Electric arc furnace

A technology of electric arc furnace and refractory lining, which is applied in the field of electric arc furnace, can solve the problems of difficulty in installation and maintenance of refractory lining, reduction of lining structural strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

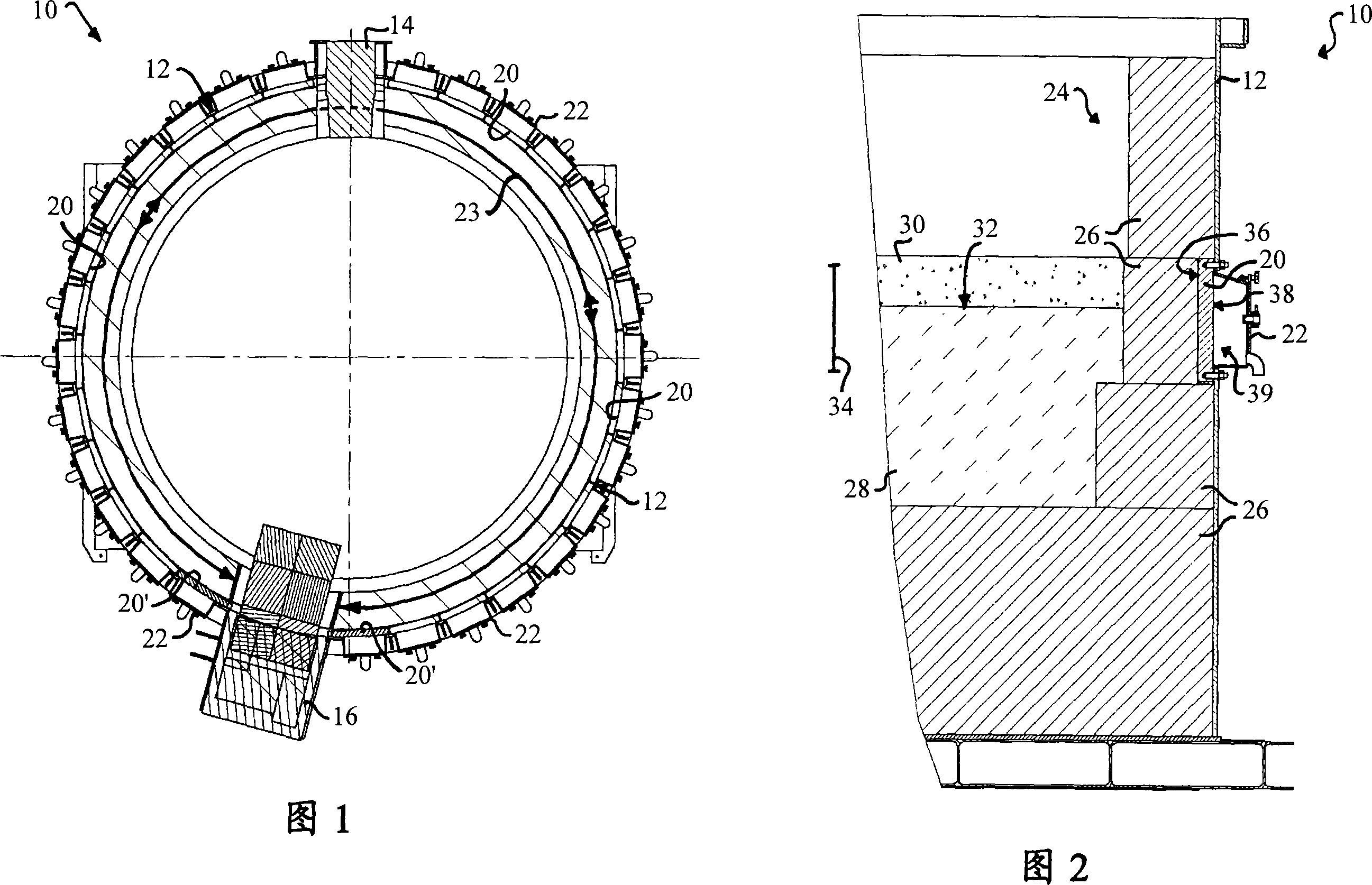

[0027] FIG. 1 shows a horizontal section through an electric arc furnace, which is generally indicated by the reference numeral 10 . The cylindrical outer furnace shell 12, made of welded steel plates, is internally lined with refractory material. The section in Figure 1 is through a taphole 14 for discharging molten metal and also shows a slag door 16 for discharging slag formed on top of the pool of molten metal during operation.

[0028] As shown in FIG. 1 , a plurality of copper slabs (copper slabs) 20 , 20 ′ are installed inside the housing 12 . Each copper plate 20, 20' is provided with a cooling box 22. The copper plates 20, 20' are mounted adjacently so as to form a substantially continuous inner cooling ring, indicated by circular arrows 23. During operation of the electric arc furnace 10, the inner cooling ring 23 uniformly cools a specific area of the refractory lining (not shown in FIG. 1 ). It can be noted that the inner cooling ring 23 is interrupted by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com