Inkjet image forming apparatus

a technology of inkjet image and forming apparatus, which is applied in the direction of electrical apparatus, printing, pictoral communication, etc., can solve the problems of insufficient density adjustment for low and high density levels, and achieve the reduction of density difference between ink heads, density difference, and density difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

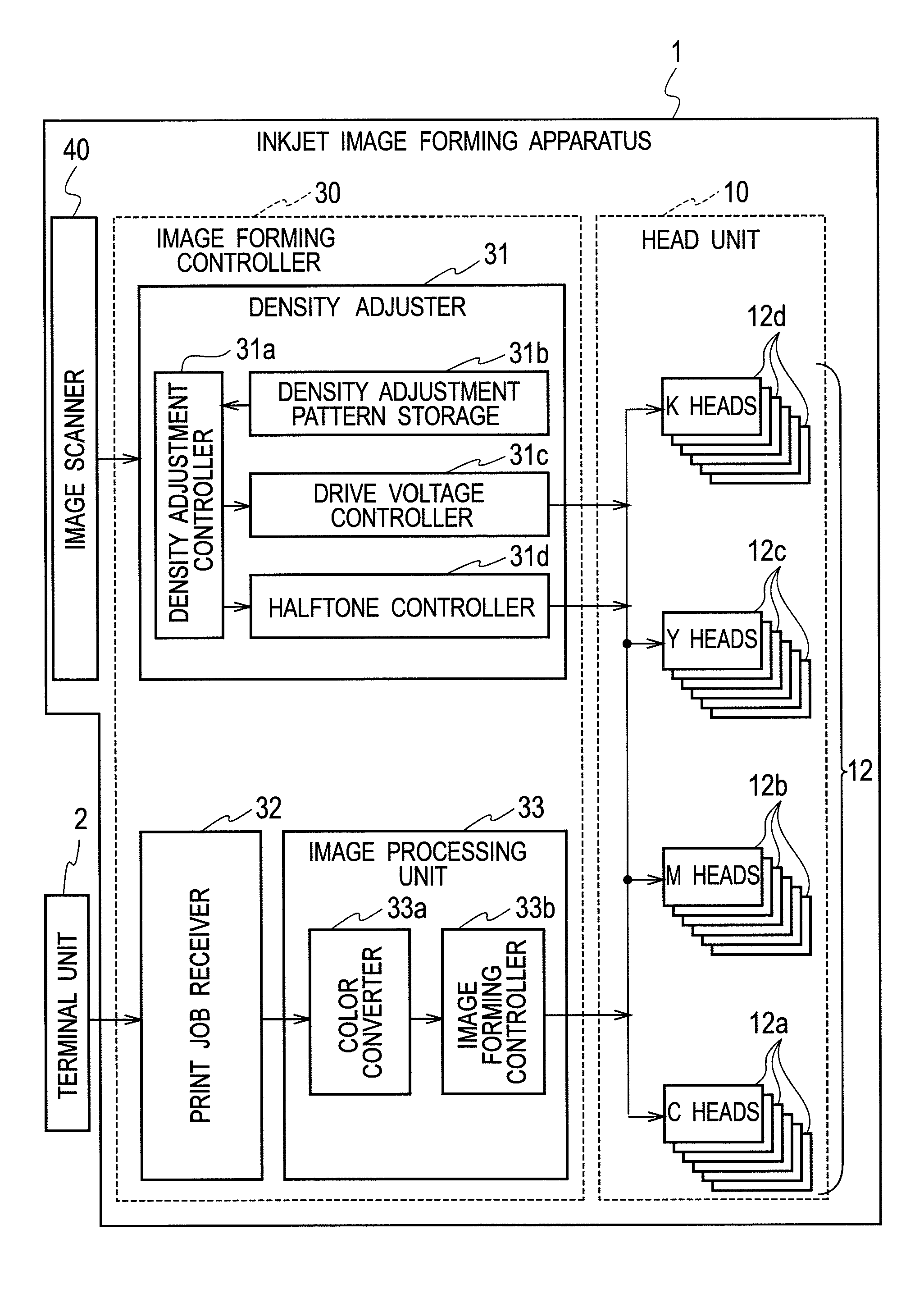

[0025]Hereinafter, an inkjet image forming apparatus 1 according to an embodiment will be explained with reference to the drawings.

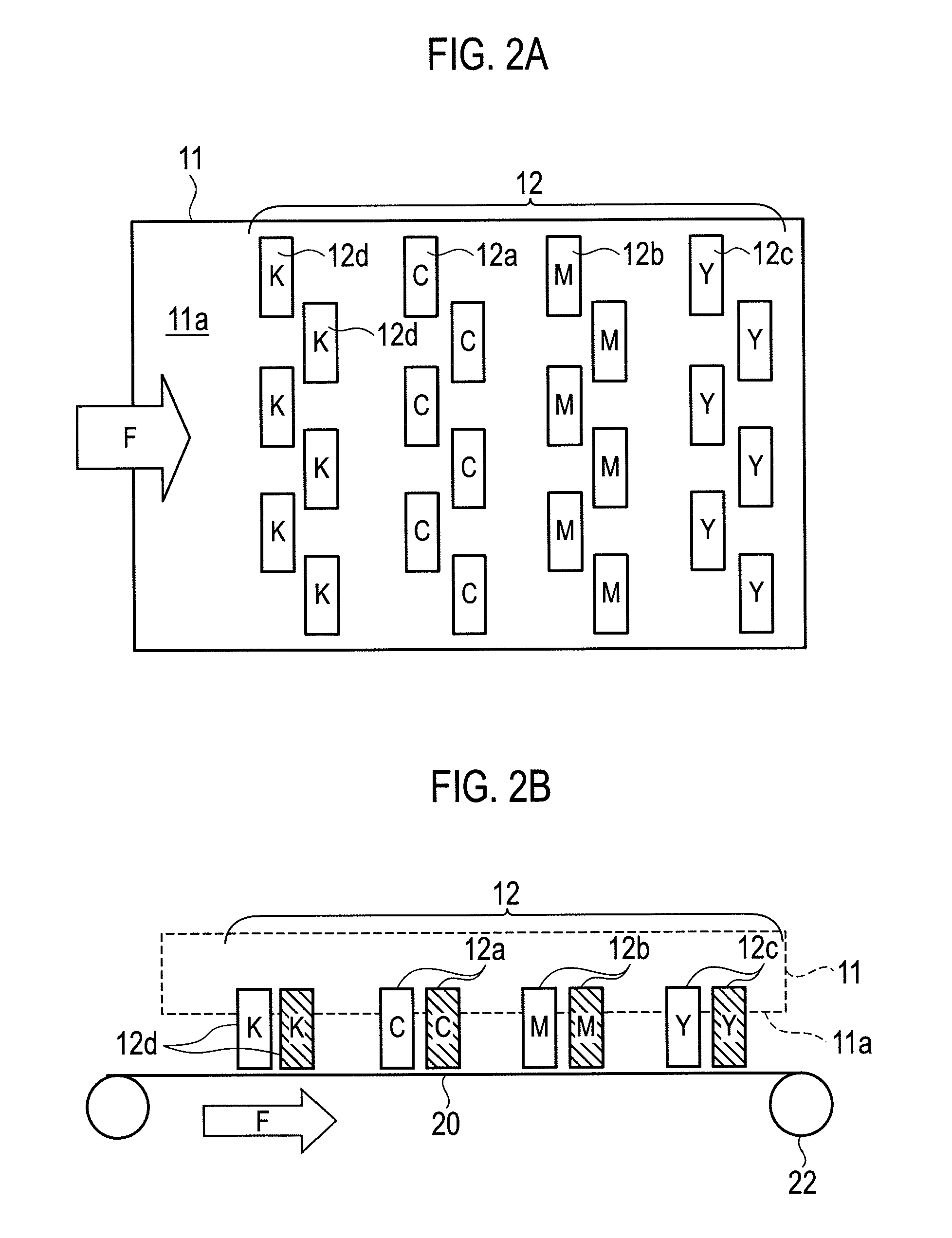

[0026]The inkjet image forming apparatus 1 is an inkjet type line color printer by which printing is done per line by injecting ink droplets from nozzles of ink heads 12 provided on a head unit 10 served as an image forming unit. In addition, each of the ink heads 12 is a multi-drop type ink head that injects ink droplets sequentially from its single nozzle onto a single dot. A density level of the single dot can be changed according to the number of ink droplets (an amount of ink droplets) injected from the single nozzle onto the single dot.

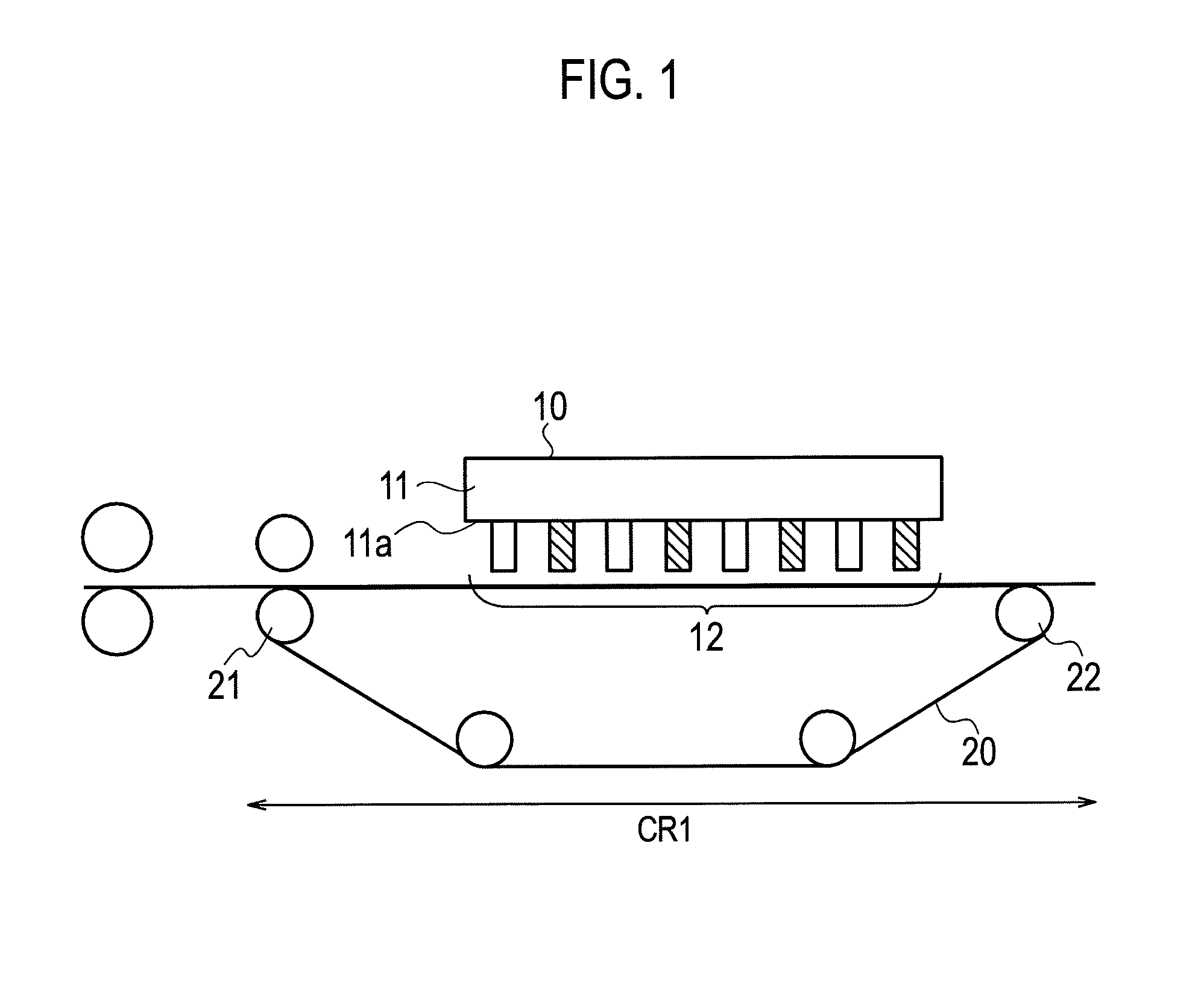

[0027]As shown in FIG. 1, the inkjet image forming apparatus 1 includes an image forming path CR1 served as its feed path. Along the image forming path CR1, print sheet P are fed by a platen belt 20 with a feed speed preset according to a print setting. The head unit 10 is provided above the image forming path CR1 so...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap