Hose Reel Rewind Speed Control

a technology of speed control and hose reel, applied in the field of reels, can solve the problems of rewinding of its own accord in the most violent and rapid manner, damage to reel equipment or other items, and serious personal injury to personnel near the reel, and achieve the effect of improving the braking system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]Provided is a simple centrifugal braking device 20, 20a-20c, for use with spring motor hose reel assemblies.

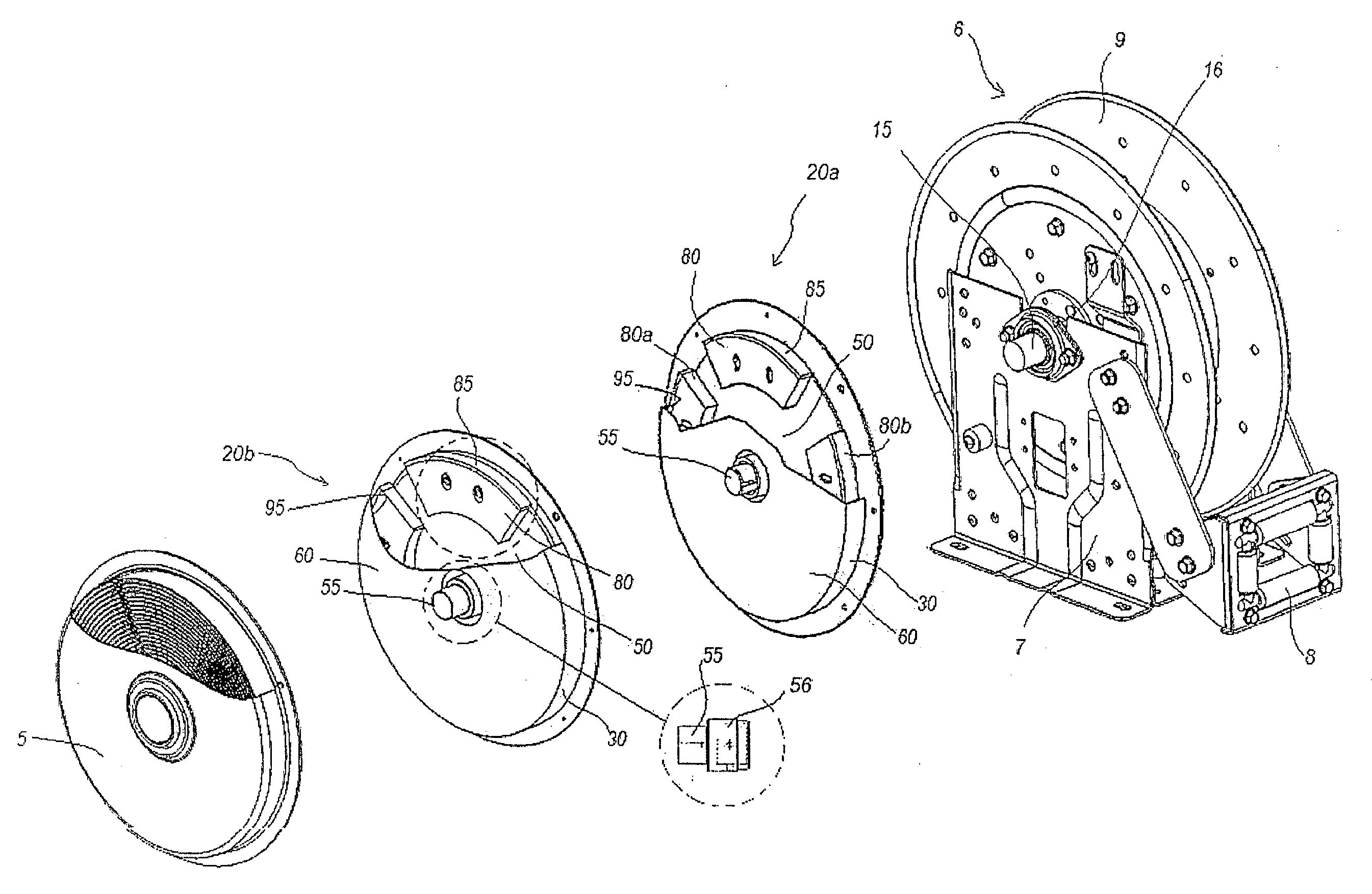

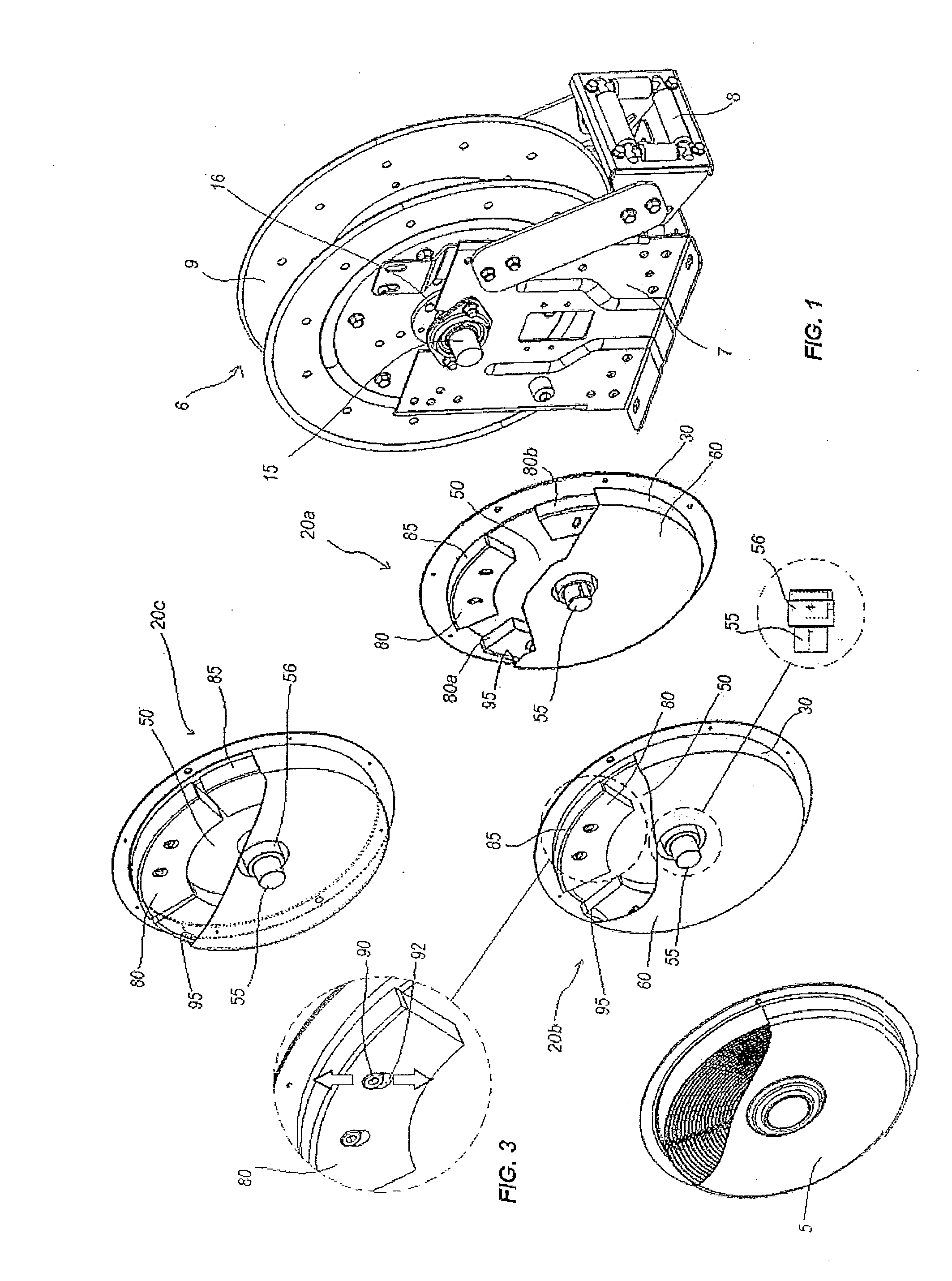

[0032]The braking cartridge is a centrifugal braking device 20, which acts as a rewind speed control means for spring motor hose and cable reels 6 of the type shown in FIG. 1. The braking device 20 is mounted on a hub shaft 15 via a hub bearing 16. The hub shaft 15 is associated with the reel 6 such that the braking device 20 controls the reel 6 rotational speed. The centrifugal braking device 20 comprises a drum 30 that comprises a stator 30 by which a rotating disc 50 is coupled to a brake device shaft 55, which is in line with the reel hub shaft 15 and is contained within the drum 30.

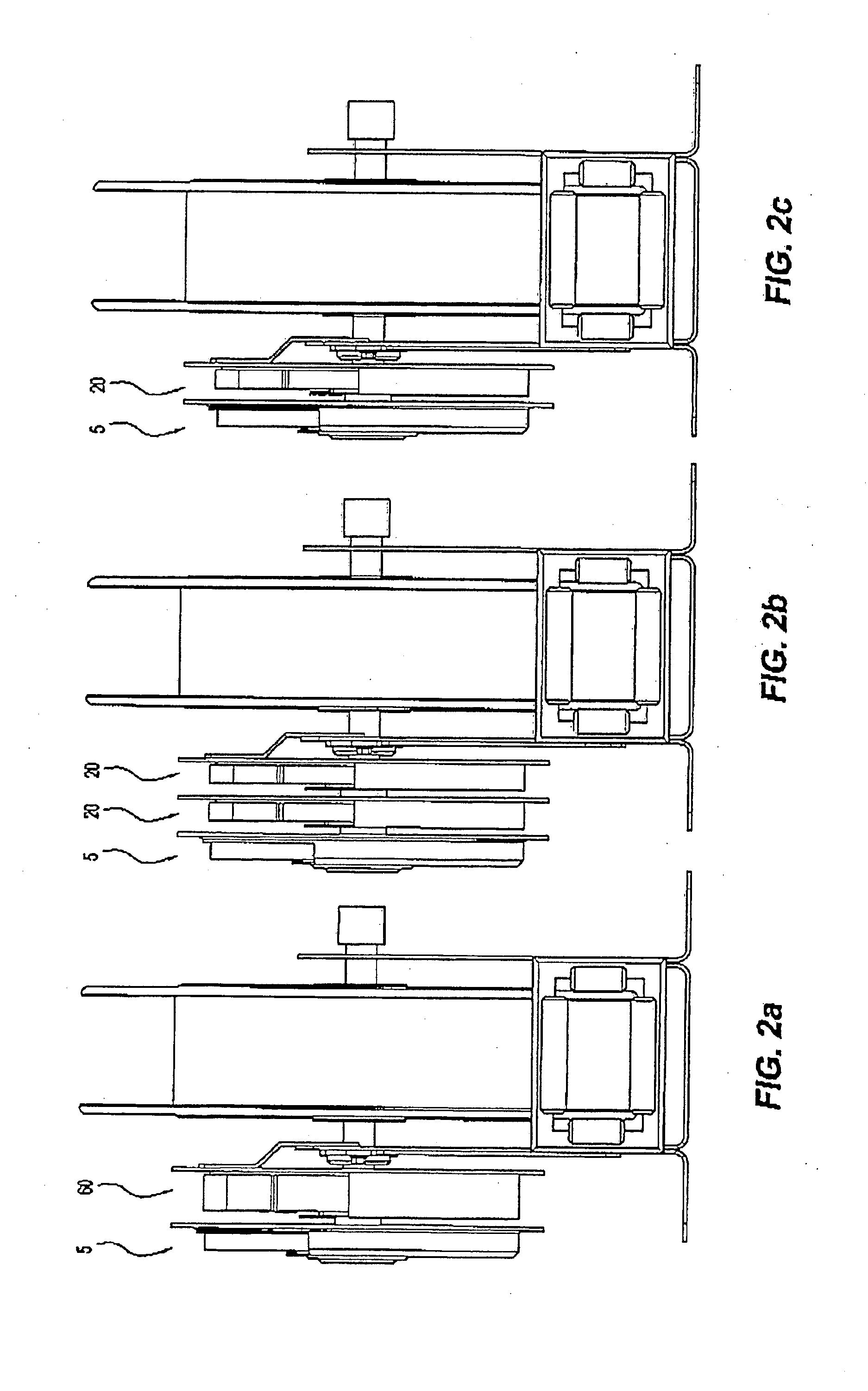

[0033]The embodiment of the disclosure as shown in FIG. 1 utilizes one or two braking cartridges 20a, 20b, each having a drum 30, preferably of similar dimensions to a coaxially mounted spring cartridge 5 for ease of integration should a unitary spring cartridge and brake cartridge assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com