Cryogen pump

a cryogen pump and liquid nitrogen technology, applied in the field of cryogenic pumps, can solve the problems of additional handling difficulties of liquid nitrogen, difficult to fill a volume, and the temperature of cryogen fluid is not quite boiling, so as to reduce or eliminate the effect of ambient temperatur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

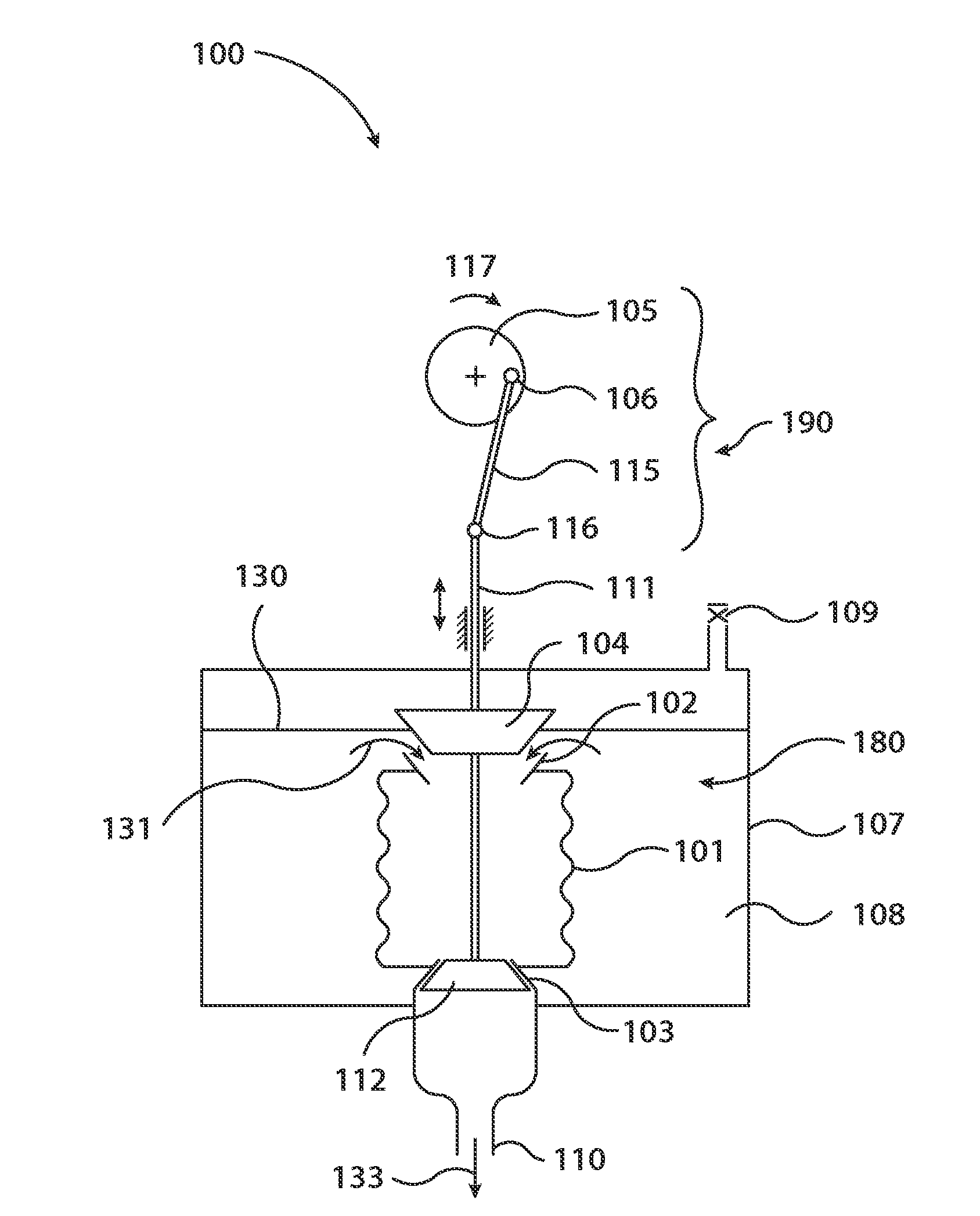

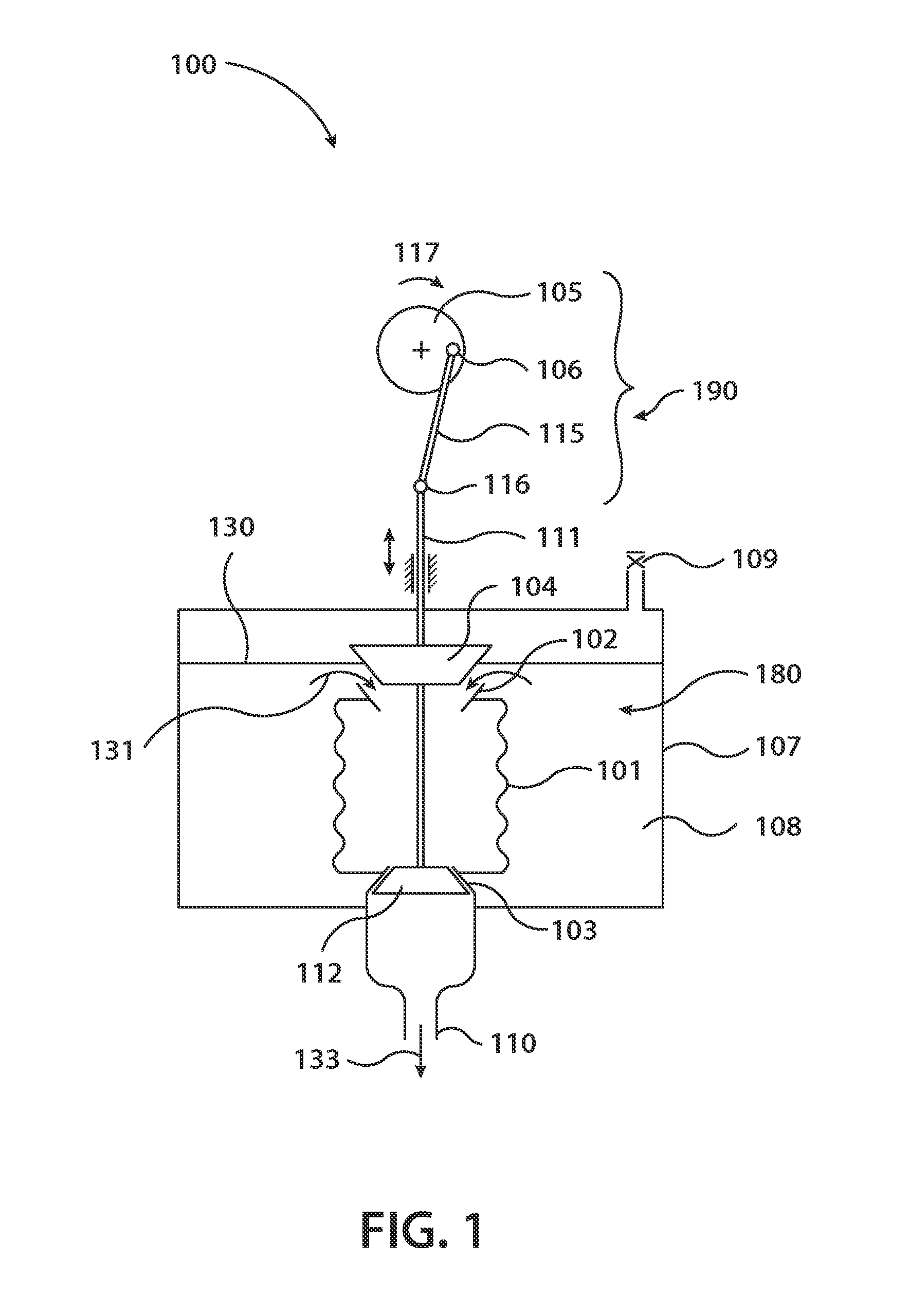

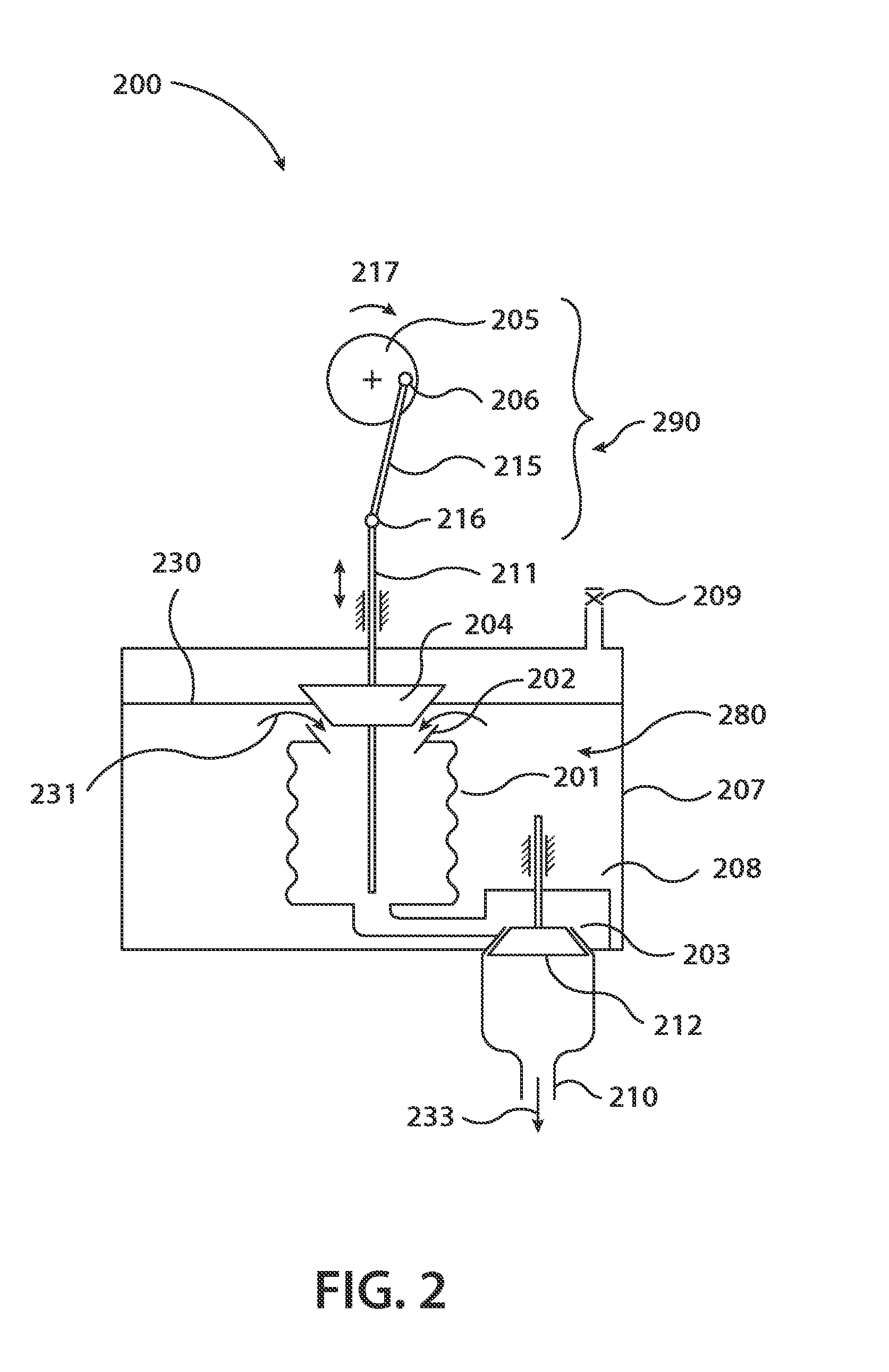

[0032]Reference will now be made in detail to embodiments of the present invention, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to the like elements throughout. The embodiments are described below to explain the present invention by referring to the figures.

[0033]The drawings are generally not to scale. For drawing clarity, non-essential elements may have been omitted from some of the drawings.

[0034]Although the following text sets forth a detailed description of at least one embodiment or implementation, it is to be understood that the legal scope of protection of this application is defined by the words of the claims set forth at the end of this disclosure. The detailed description is to be construed as exemplary only and does not describe every possible embodiment since describing every possible embodiment would be impractical, if not impossible. Numerous alternative embodiments and / or implementations are both contemplated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com