Knitted fabric with different pile lengths, knit product and socks using the same

a technology of knitted fabric and pile length, applied in the field of knitted fabric, can solve the problems of insufficient low-pile stitching and wet feelings, and achieve the effect of easing the stretch feeling at the gore lin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

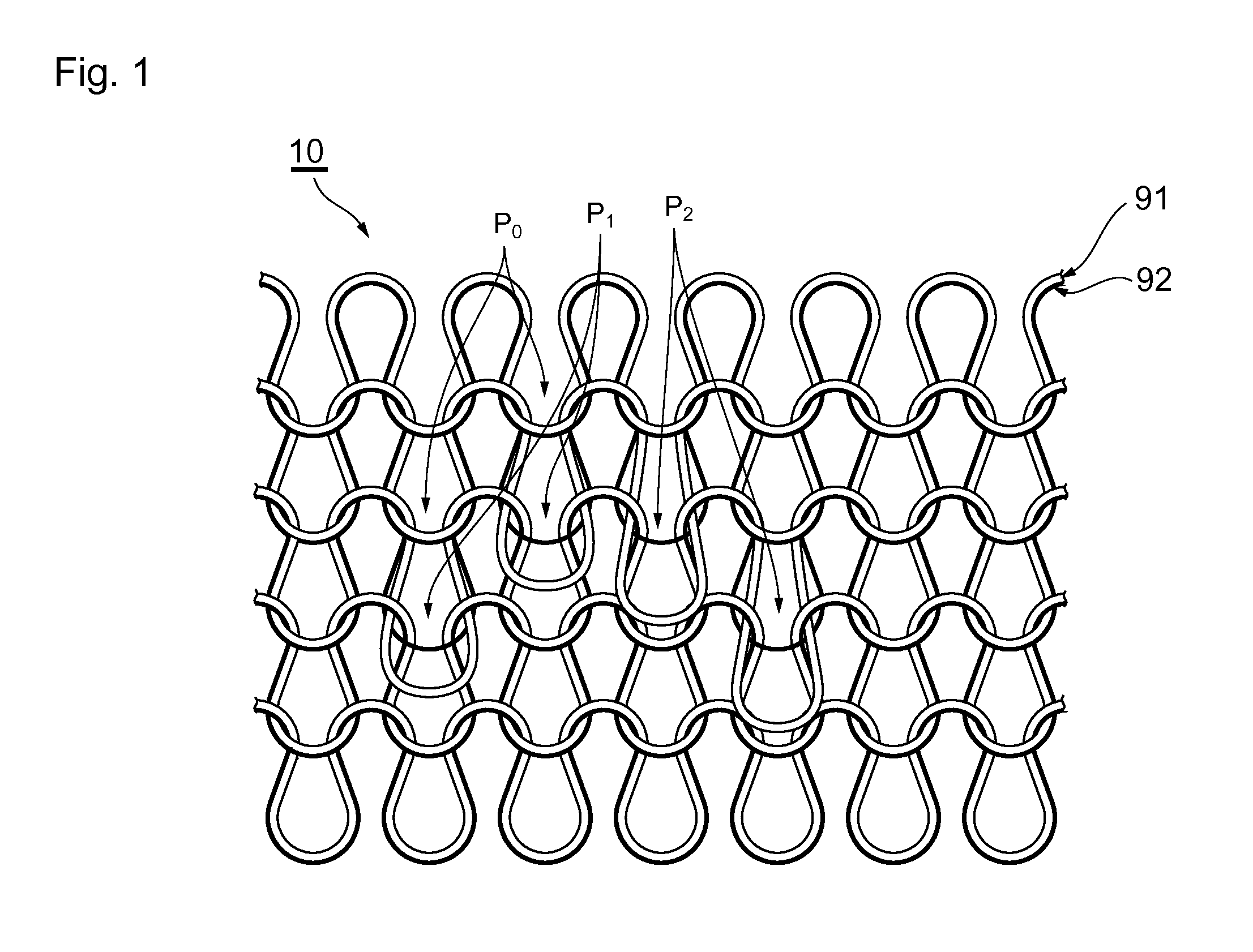

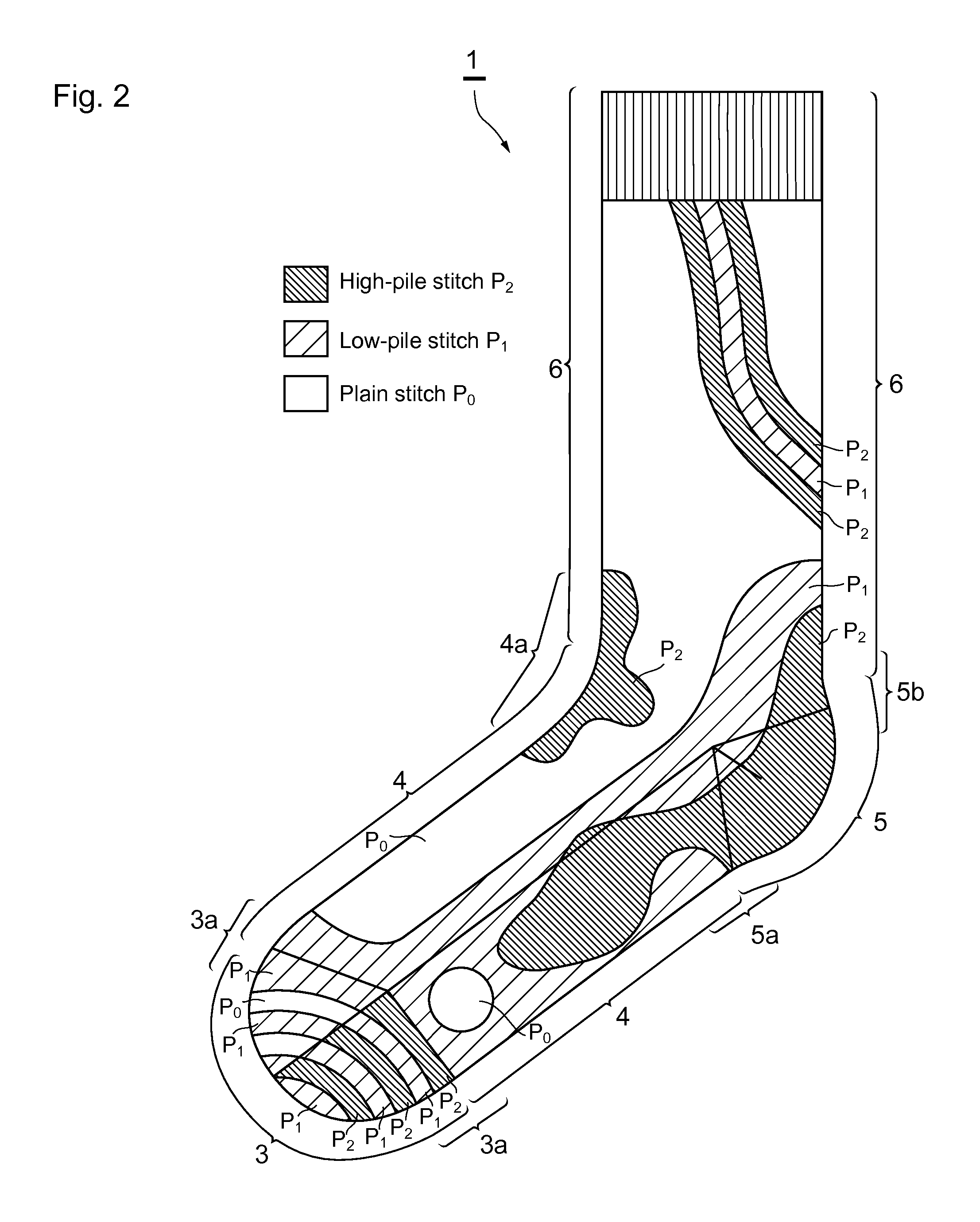

first preferred embodiment

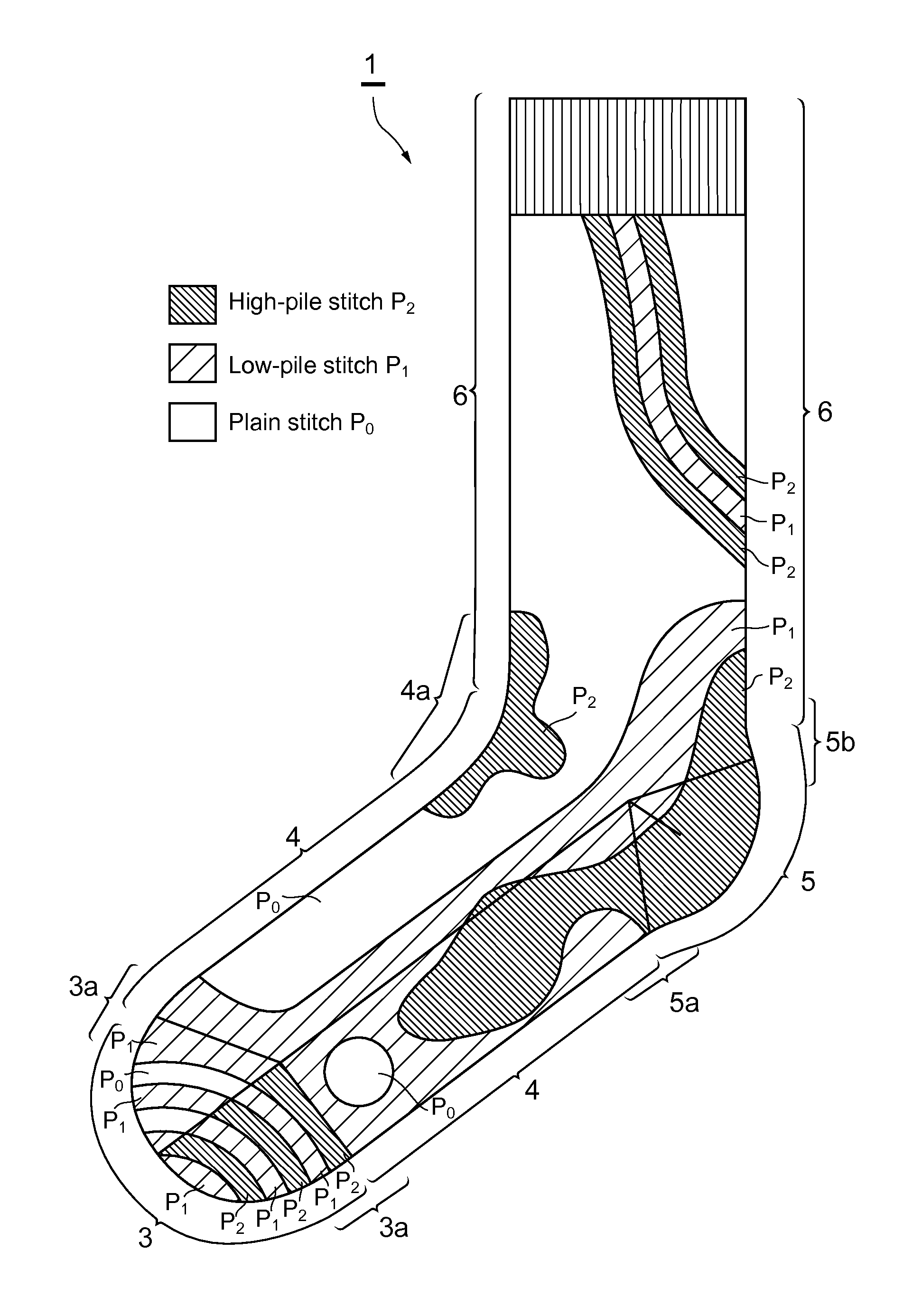

[0039]FIG. 1 is an enlarged view of a portion of a multi-pile knitted fabric (in which a pile length is varied) according to the first preferred embodiment of the present invention and shows stitches therein. The portion shown in FIG. 1 includes a plain stitch (first knitting structure) P0 in which both pile yarn 91 and ground yarn 92 are knitted together and a sinker-loop length of the pile yarn 91 is the same as that of the ground yarn 92; a low-pile stitch (second knitting structure) P1 in which the sinker-loop length of the pile yarn 91 is longer than that of the ground yarn 92; and a high-pile stitch (third knitting structure) P2 in which the sinker-loop length of the pile yarn 91 is longer than that in the low-pile stitch P1. The low-pile stitch P1 is also referred to as a short-pile stitch and the high-pile stitch P2 is also referred to as a long-pile stitch.

[0040]The multi-pile knitted fabric 10 can include a pile motif formed by selectively arranging the low-pile stitch P1 ...

second preferred embodiment

[0060]A sock (knit product) 1A according to the second preferred embodiment of the present invention will now be described. FIG. 6 is a developed view of a toe portion of the sock 1A according to the second preferred embodiment. The legend symbols refer to types of knitting structures. Referring to FIG. 6, a region 51 corresponds to a sole-side portion when this sock is worn, a region 52 corresponds to an instep-side portion when this sock is worn, and a boundary 53 between the regions 51 and 52 corresponds to a toe portion when this sock is worn.

[0061]The sock 1A includes the multi-pile knitted fabric (knitted fabric with different pile lengths) 10 described in the first preferred embodiment in which a pile motif is formed preferably by selectively arranging in the same course a low-pile stitch (second knitting structure) P1 and the high-pile stitch (third knitting structure) P2 on a stitch-by-stitch basis in a region of plain stitches (first knitting structure) P0, or by selective...

third preferred embodiment

[0064]A sock (knit product) 1B according to the third preferred embodiment of the present invention is now described. FIG. 7 is a developed view of a toe portion of the sock according to the third preferred embodiment of the present invention. In FIG. 7, the legend symbols refer to types of knitting structures. As in the example of FIG. 6, the region 51 corresponds to a portion adjacent to a foot-sole of a person when the person wears the sock, the region 52 corresponds to a portion adjacent to an insole, and the boundary 53 between the regions 51 and 52 corresponds to a portion adjacent to a toe.

[0065]The sock 1B includes the aforementioned multi-pile knitted fabric (knitted fabric with different pile lengths) 10 as in the second preferred embodiment. A pile motif is formed in a reciprocating-rotation portion knitted preferably by reciprocating rotation of a cylinder of a circular knitting machine and in a portion extending across the reciprocating-rotation portion and a forward-ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com