Inkjet Printer

a technology of inkjet printer and inkjet printer, which is applied in the direction of printing, other printing apparatus, etc., can solve the problems of unnecessary micro droplets (satellites) being generated, productivity being lowered in some cases, so as to suppress the generation of satellites, and reduce the amount of ink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

Entire Configuration of Inkjet Printer

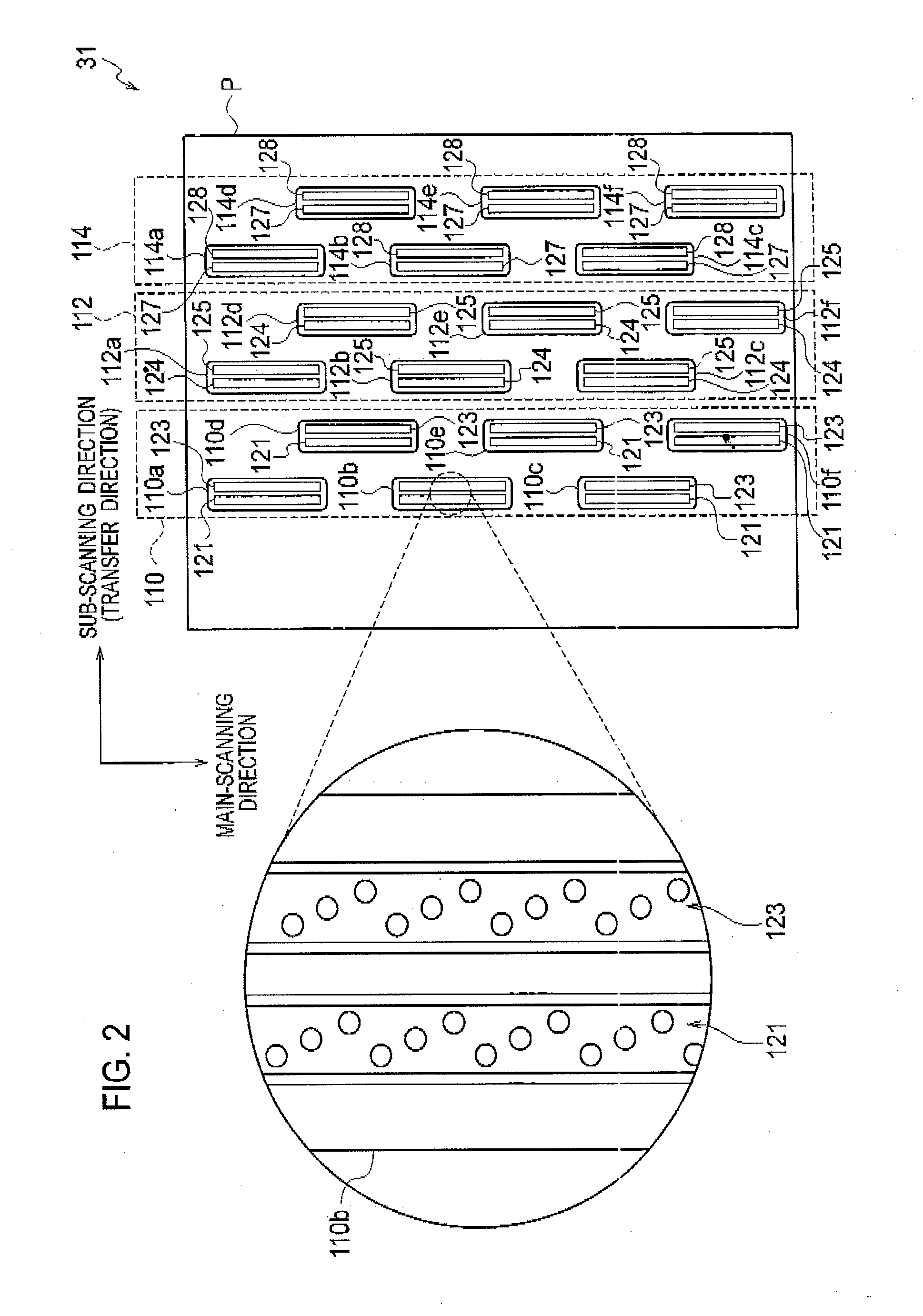

[0050]In this embodiment, a line-type inkjet printer which has inkjet heads aligned in a direction (main-scanning direction) orthogonal to a sheet transfer direction and performs printing on a sheet transferred on a transfer path by discharging an ink from a nozzle of the inkjet head on the basis of image data will be explained as an example.

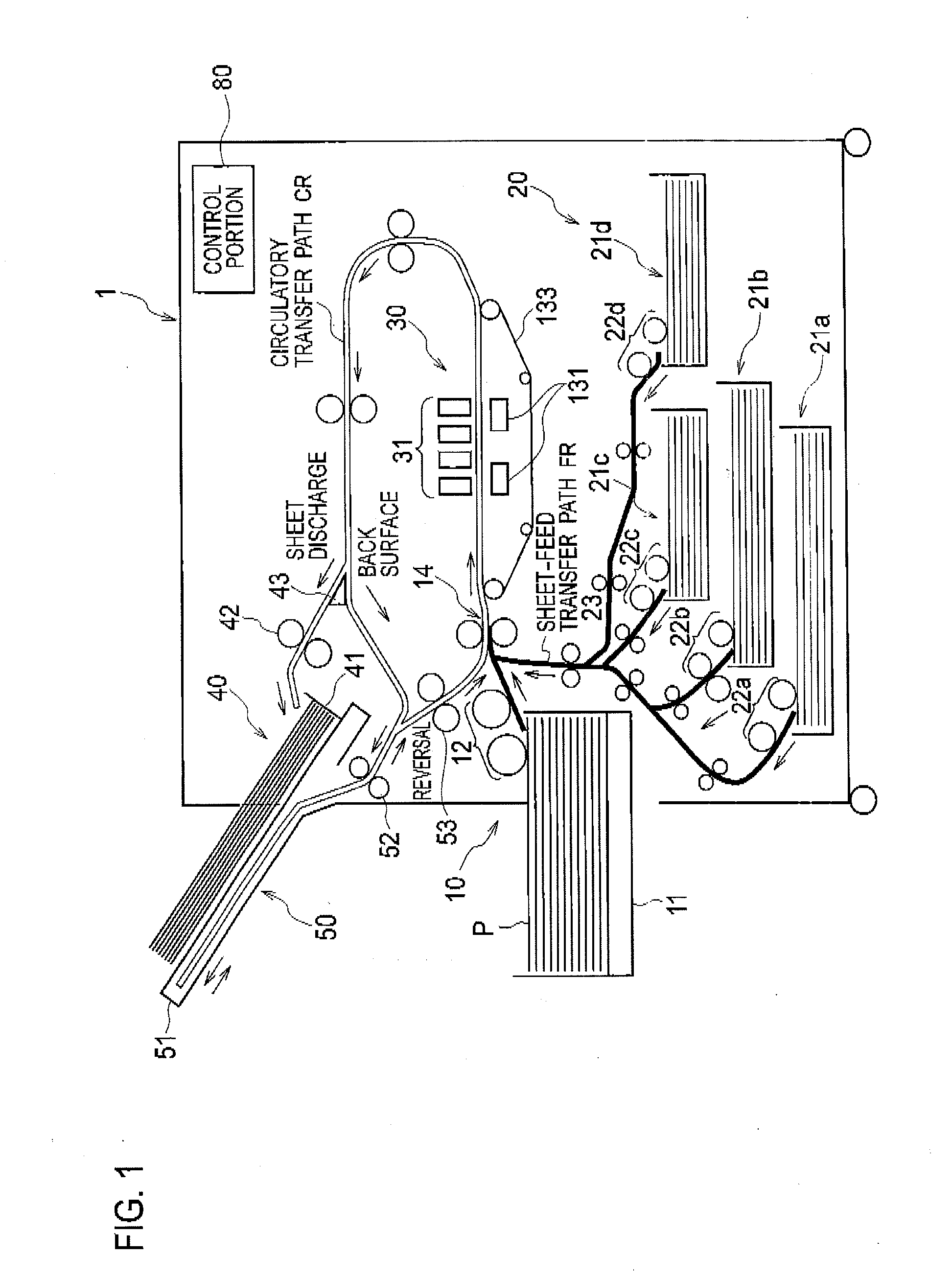

[0051]FIG. 1 is a configuration diagram illustrating a configuration of an inkjet printer 1.

[0052]As illustrated in FIG. 1, the inkjet printer 1 is provided with a side sheet-feed portion 10, an internal sheet-feed portion 20, a printing portion 30, a sheet-discharge portion 40, and a reversing portion 50.

[0053]The side sheet-feed portion 10 is provided with a sheet receiving tray 11, a primary sheet-feed portion 12, and a secondary sheet-feed portion 14. On the sheet receiving tray 11, sheets P are stacked. The primary sheet-feed portion 12 transfers only the sheet P on the uppermost position from the sheet...

second embodiment

[0176]In the first embodiment, the inkjet printer 1 which calculates the influence E on the basis of the obtained gap influence Eg, temperature influence Et, and image position influence E1 is explained as an example.

[0177]In this embodiment, moreover, the inkjet printer 1 which calculates the influence E on the basis of an applicable image influence will be described as an example.

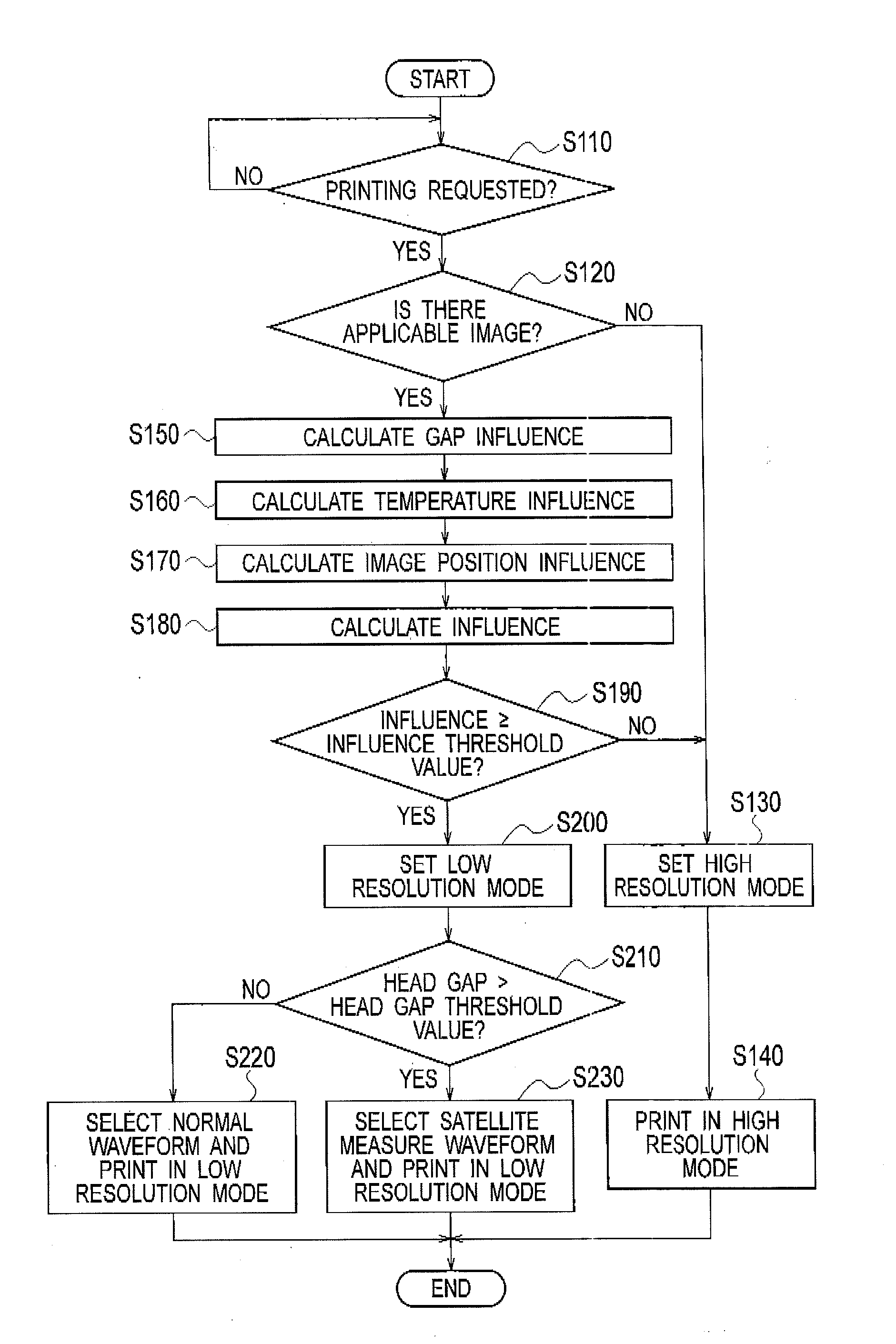

[0178]FIG. 12 is a flowchart illustrating a processing procedure of the inkjet printer 1. In processing steps illustrated in the flowchart illustrated in FIG. 12, the same processing steps as those in the flowchart illustrated in FIG. 6 are given the same step numbers and the explanation will be omitted, and only the processing steps specific to this embodiment will be explained.

[0179]As illustrated in FIG. 12, the influence calculation portion 81a calculates the temperature influence Et (S160) and then, calculates an applicable image influence Ep (S310).

[0180]FIG. 13A is a diagram illustrating an example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com