Fully insulated heat sealed soft cooler bag and method

a cooler bag and fully insulated technology, applied in domestic cooling devices, paper/cardboard containers, lighting and heating devices, etc., can solve the problems of bags not being properly insulated, bags prone to leakage, and not having drain valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

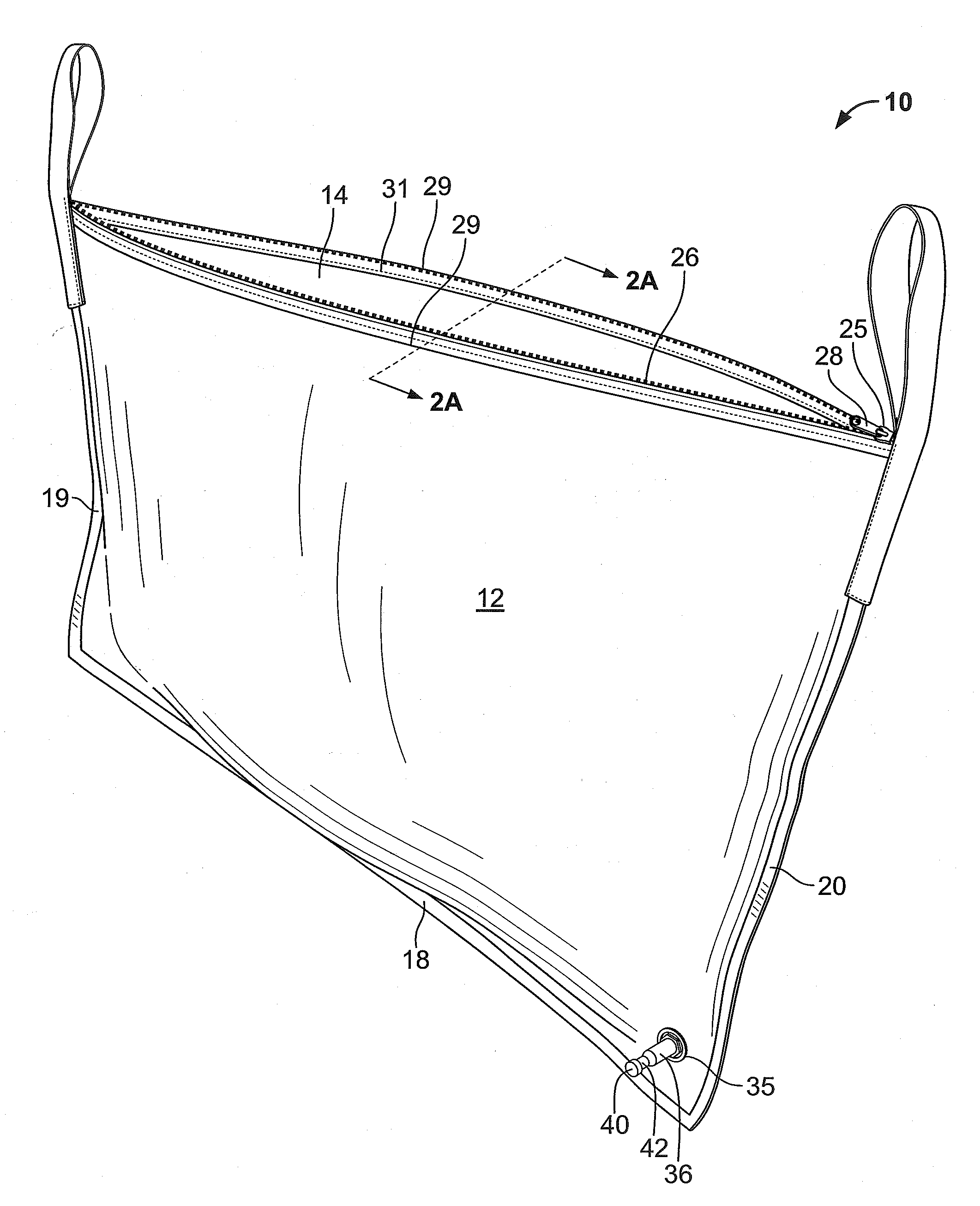

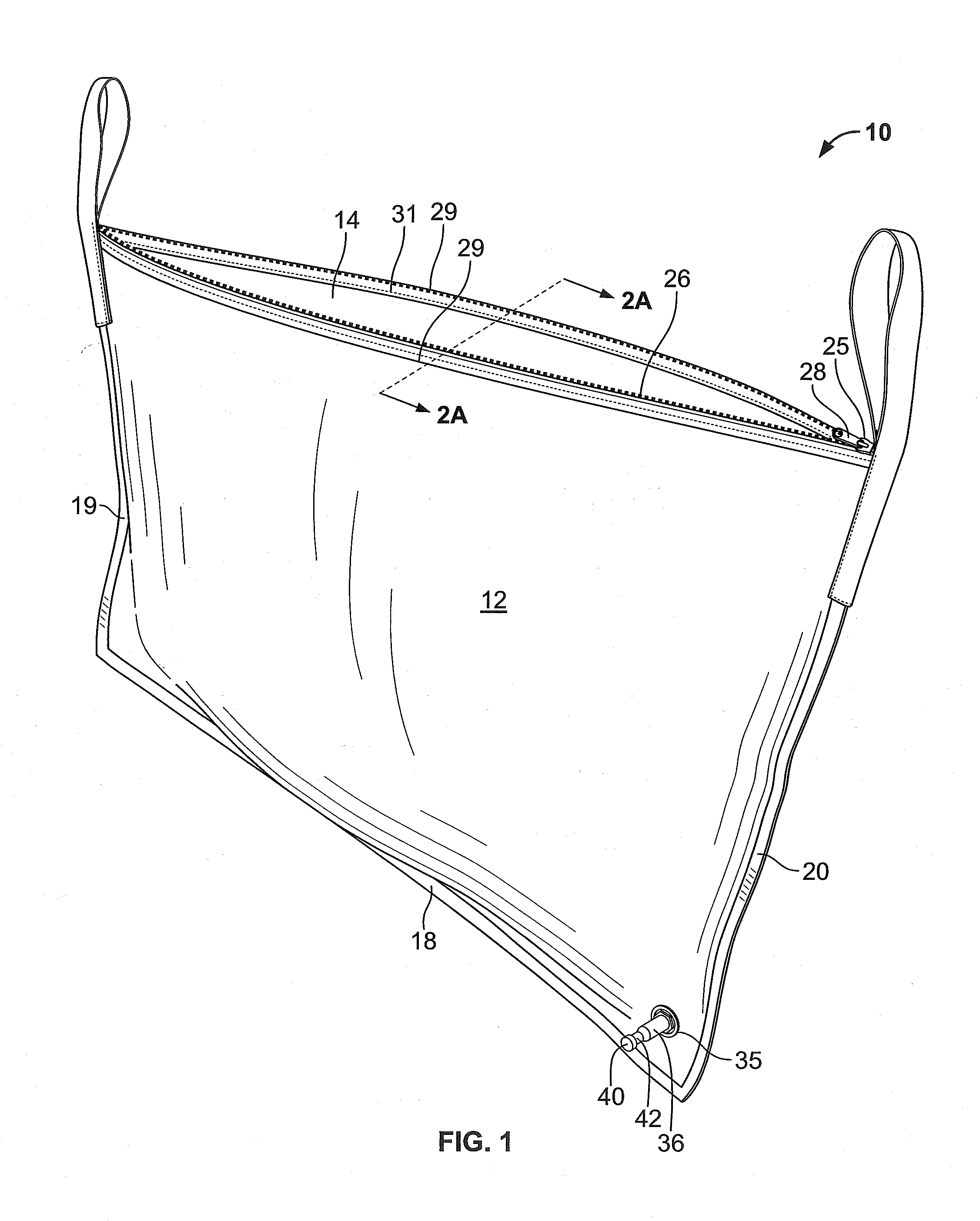

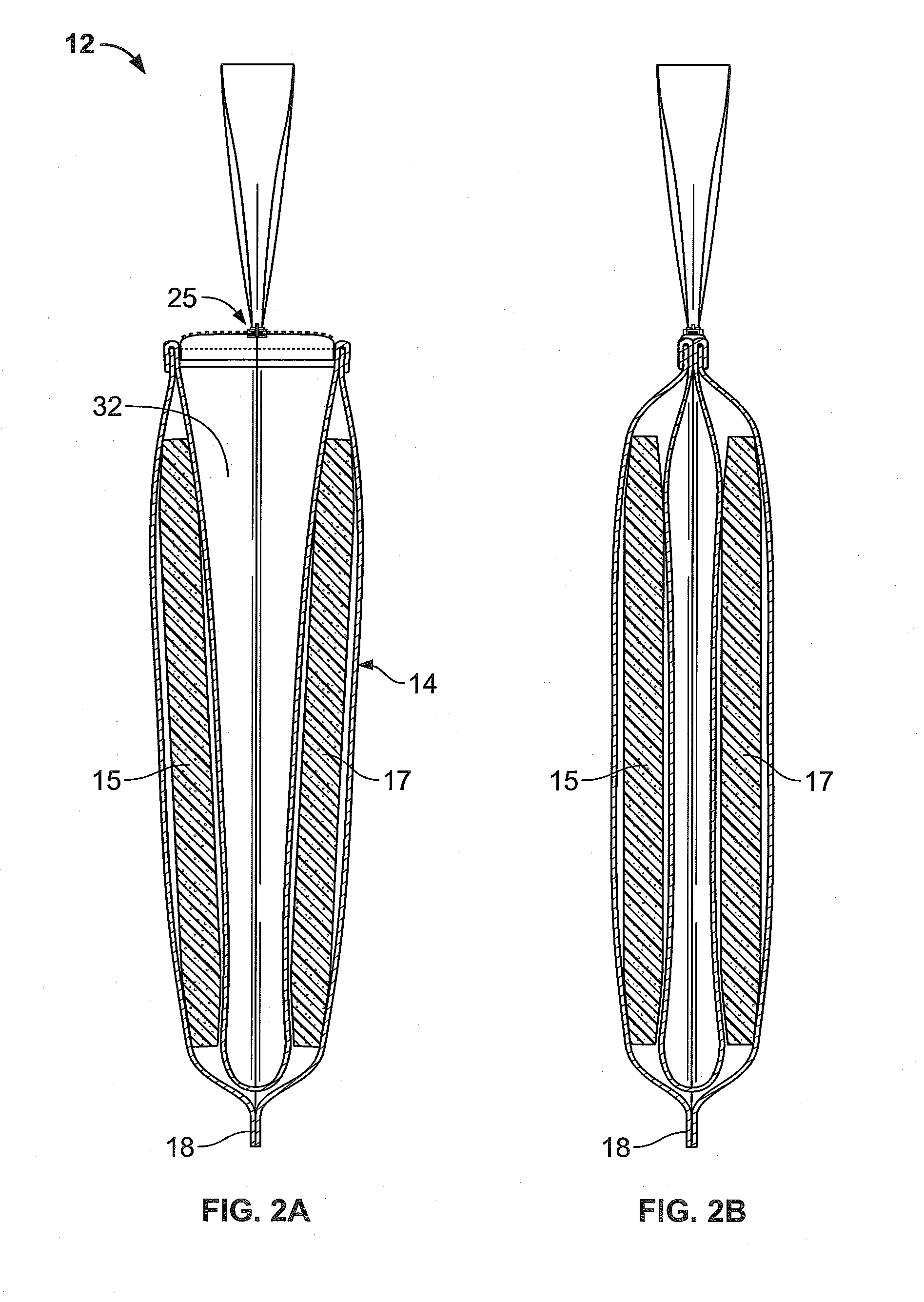

[0013]The preferred embodiment of the cooler bag of the present invention is shown in FIGS. 1, 2A, 2B, 3 and 4 inclusive. The cooler bag 10 comprises two compartments 12 and 14, as shown in FIGS. 2A and 2B with each compartment 12 and 14 enclosing a layer of insulation preferably in the form of a solid sheet of closed cell foam insulation 15 and 17 with each sheet of insulation 15 and 17 being essentially identical in composition and selected from the group consisting of fiberglass, polyurethane or expanded polystyrene and having a minimum thickness of about one inch in dimension. Each insulation sheet 15 and 17 should consist of a multiplicity of closed cells of relatively high density.

[0014]The bag 10 and each of its two compartments 12 and 14 is formed from a composition of flexible plastic, preferably fiber interlaced polyvinyl chloride (PVC). The compartments 12 and 14 of the bag 10 are formed with each compartment surrounding a sheet of insulation 15 and 17, preferably by heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com