Roll stand for absorbing rolling forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

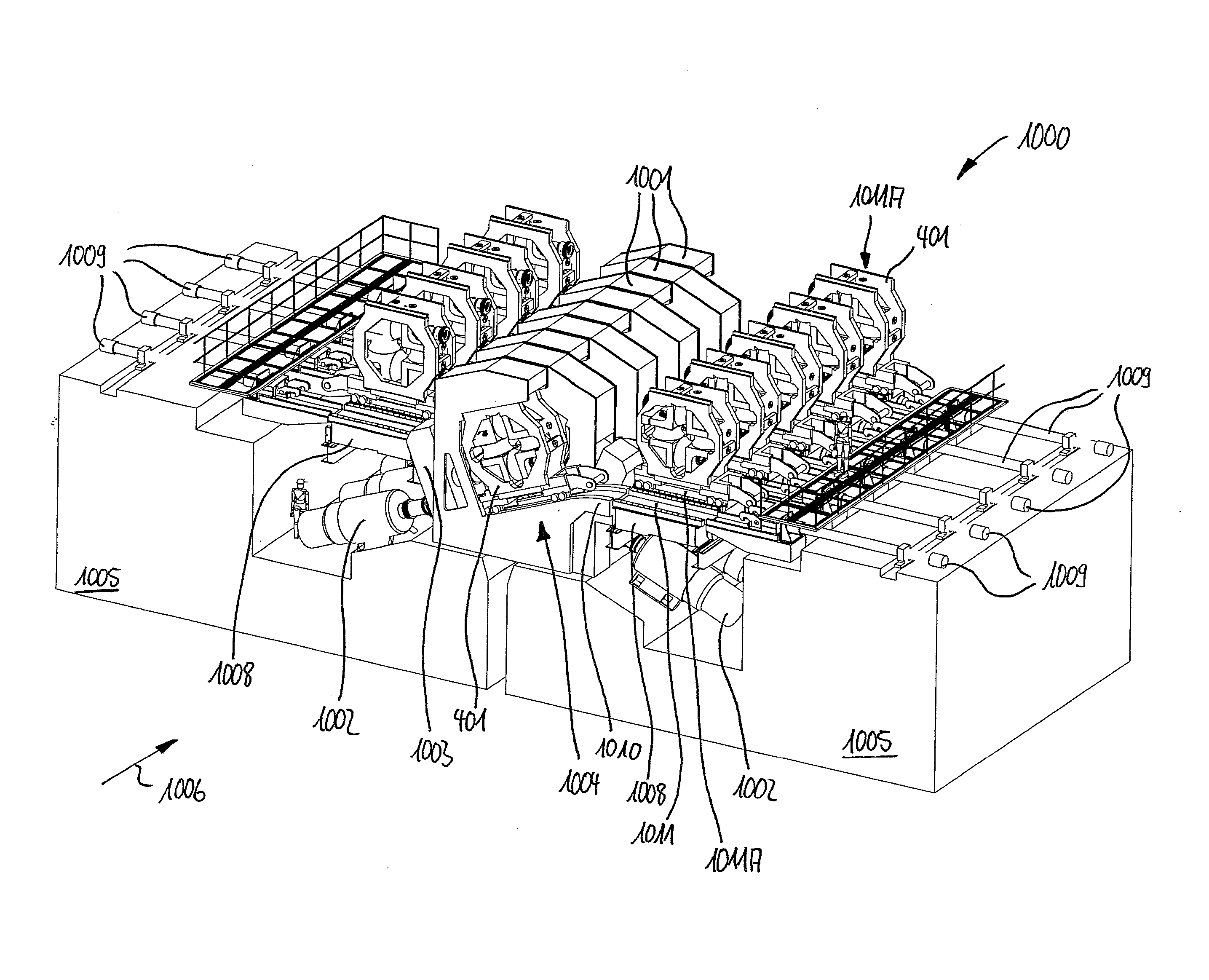

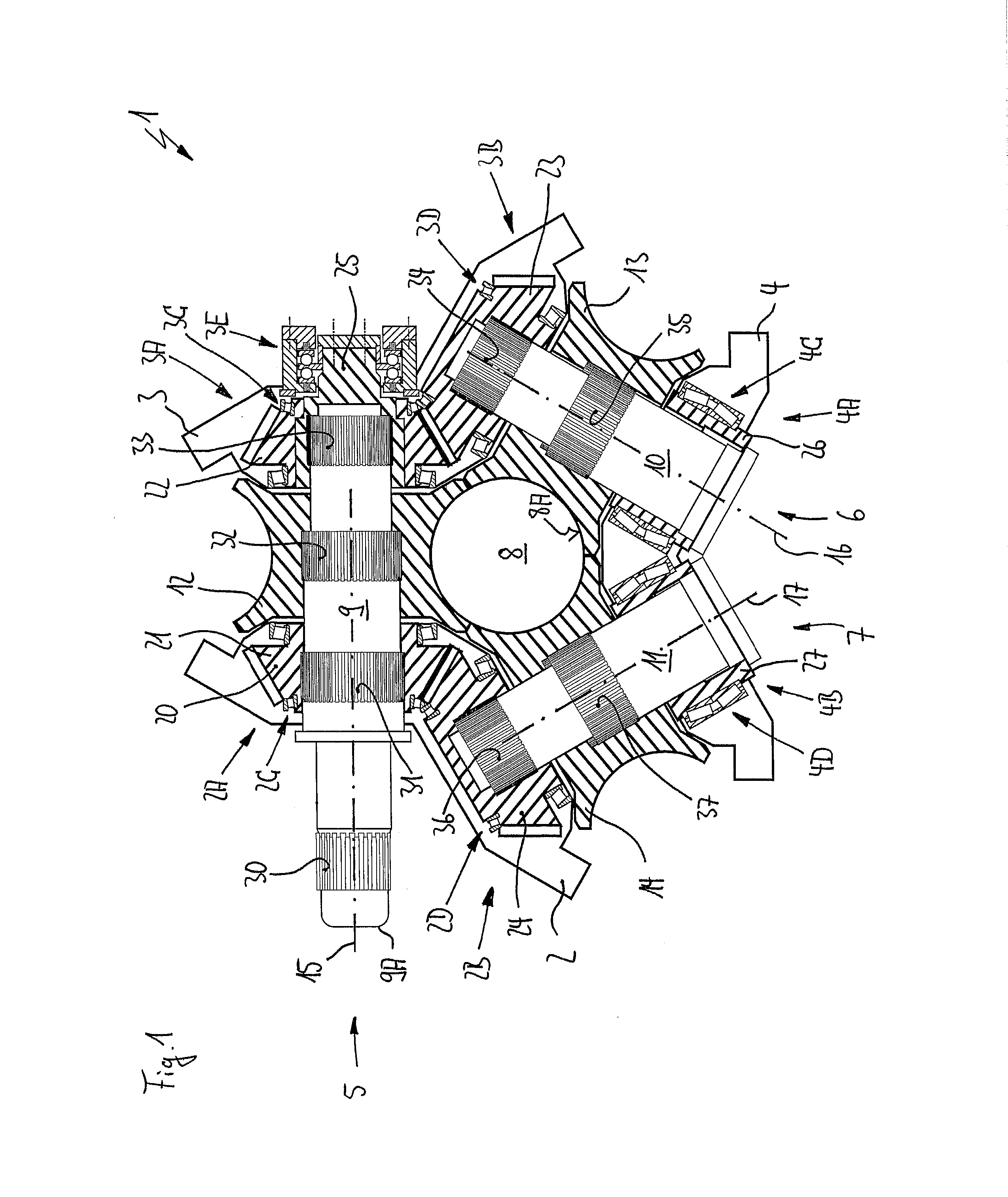

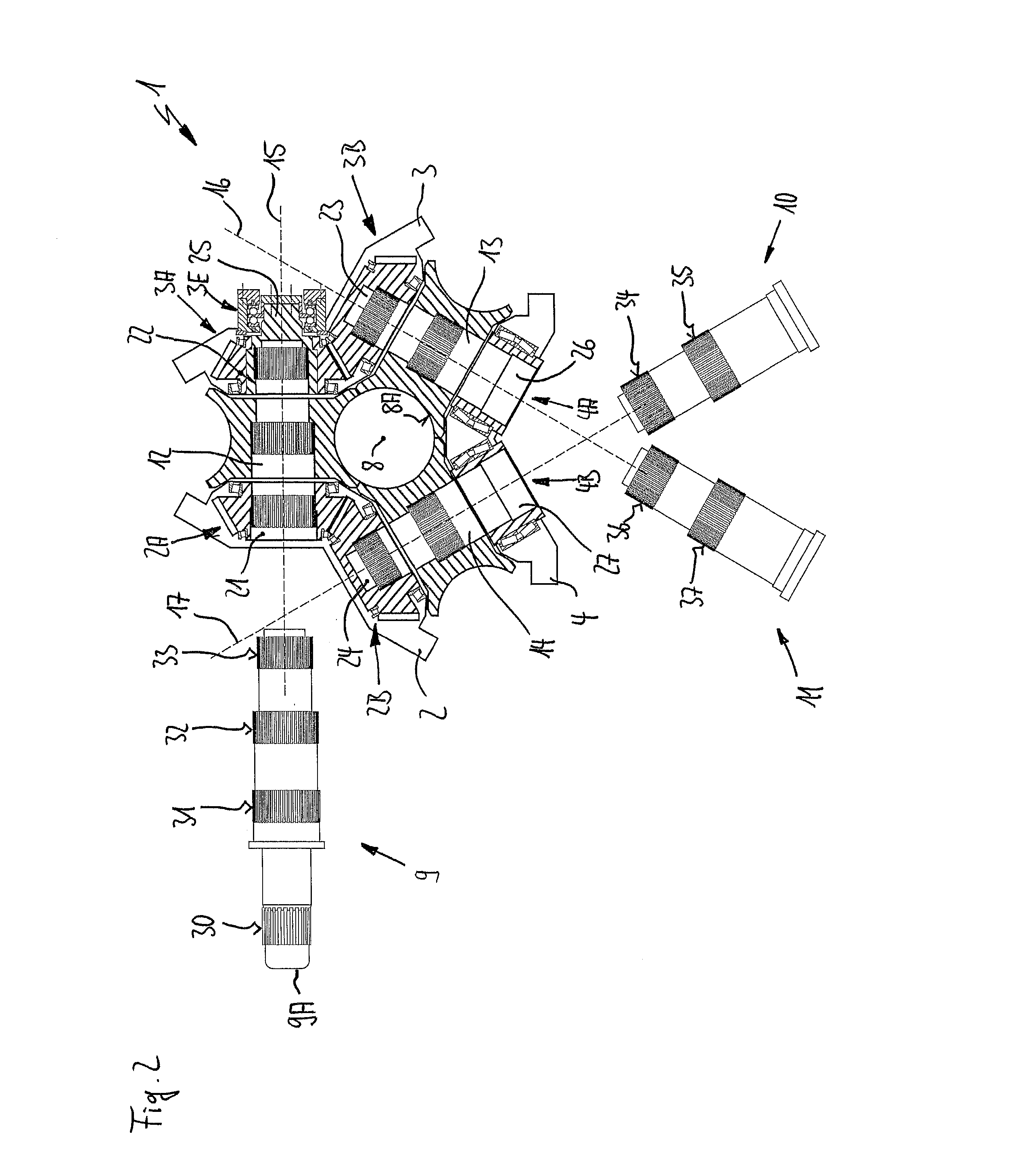

[0062]In the first exemplary embodiment shown in FIGS. 1 to 4, a roll stand 1 comprises a total of three stand bodies 2, 3, and 4, in which three rolls 5, 6, and 7 are mounted concentrically about a rolling line 8 or an axially extending processing segment, whereby the three rolls 5, 6, and 7 form a roll pass 8A for rolling a rolled material, not shown here.

[0063]Each of the rolls 5, 6, and 7 consists of a roll shaft 9, 10, and 11, respectively, and a related roll element 12, 13, and 14, respectively, whereby these three roll elements 12, 13, and 14 form the roll pass 8A, as can be seen particularly well in the representation according to FIGS. 1 to 3.

[0064]The stand bodies 2, 3, and 4 are configured with an angle, in each instance, so that they make a corresponding bearing seat 2A, 2B, 3A, 3B, and 4A and 4B, respectively, available for two of the three roll shafts 12, 13, and 14.

[0065]As is particularly evident according to the representation according to FIG. 4, the first stand bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com