Tents and support frames for tents

a technology for supporting frames and tents, which is applied in the direction of tents/canopies, buildings, constructions, etc., can solve the problems of increasing the erection/striking time of tent frames, cumbersome collapse or erecting of frames, and time and often knowledge/skills they need to erect correctly, so as to reduce friction and reduce the amount of effort. , the effect of reducing the wear of rop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

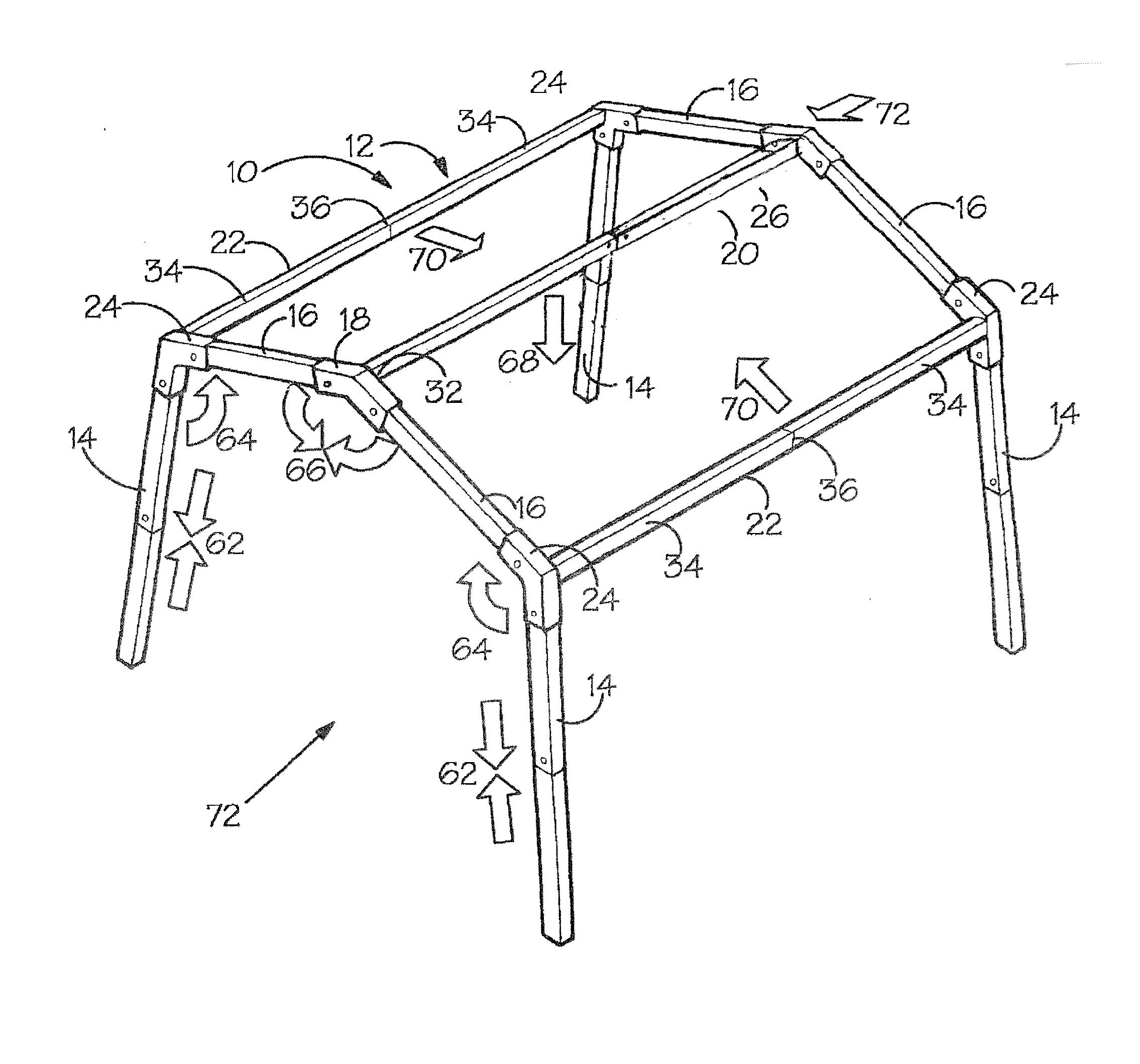

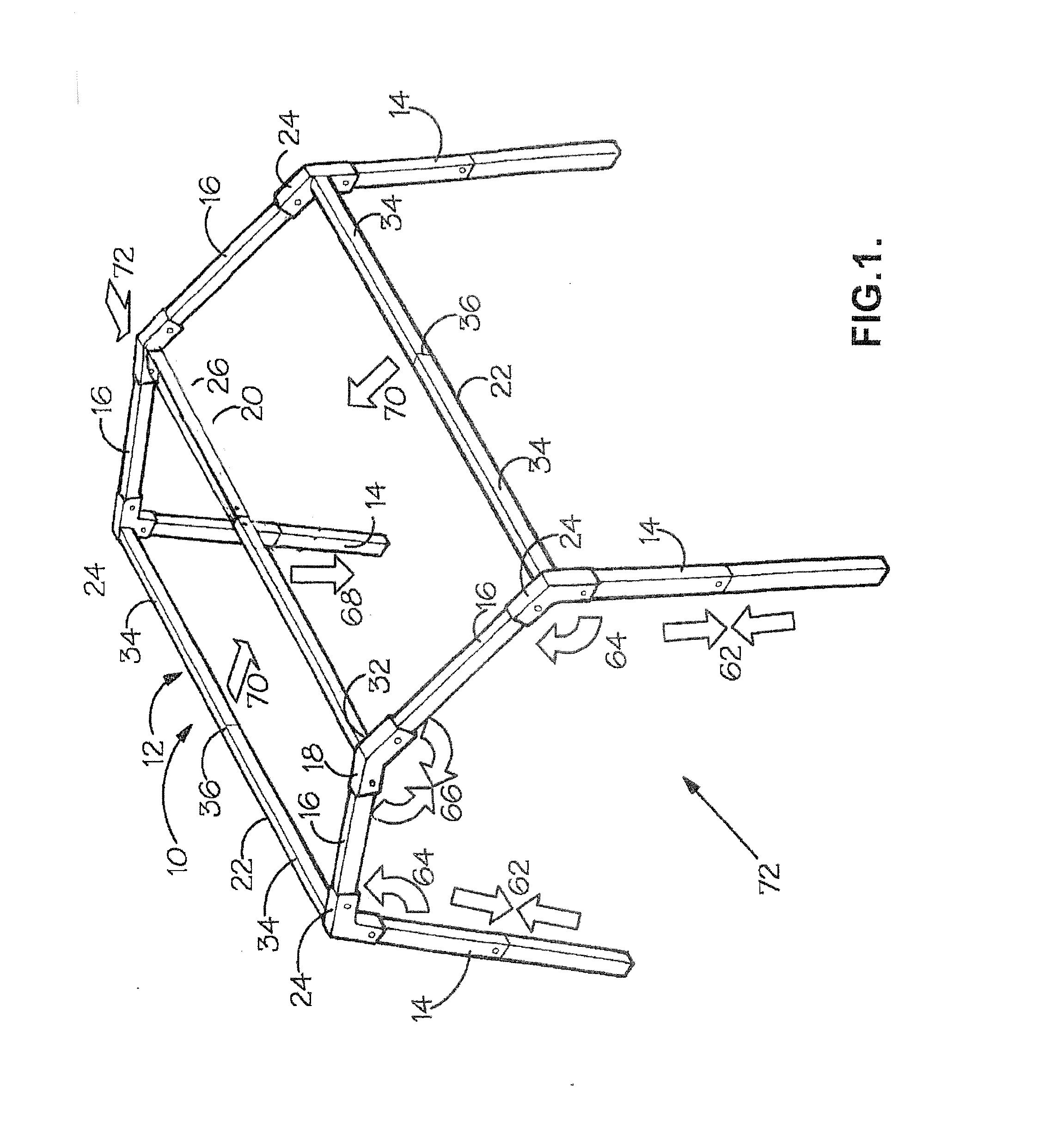

[0039]In FIG. 1, a support frame 10 for a tent comprises a roof 12 supported off the ground by four splayed legs 14. The roof 12 and legs 14 are manufactured from various lengths of generally rectangular-section aluminium tubing which are connected to one another at their ends using hinges or connectors, which shall be described in detail below.

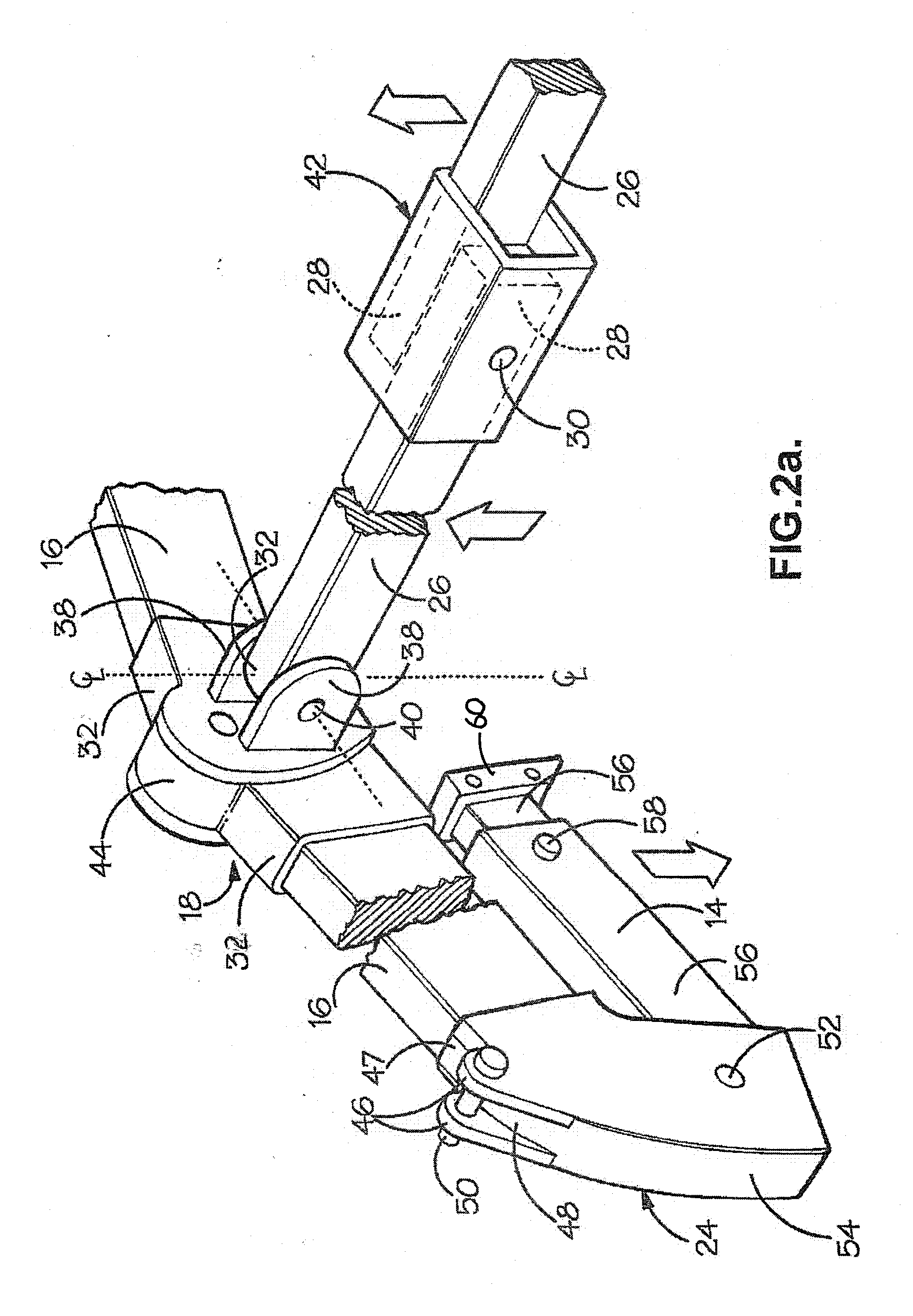

[0040]The roof 12 comprises a pair of spaced-apart and parallel gables each gable comprising a pair of inclined rafters 16 which are hingedly connected to one another at their upper ends by an apex connector 18. The apex connector 18 and rafters 16 all lie substantially in a common piano, or parallel planes, hereinafter the plane of the gable. The gables are connected to one another by: a ridge beam 20, which extends perpendicularly outwardly from, and which spans the distance between the apex connectors 18; and by a pair of parallel eaves beams 22 which extend perpendicularly outwardly from, and which span the distance between two leg connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com