Air compressor having chambered piston head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

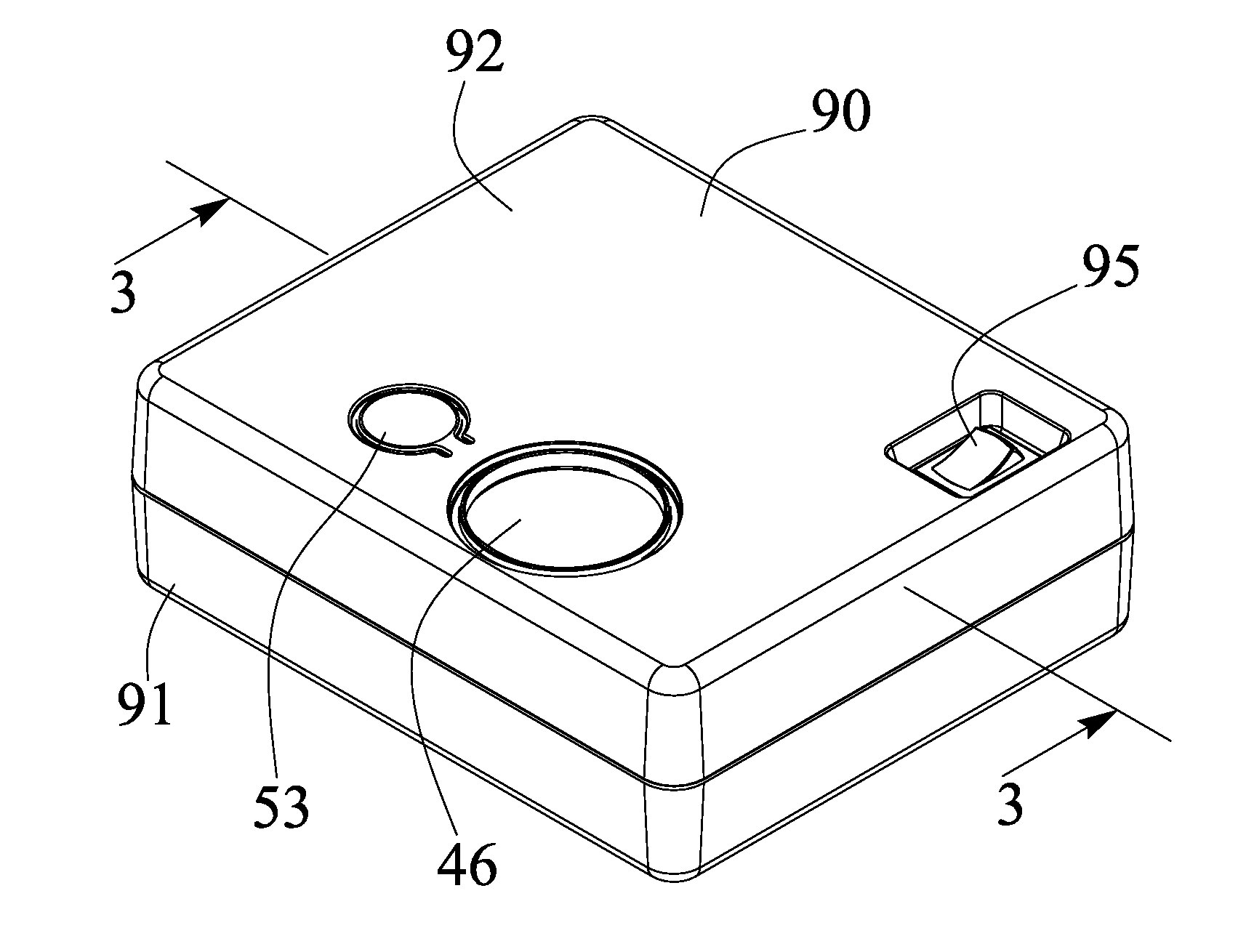

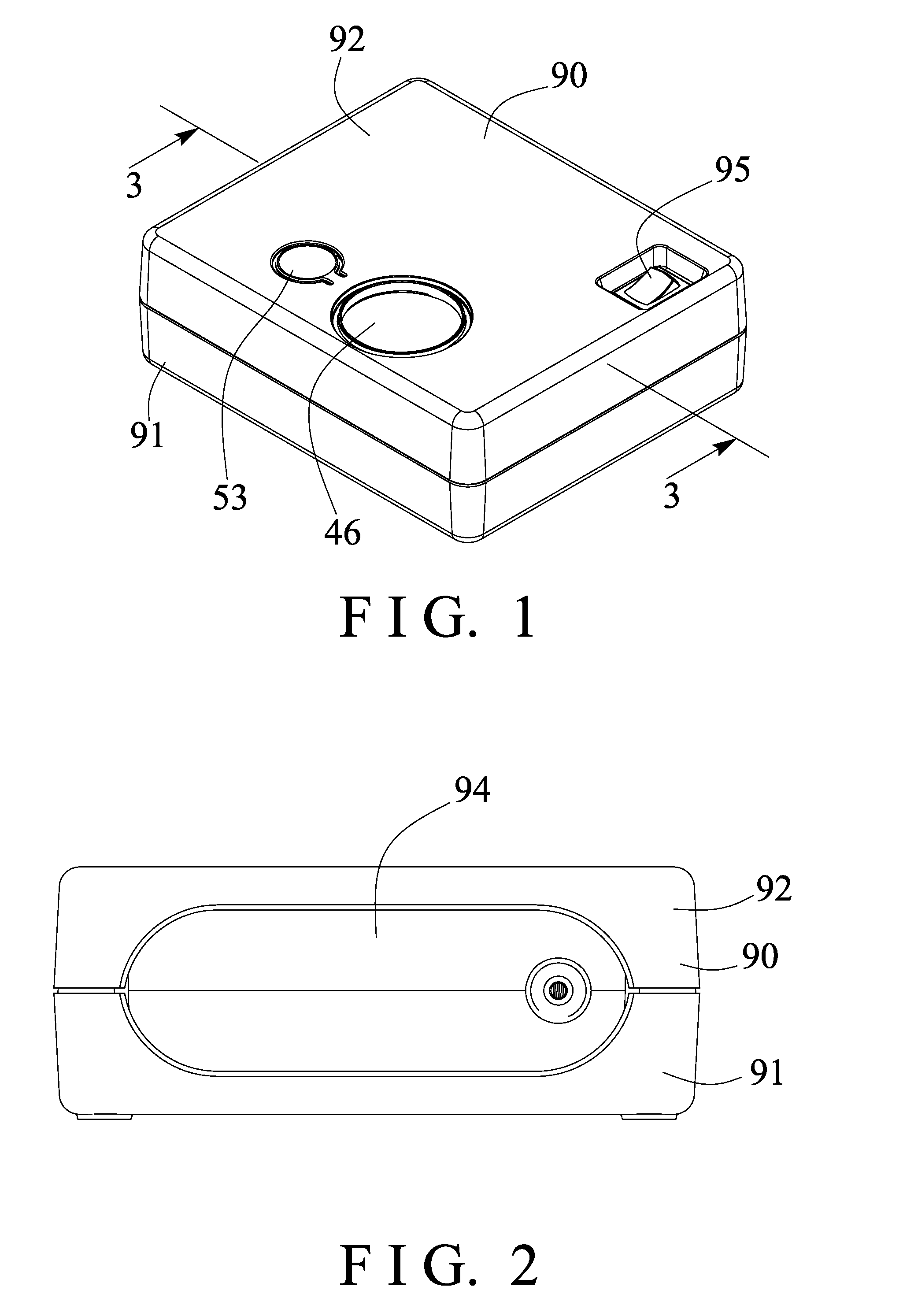

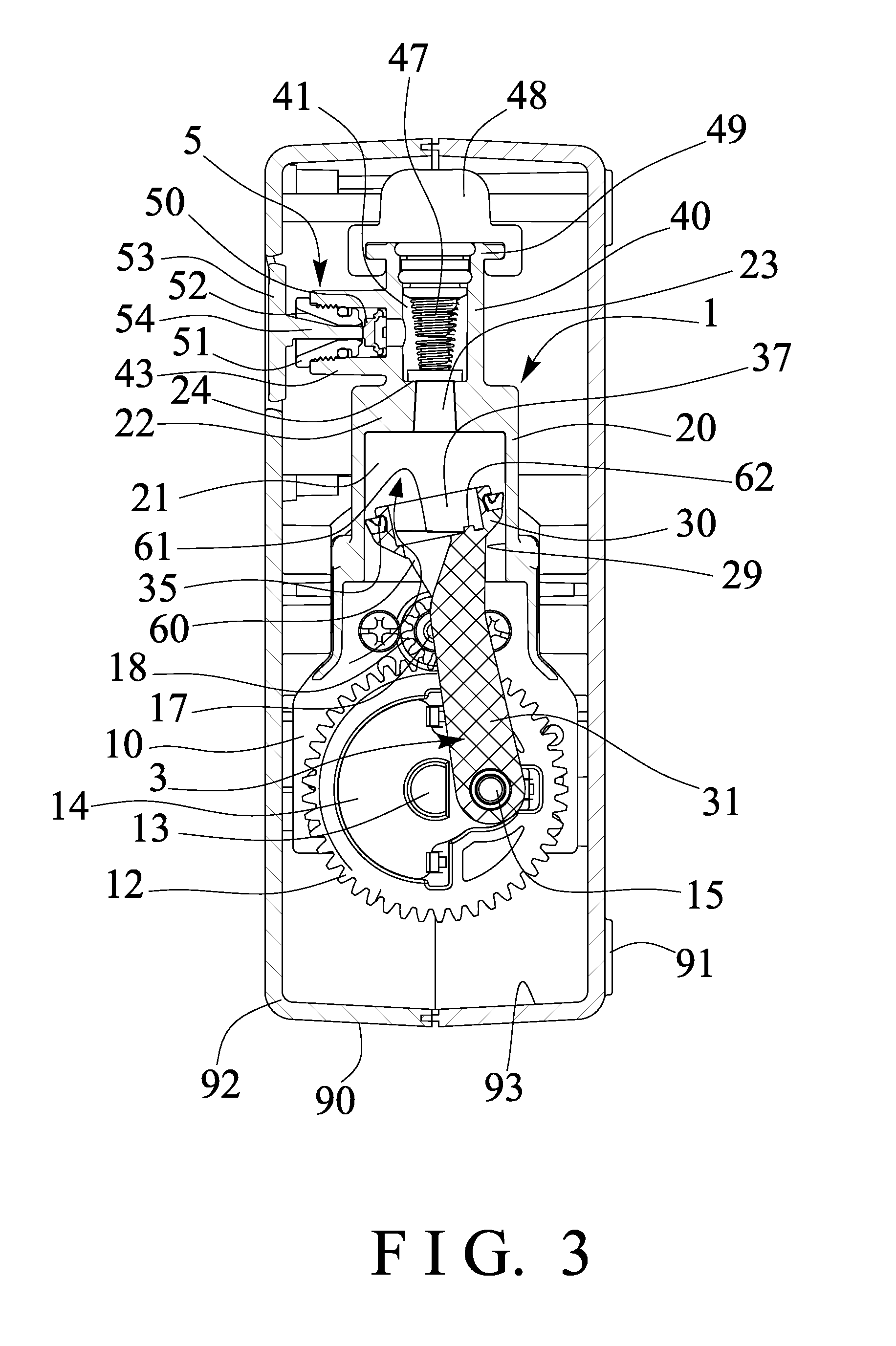

[0028]Referring to the drawings, and initially to FIGS. 1-4, an air compressor assembly in accordance with the present invention comprises an outer receptacle or housing or container 90 including a supporting lower or bottom container member 91 and an upper covering member 92 openably attached or mounted or secured or coupled or anchored or retained or position together to form and to provide a chamber or compartment or space 93 in the container 90 for receiving or accommodating an air compressor device 1. As shown in FIGS. 3-5, the air compressor device 1 includes a supporting base 10 including a supporting plate 11 and a cylinder housing 20 provided on or extended from the supporting plate 11 and preferably, but not necessarily formed integral with the supporting plate 11.

[0029]For example, the supporting plate 11 and the cylinder housing 20 may be formed integral with each other, as shown in FIG. 5, with the molding or mold-injection processes, for example, or alternatively, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com