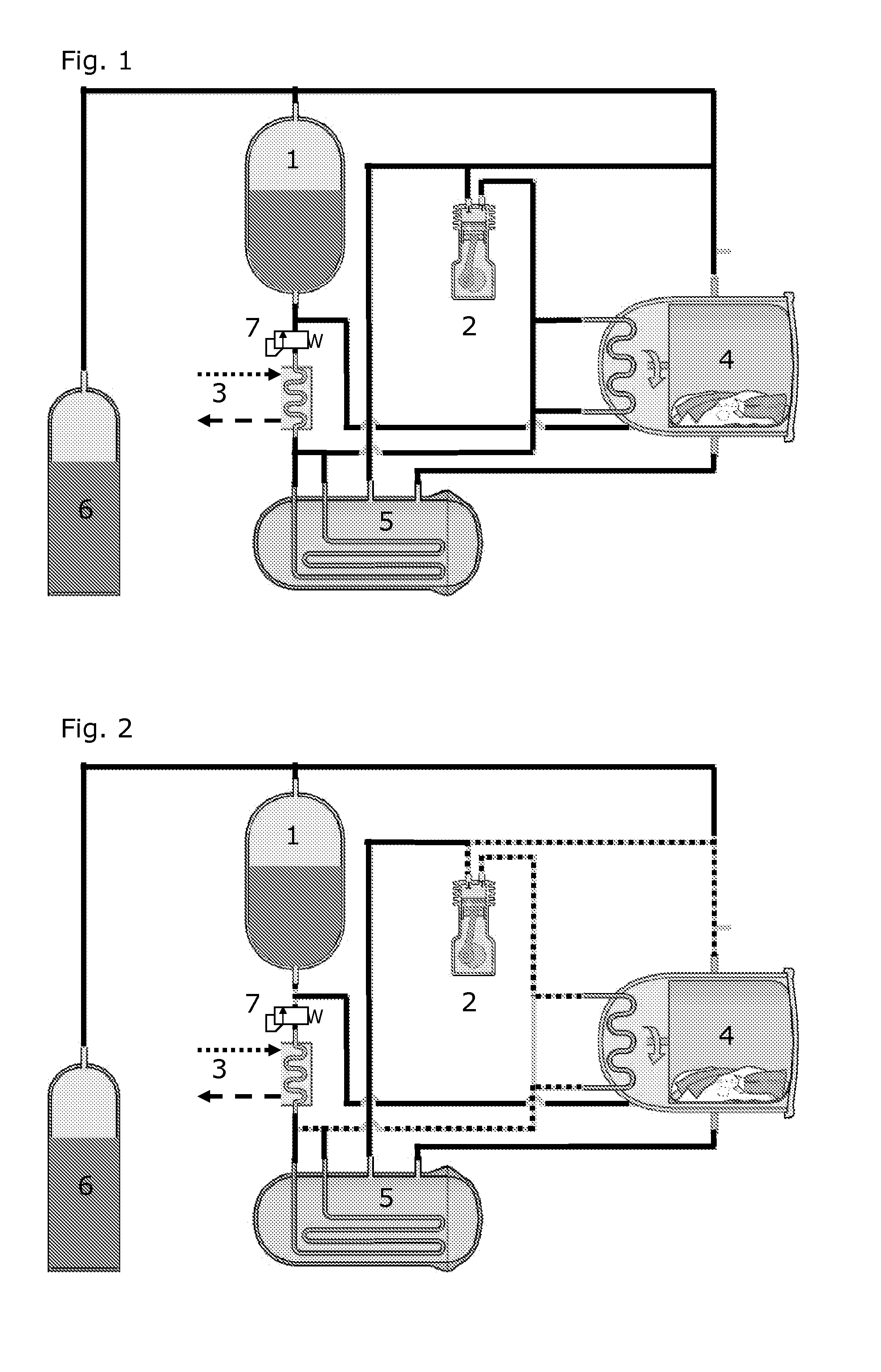

[0024]FIG. 1 shows a dry cleaning apparatus according to the present invention comprising a storage device 1, a compressor 2, a cooling unit 3, a cleaning chamber 4 for cleaning fabrics, a distiller 5, a refill tube 6 and a regulator 7. The dry cleaning apparatus preferably uses carbon dioxide as solvent fluid which is stored in the storage device 1.

[0025]When a cleaning program is started the fluid is transferred via pipes to the cleaning chamber 4 in order to clean the articles that are present in the cleaning chamber 4. In order to have the fluid in the right phase where the cleaning effect is as effective as possible the compressor unit 2 builds up a pressure in the apparatus.

[0026]However the compressor unit 2 does not necessarily directly influence what phase the fluid is in, within the cleaning chamber 4, during e.g. a cleaning process. This is dependent on the temperature and / or pressure in accordance with the ideal gas law or related laws. For example the temperature can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com