Method for determining the surface gloss of a colour standard

a technology of surface gloss and colour standard, which is applied in the direction of optical radiation measurement, instruments, spectrometry/spectrophotometry/monochromators, etc., can solve the problems of increasing the cost of determining the gloss of the surface, the difficulty of developing real analytical representations of the textured air/paint interface, and the difficulty of predicting formula quality,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

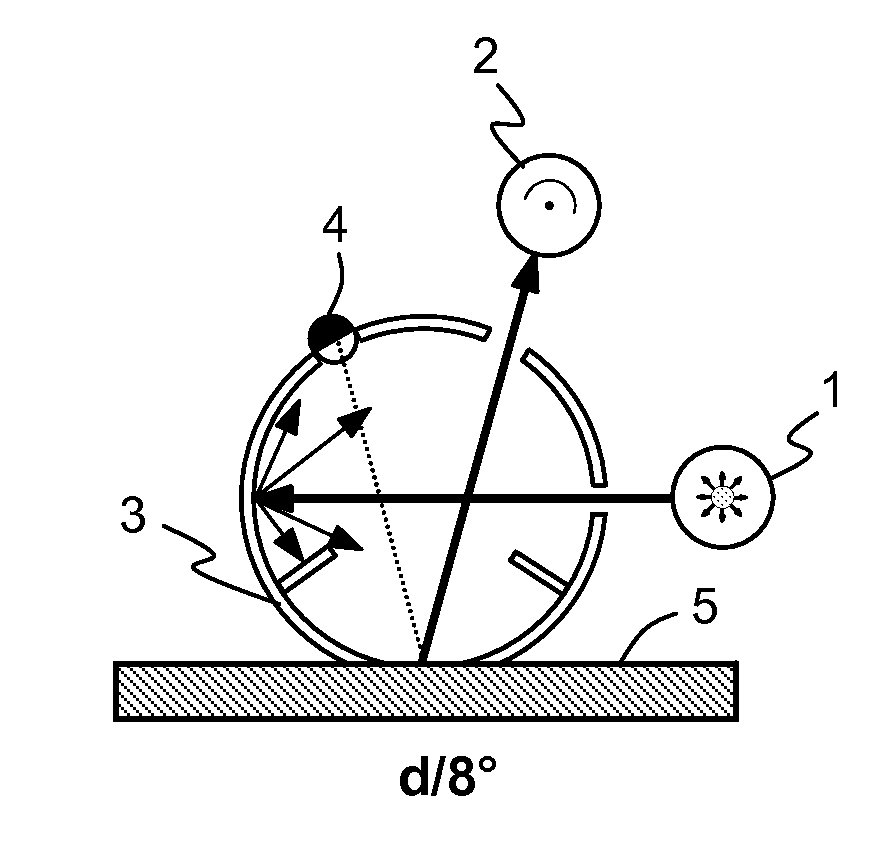

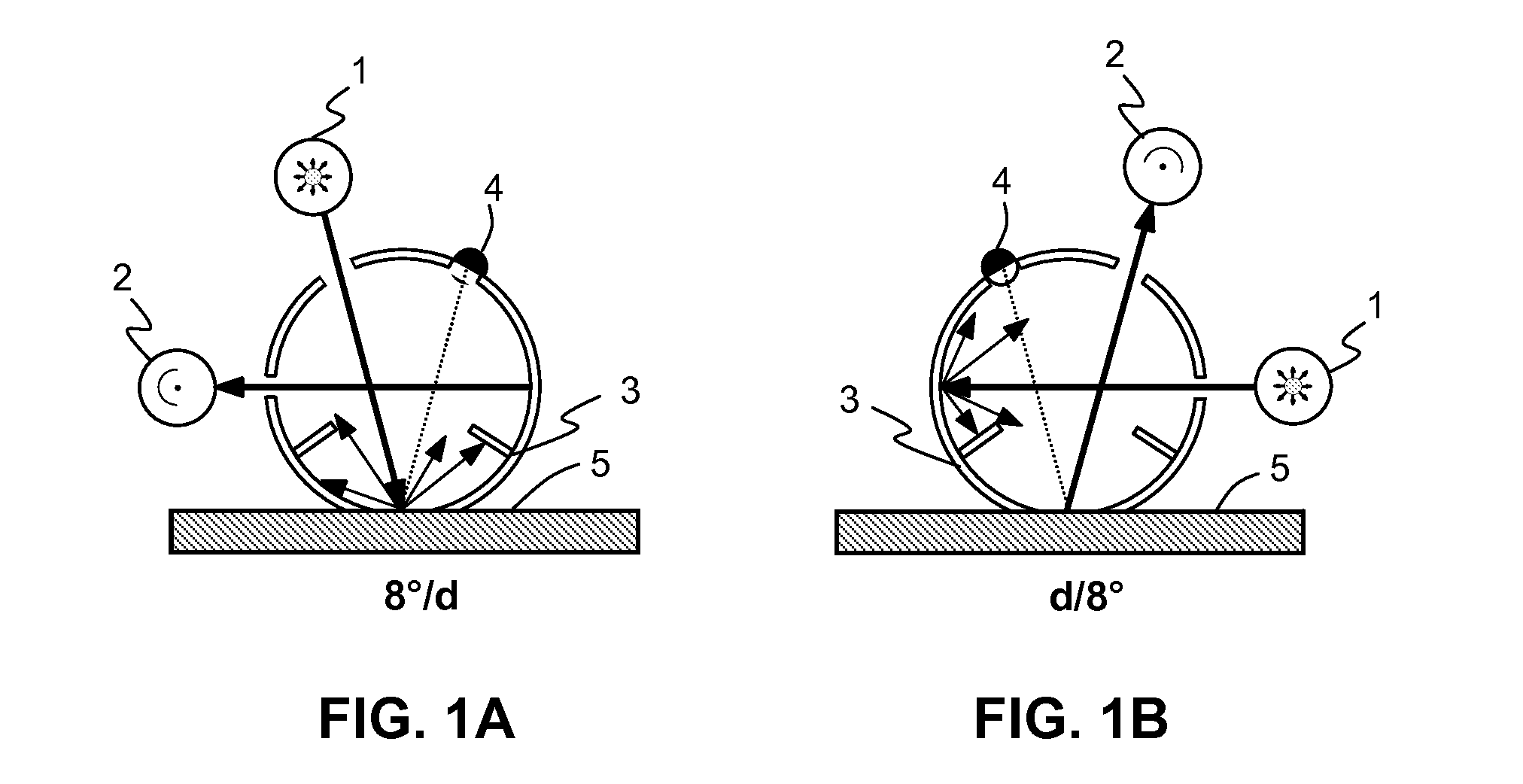

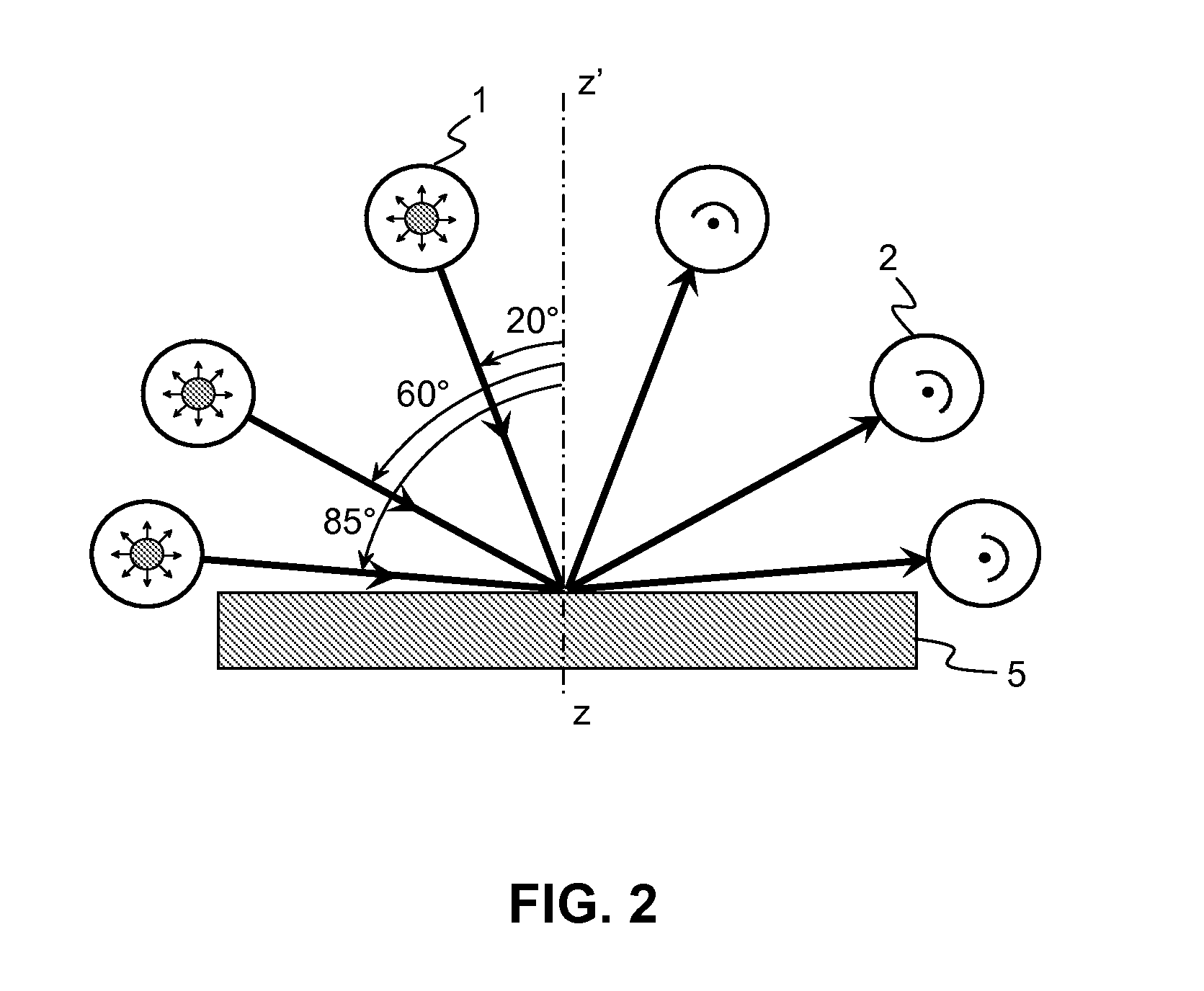

[0074]Two semi-glossy colour shades from the RAL 840-HR register (RAL 3000, RAL 7005), representing a well-accepted and typical collection of colour standards in industrial applications, have been selected to show the efficiency of the method of the present invention. The reflectance functions of the two selected colour standards have been experimentally determined within the visible spectral range. The commercial measurement instrument used for the colour development was equipped with a d / 8° measurement geometry and could be operated in the specular included (SPIN) and excluded (SPEX) modes. This was the same colour measurement instrument as used to determine the calibration function. The gloss values have been measured at the three recommended angles of 20°, 60°, and 85° using the same commercial gloss-meter that had been used to determine the calibration function. The calibration curve of the pair of instruments used (gloss-meter=micro TRI-gloss instrument of Byk-Gardner; colour ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength range | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com