Imprinted micro-louver structure

a micro-louver and imprinting technology, applied in the field of micro-louver structures, can solve the problems of difficult to make large micro-louver sheets, difficult to achieve large-scale micro-louver sheets, and limited methods in the depth they can achieve, etc., to achieve the effect of improving transparency, reducing viewing angle, weight, thickness and cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

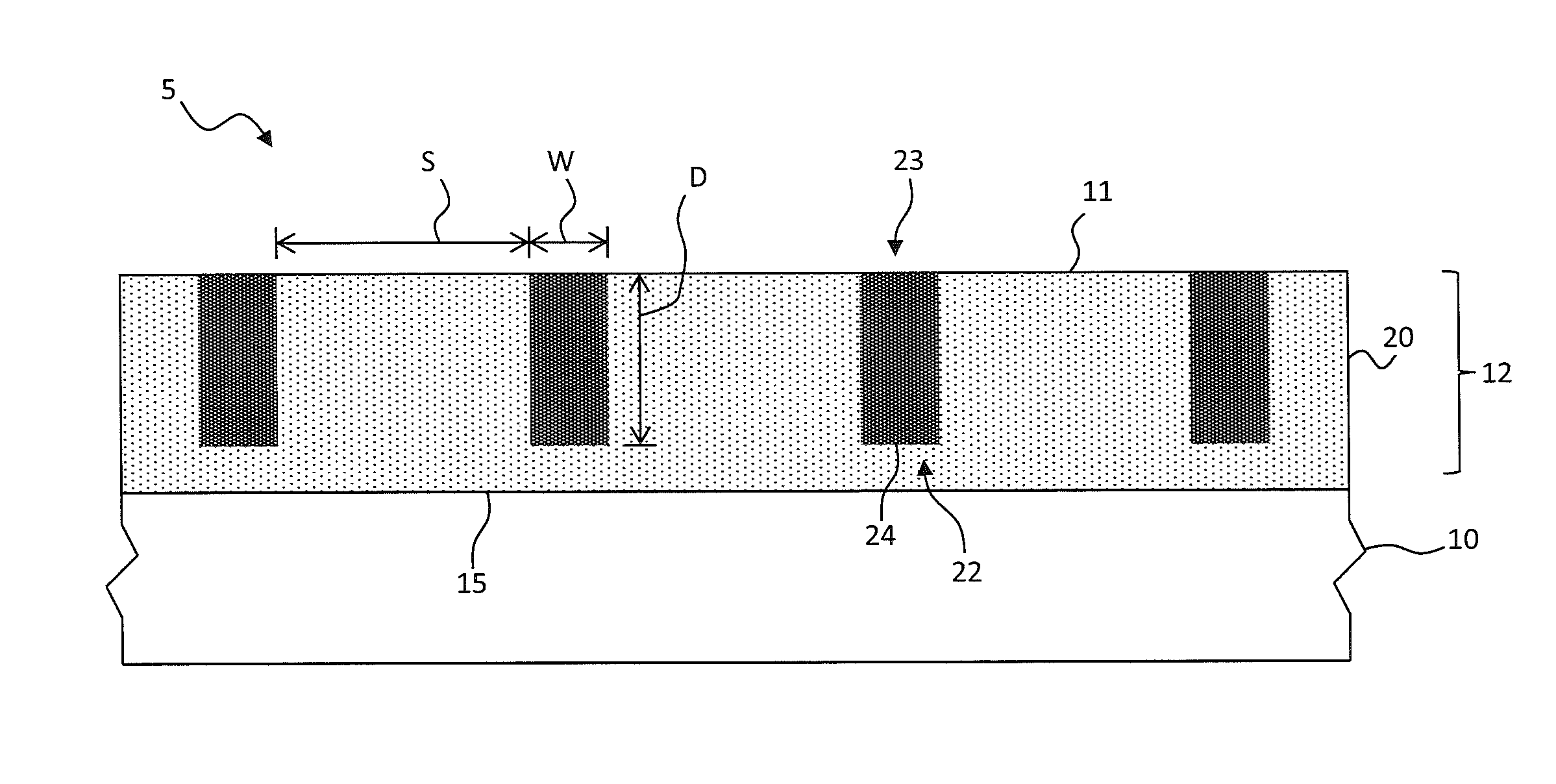

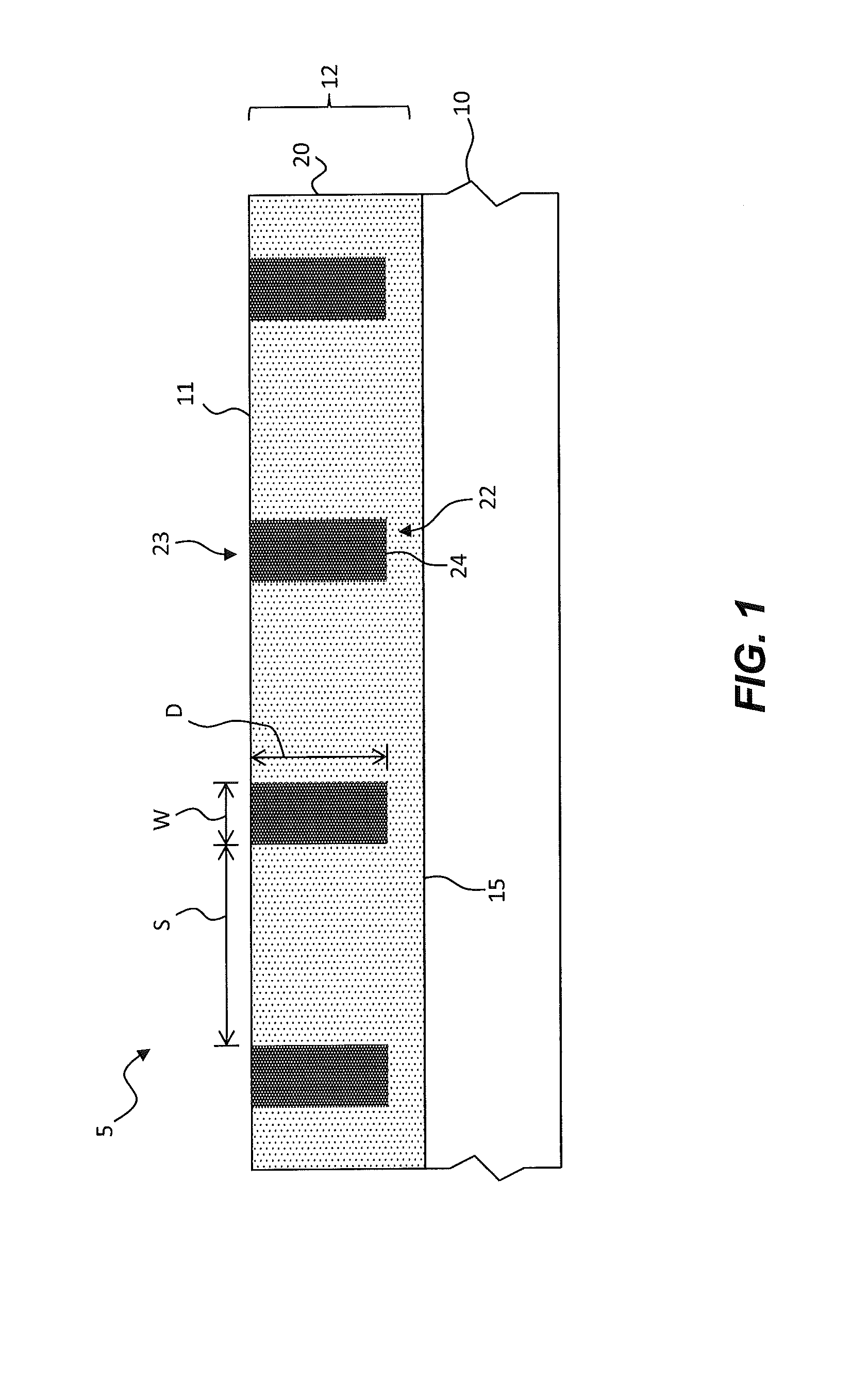

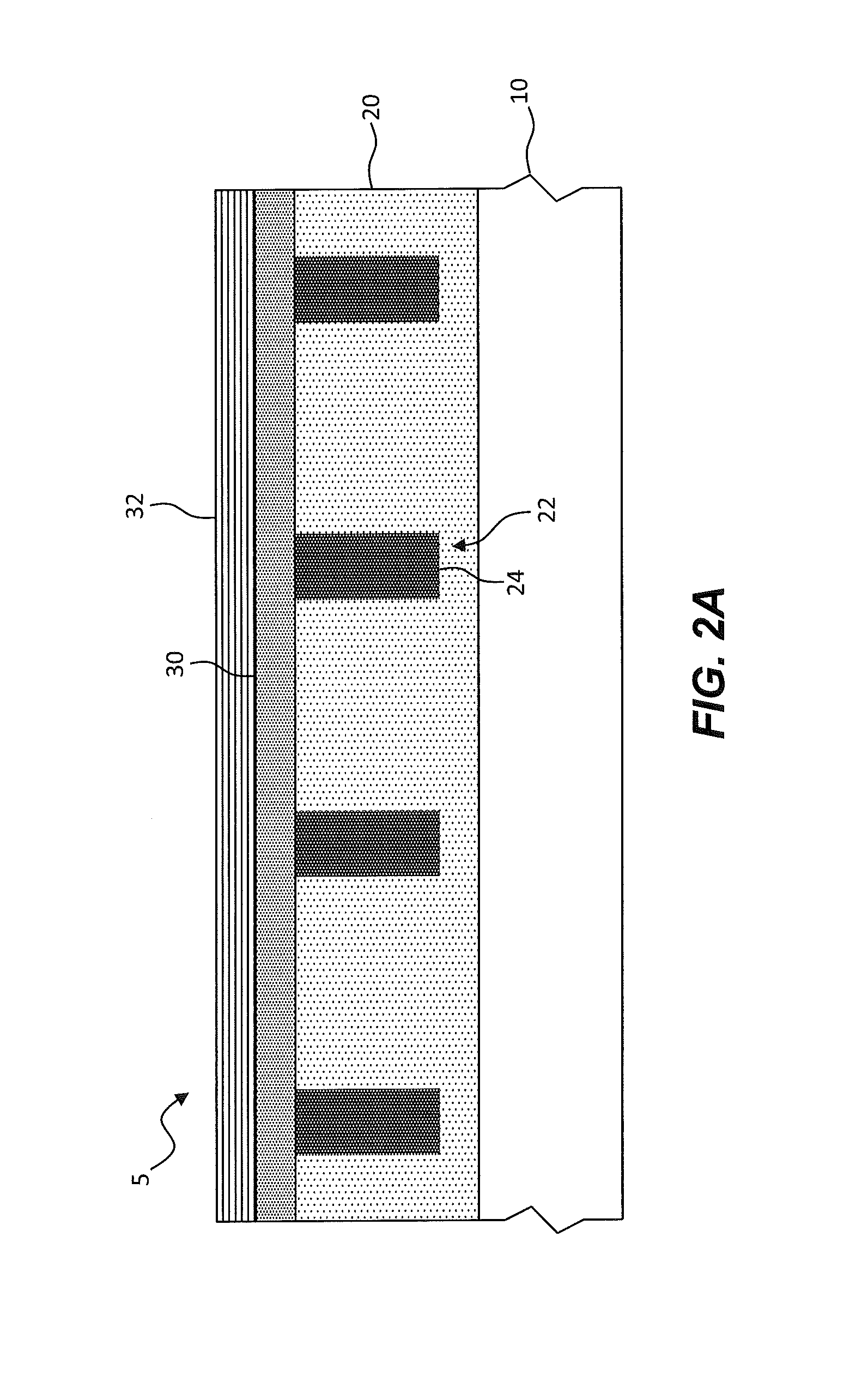

[0029]The present invention is directed to micro-louvers formed in sheets. In an embodiment of the present invention illustrated in FIG. 1, a micro-louver structure 5 includes a cured layer 20 on a surface 15, for example the surface 15 of a substrate 10. The cured layer 20 has a plurality of imprinted micro-channels 22 forming a pattern in the cured layer 20. The imprinted micro-channels 22 have a greater depth D than a width W and are spaced apart by a separation distance S greater than the width W of the imprinted micro-channel 22. A cured light-absorbing material 24 is located in the imprinted micro-channels 22. The cured light-absorbing material 24 in the imprinted micro-channels 22 form micro-louvers 23 in the micro-louver sheet 12 including the cured layer 20.

[0030]In an embodiment, the cured layer 20 is formed on the surface 15 of the substrate 10. In another embodiment, the imprinted micro-channels 22 and the cured light-absorbing material 24 extend only partially through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com