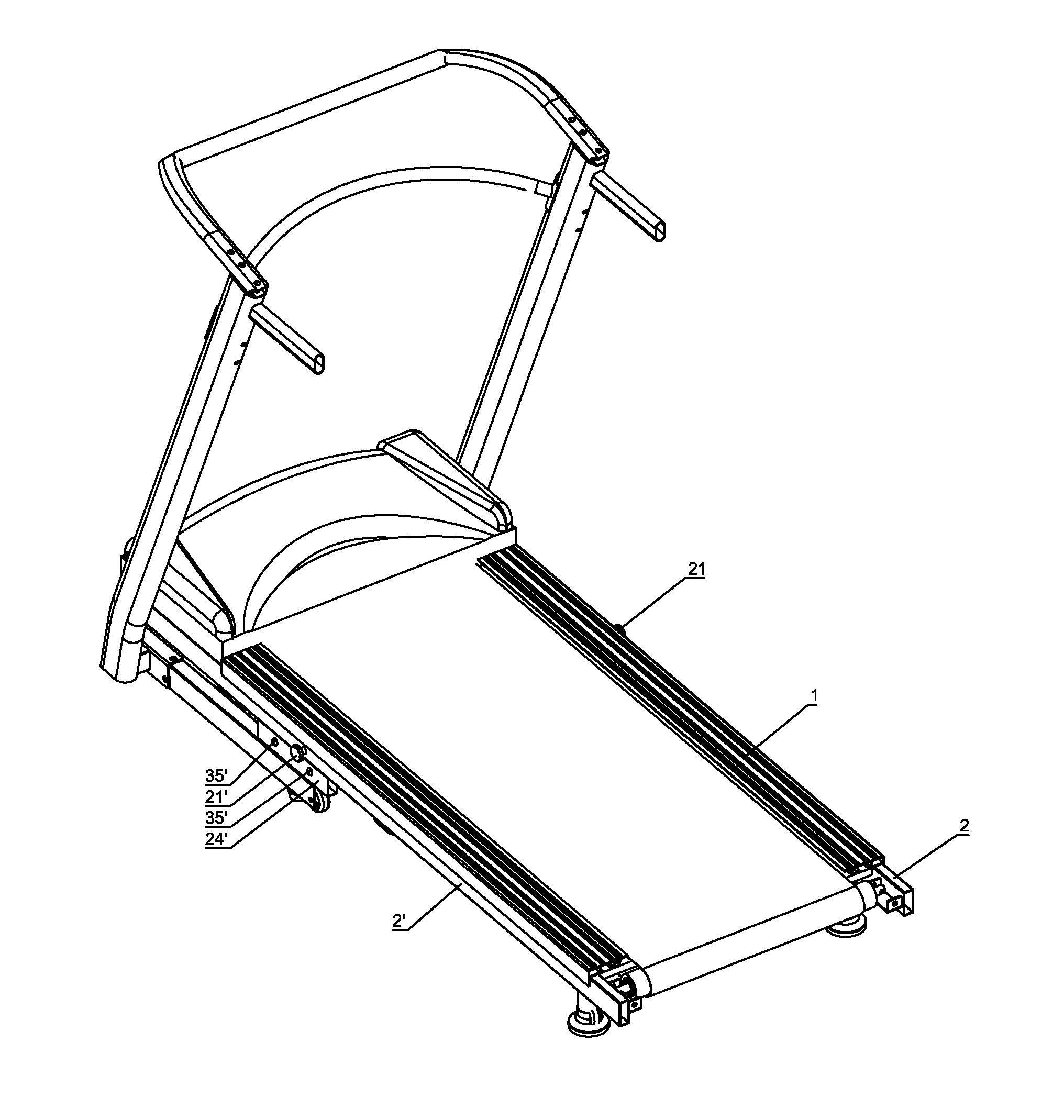

Buffer structure of treadmill

a buffer structure and treadmill technology, applied in the field of buffer structure of treadmills, can solve the problems of troublesome operation, affecting the stability of the treadmill, and affecting the smoothness of the slide, so as to achieve the effect of simple adjustment and reduce the limitation of arrangemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

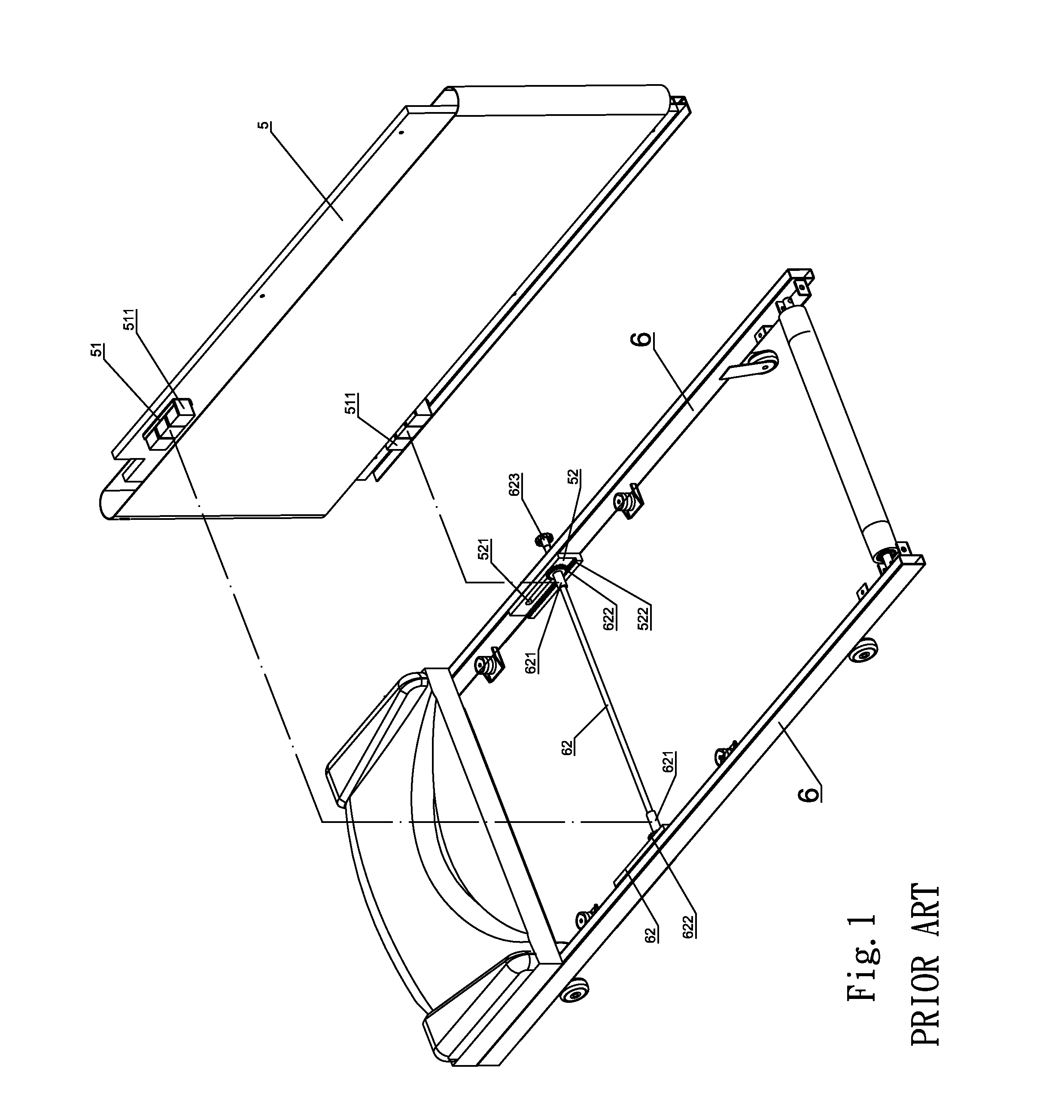

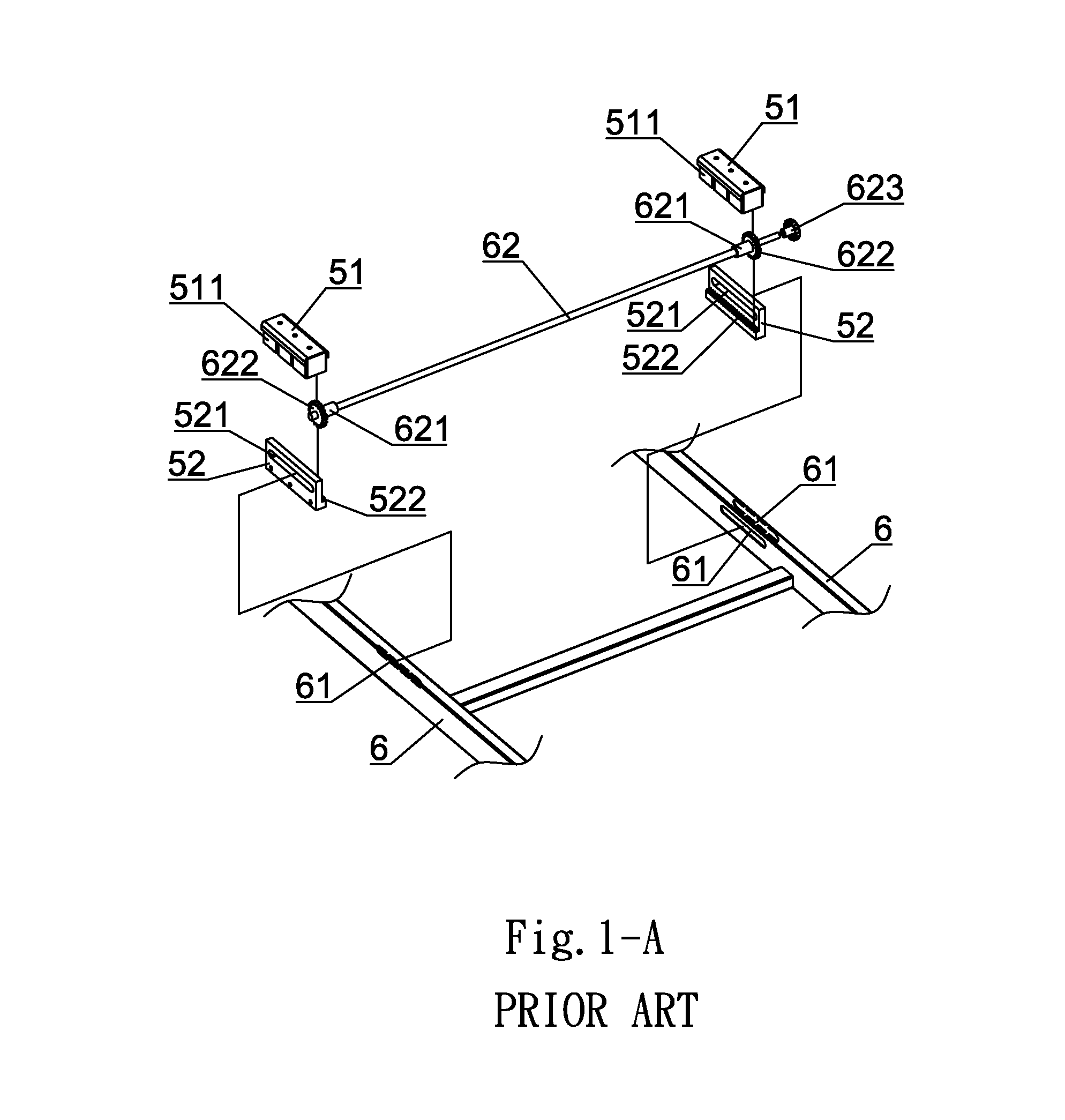

[0029]FIG. 2 through FIG. 5 and FIG. 3-A show the present invention. The link rod 23 to connect the hand wheels 21, 21′ and the gear wheels 22, 22′ penetrates the central sections of the two side rods 2, 2′. The two tooth racks 3, 3′ are coupled to the inner sides of the fixing rods 24, 24′ through the slide bolts 35, 35′, with the toothed portions 31, 31′ to mesh with the gear wheel 22, 22′. The buffer members 111, 111′ lean against the upper ends of the hollow cylinders 34, 34′. When the user wants to adjust the buffer degree, he / she can still stand on the load board 1 and turn either of the hand wheels 21, 21′ by himself or another person. The link rod 23 and the two gear wheels 22, 22′ are driven together to mesh with the two tooth portions 31, 31 so that the two tooth racks 3, 3 are slid through the two slots 34, 34′. Through the sleeves 353, 353′ on the slide bolts 35, 35′, the tooth racks 3, 3′ can be slid smoothly. After adjustment, the hollow cylinders 34, 34′ are moved to ...

third embodiment

[0031]FIG. 8 and FIG. 9 show the present invention. The present invention further comprises a motor 4 located at one end of the buffer unit 11, 11′ under either side of the load board 1 close to the gear wheel 22, 22′ of the corresponding side rod 2, 2′. The motor 4 comprises a transmission gear wheel 41 to mesh with the gear wheels 22, 22′. When the motor 4 is driven, the transmission gear wheel 41 will mesh with the gear wheel 22 at one side to move the tooth rack 3. Through the link rods 23, 36, the gear wheel 22′ and the tooth rack 3′ are linked to activate for adjusting the two hollow cylinders 33, 33′ to be under the desired buffer members 111, 111′, providing an electric adjustment and control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com