Engine cooling fan

a technology for cooling fans and engines, applied in the direction of engine cooling apparatus, liquid fuel engines, mechanical apparatus, etc., can solve the problem of increased blade deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

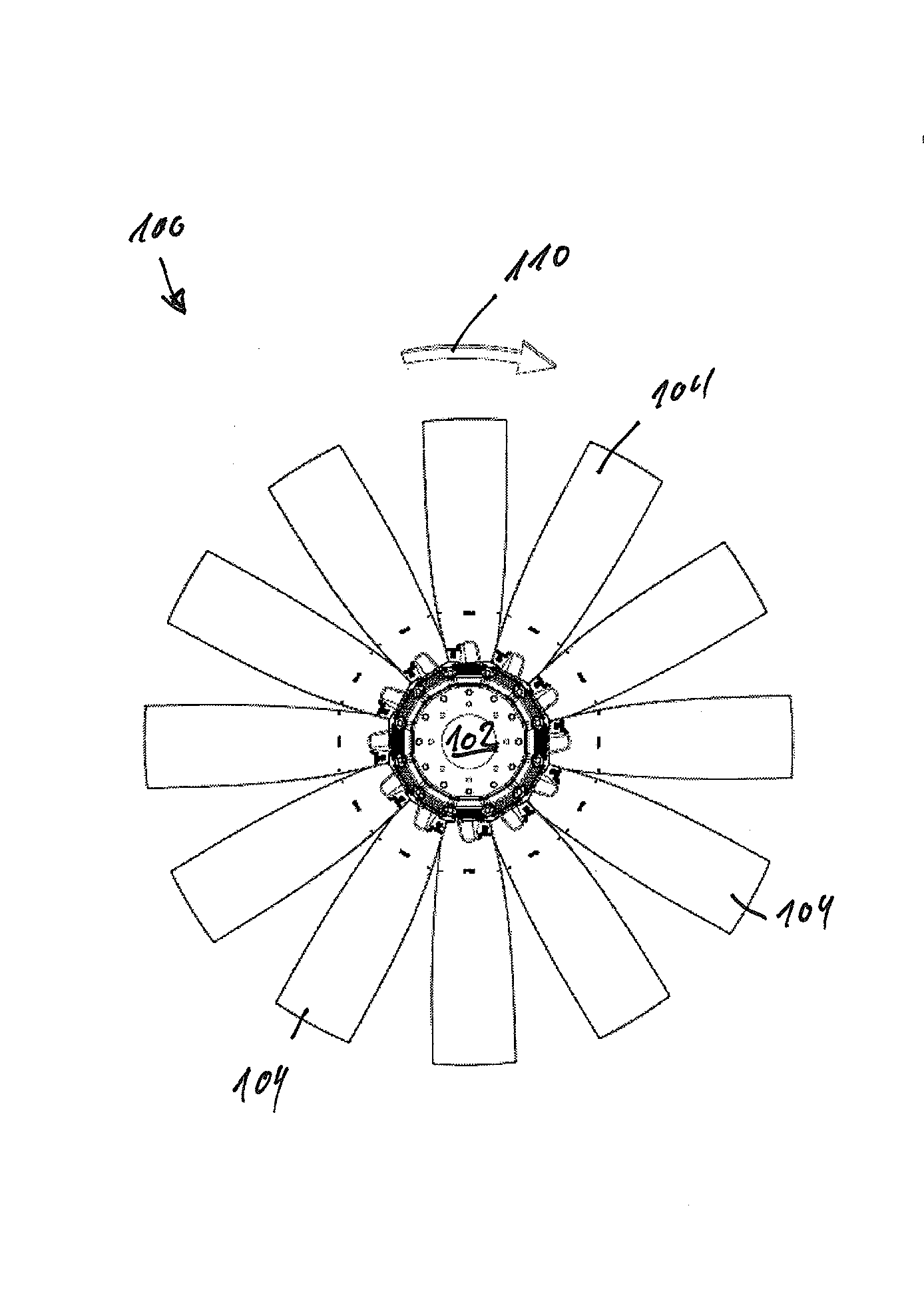

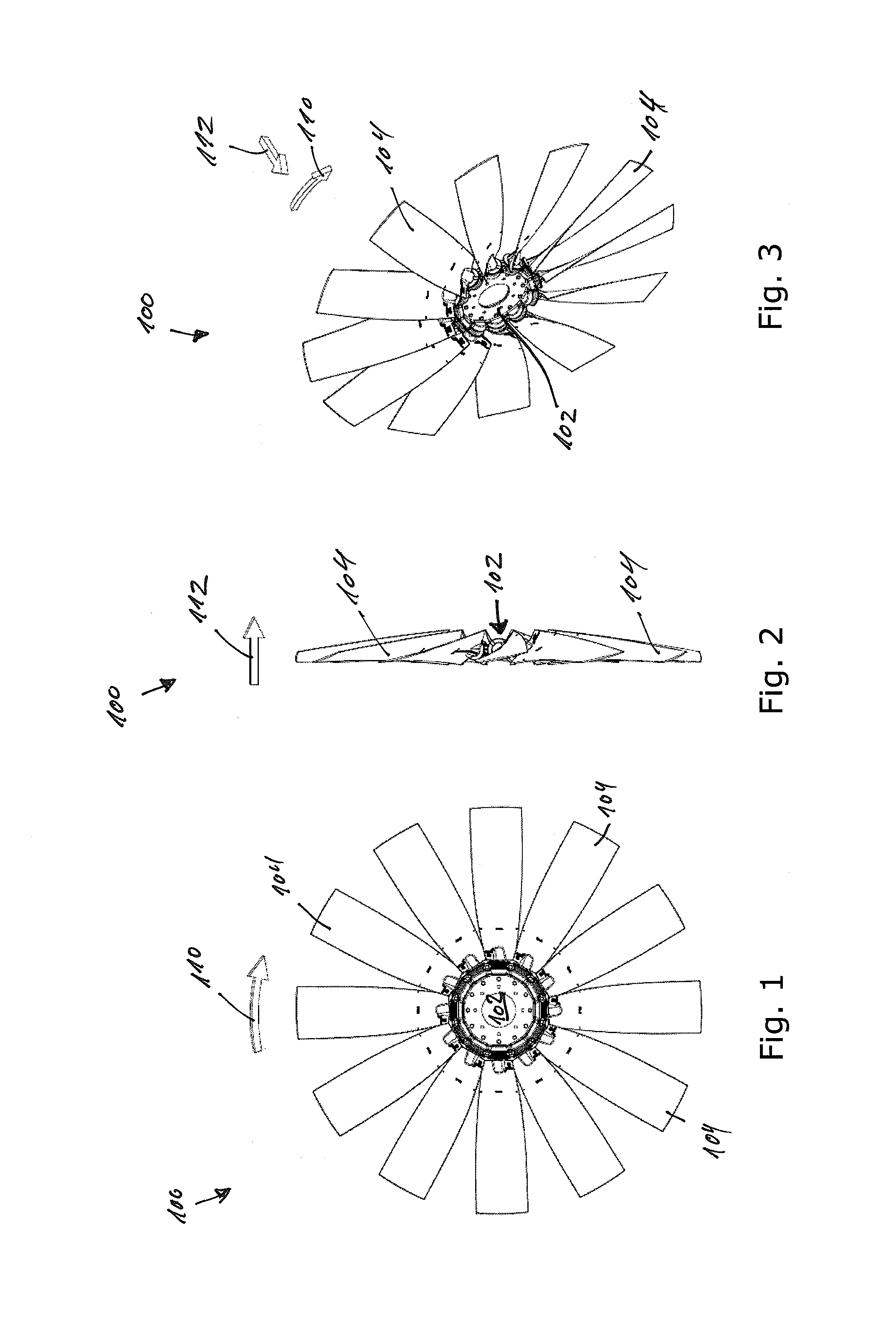

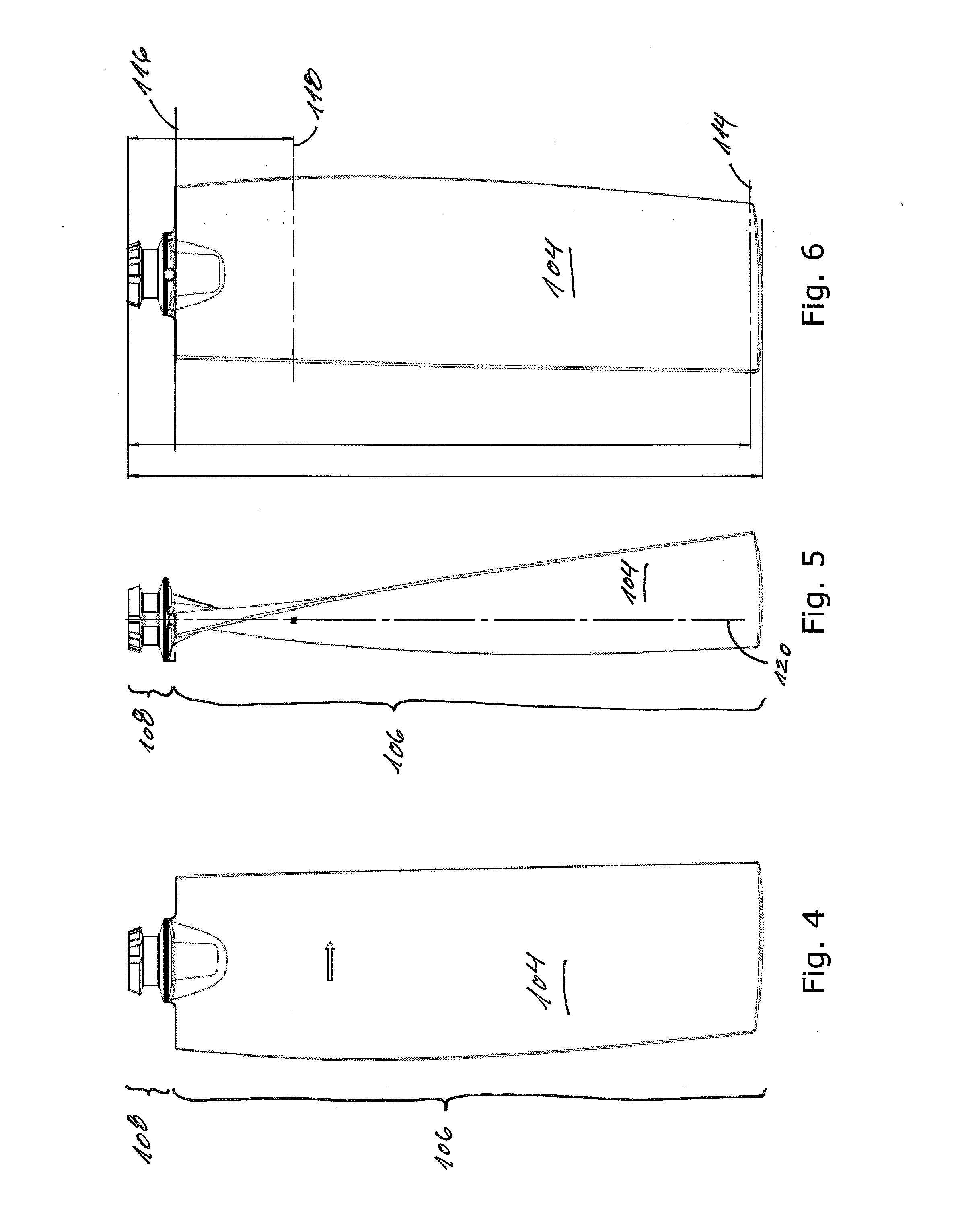

[0004]In a FIRST aspect the present invention relates to an engine cooling fan comprising a hub and a plurality of blades each of which extends away from the hub, wherein the hub defines a rotation axis about which the hub is adapted to rotate during operation; wherein each blade defines an attachment part, an air moving part, and a center line extending in a longitudinal direction of the blade between a tip end and a hub end of the blade; and wherein at least a first part of the center line extends in a direction transverse to a normal of the rotation axis of the hub.

[0005]In the context of the present invention, the term ‘engine cooling fan’ shall be understood as any fan which is suitable for cooling an engine, either by cooling a radiator which is used to cool a cooling medium that is circulated between the radiator and the engine and / or by cooling the engine directly.

[0006]The hub will typically be adapted to be connected or fastened to an axle which is rotated so as to cause t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com