Coil spring for bed mattress having means for preventing frictional noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0048]FIG. 5 is a cross-sectional and perspective view showing a first embodiment of the coil spring of the spring assembly according to the present invention.

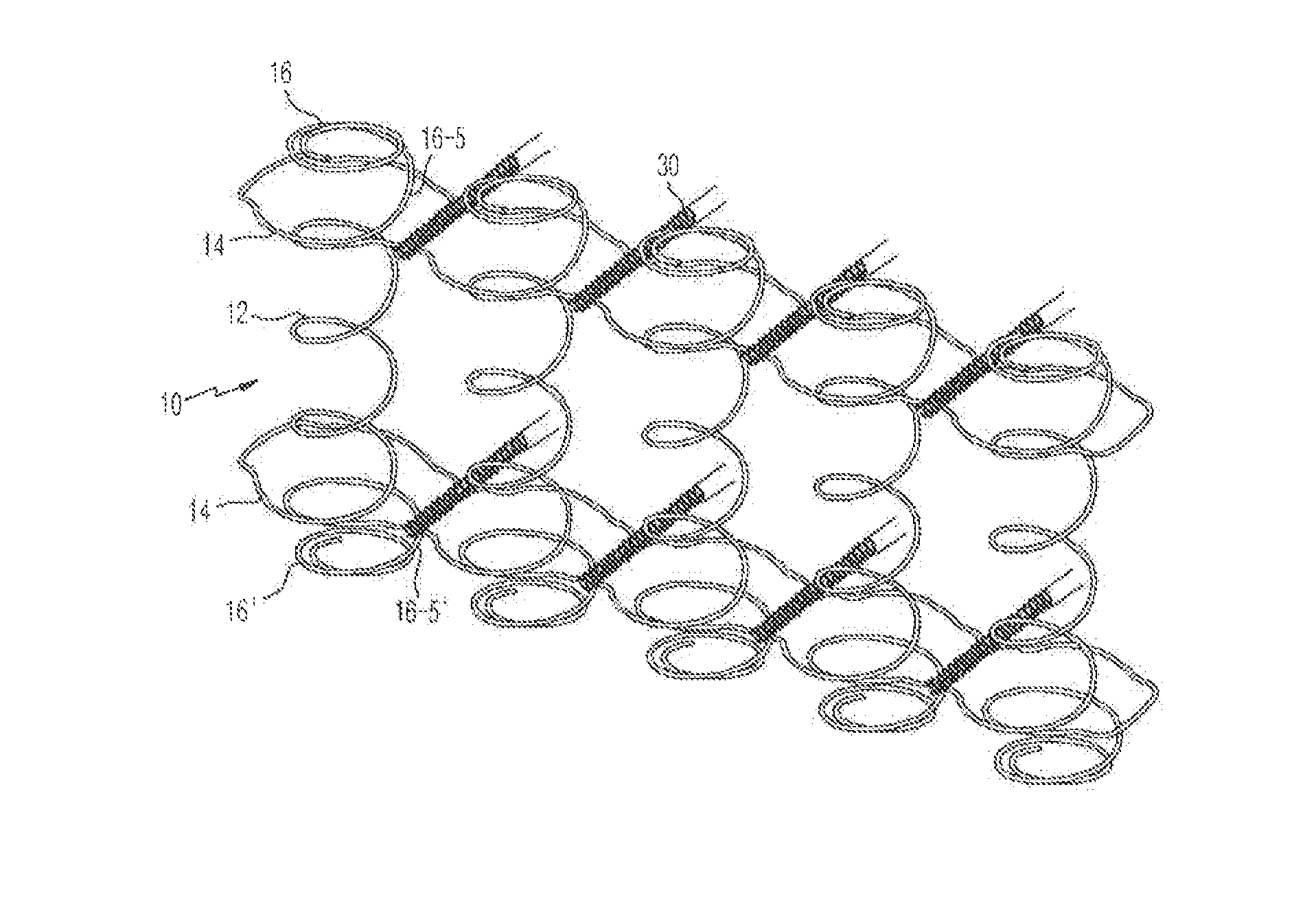

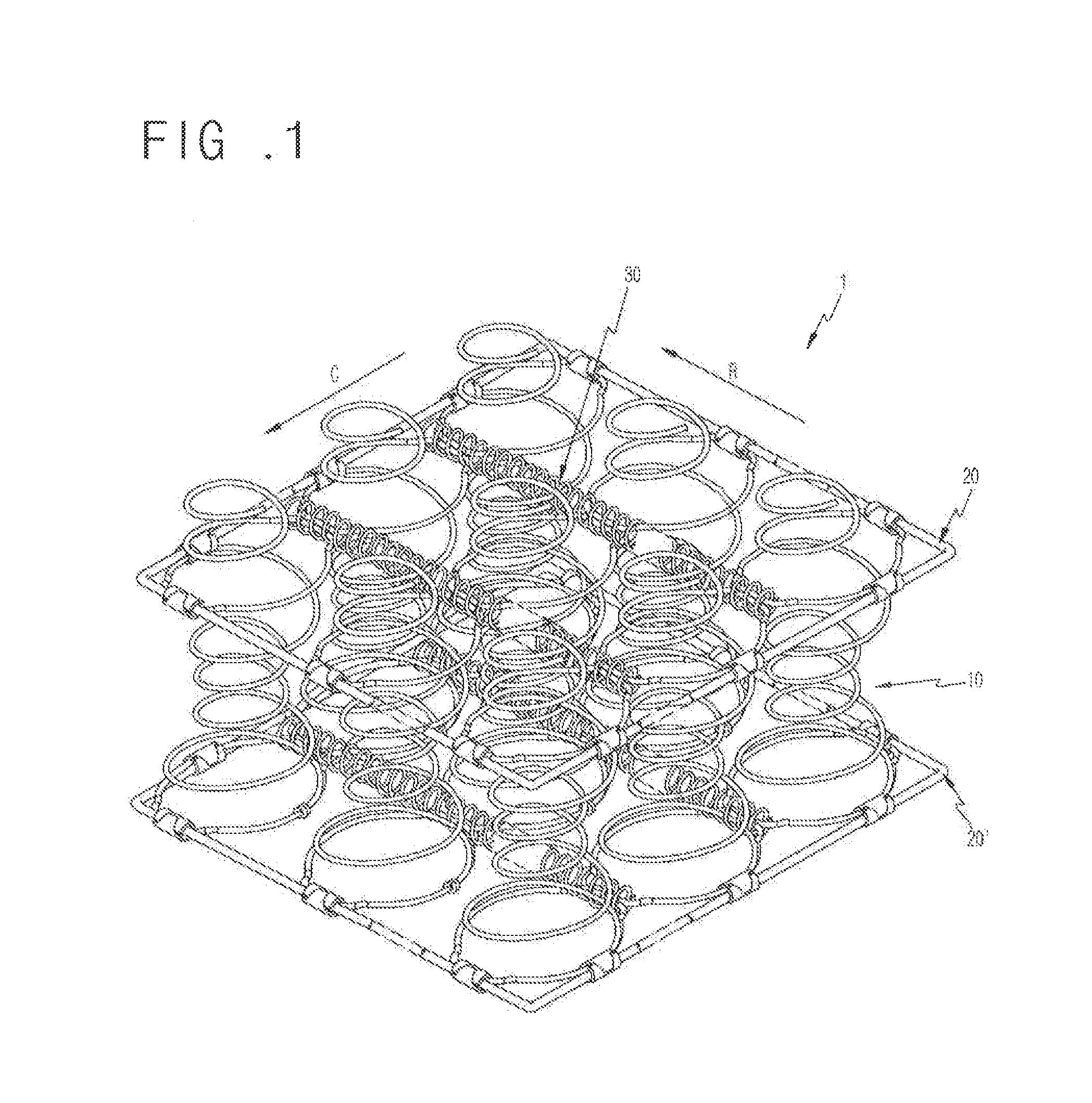

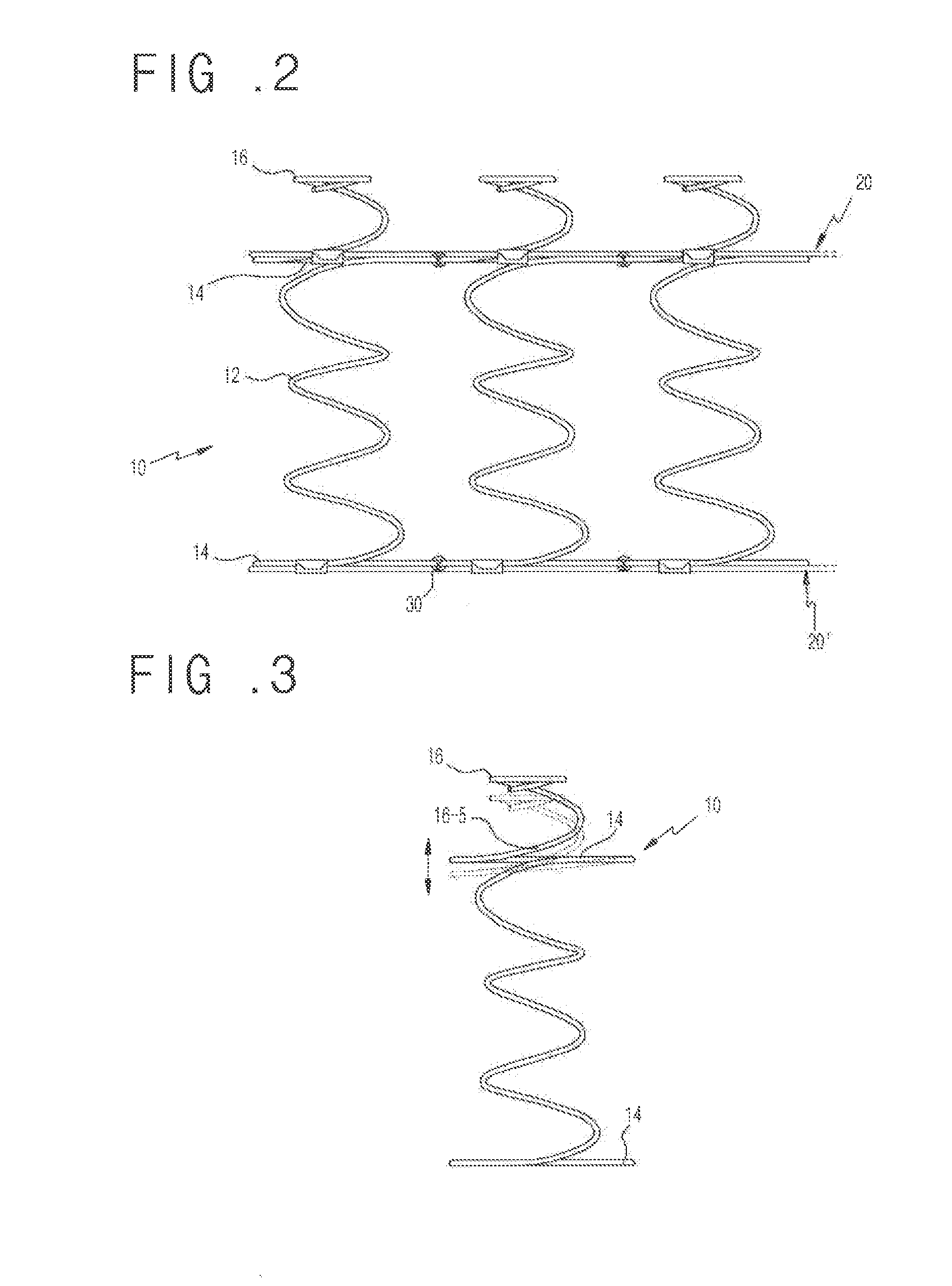

[0049]This embodiment of the present invention provides a coil spring for a bed mattress having means for preventing frictional noise which includes a body wiring portion 12 situated in the space between the upper edge member 20 and the lower edge member 20′, the end wiring portions 14 provided on both ends of the body wiring portion 12 and set within a range in which the upper and lower edge members 20 and 20′ are disposed, and at least one of the upper exposed wiring portion 16 extending from the end wiring portion 14 so as to be exposed from the upper edge member 20 and the lower exposed wiring portion 16′ extending from the end wiring portion 14 so as to be exposed from the lower edge member 20′.

[0050]Here, contact wiring portions 16-5 and 16-5′ which abut to the end wiring portions 14 while the upper and lower exposed wir...

embodiment 2

[0057]FIG. 6 is a cross-sectional and perspective view showing a second embodiment of the coil spring of the spring assembly according to the present invention.

[0058]This embodiment of the present invention provides a coil spring for a bed mattress having means for preventing frictional noise which includes a body wiring portion 12 situated in a space between the upper edge member 20 and the lower edge member 20′, the end wiring portions 14 provided on both ends of the body wiring portion 12 and set within a range in which the upper and lower edge members 20 and 20′ are disposed, and the upper exposed wiring portion 16 extending from one of the end wiring portions 14 so as to be exposed from the upper edge member 20. Here, a contact wiring portion 16-5 which abuts to one of the end wiring portions 14 while the upper exposed wiring portion 16 is being compressed has a contact surface A which is in contact with that end wiring portion 14, whereby frictional noise between the upper exp...

embodiment 3

[0065]FIG. 7 is a cross-sectional and perspective view showing a third embodiment of the coil spring of the spring assembly according to the present invention.

[0066]This embodiment of the present invention provides a coil spring for a bed mattress having means for preventing frictional noise which includes a body wiring portion 12 situated in a space between the upper edge member 20 and the lower edge member 20′, the end wiring portions 14 provided on both ends of the body wiring portion 12 and set within a range in which the upper and lower edge members 20 and 20′ are disposed, and the lower exposed wiring portion 16′ extending from one of the end wiring portions 14 so as to be exposed from the lower edge member 20′. Here, a contact wiring portion 16-5′ which abuts to one of the end wiring portions 14 while the lower exposed wiring portion 16′ is being compressed has a contact surface A which is in contact with that end wiring portion 14, whereby frictional noise between the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com