Zipper Slide for Double-Layer Nylon Zipper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

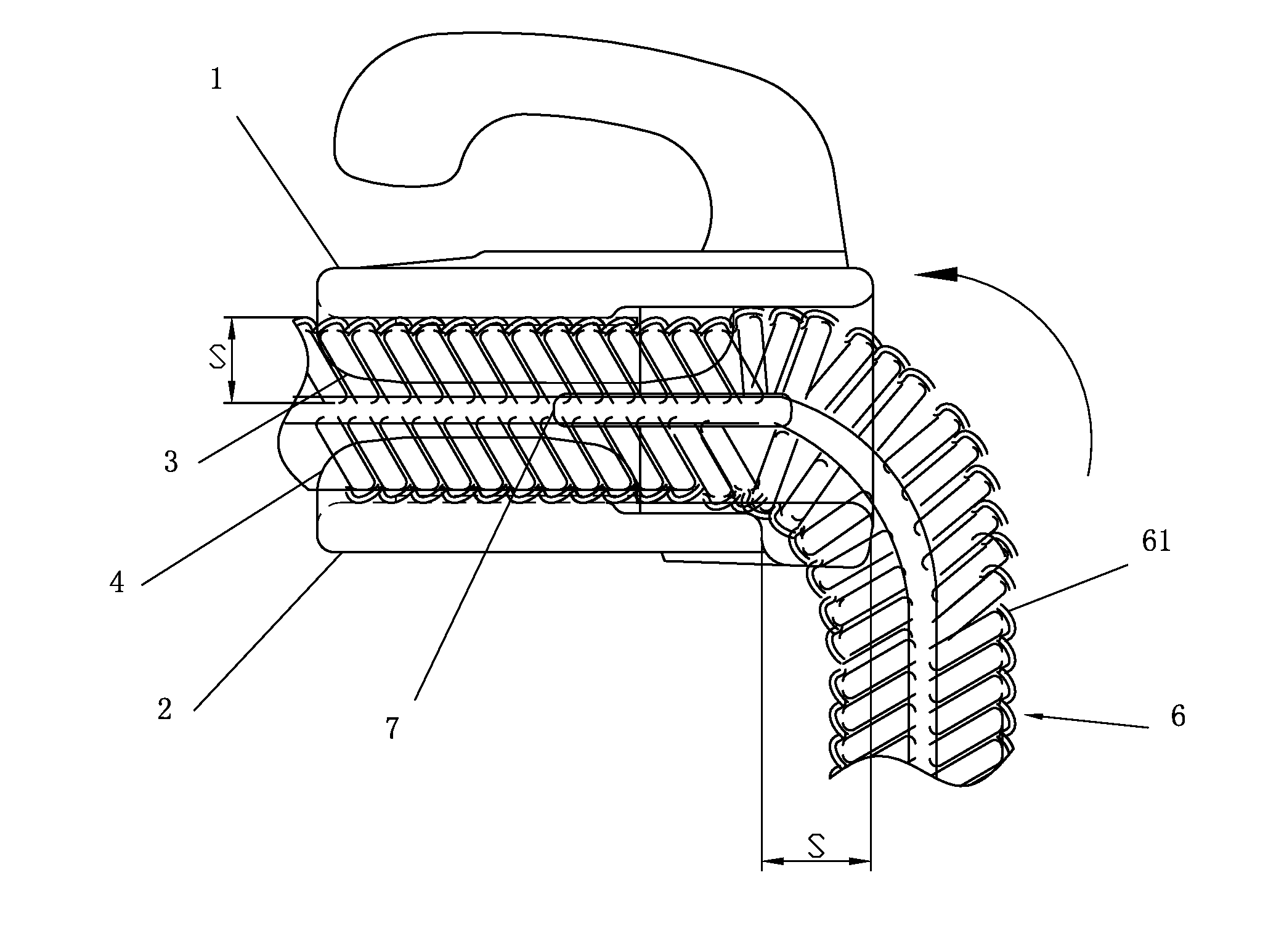

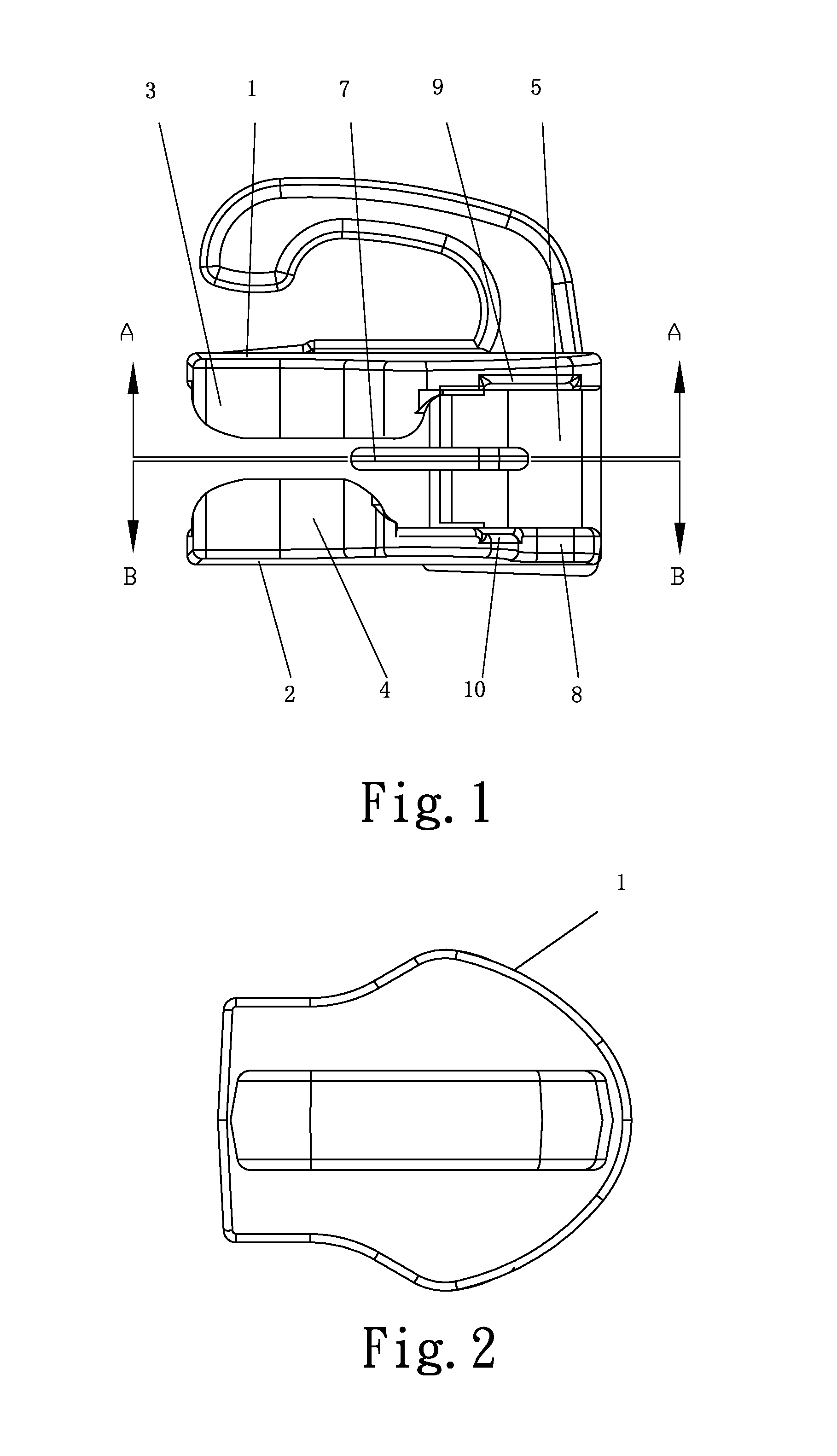

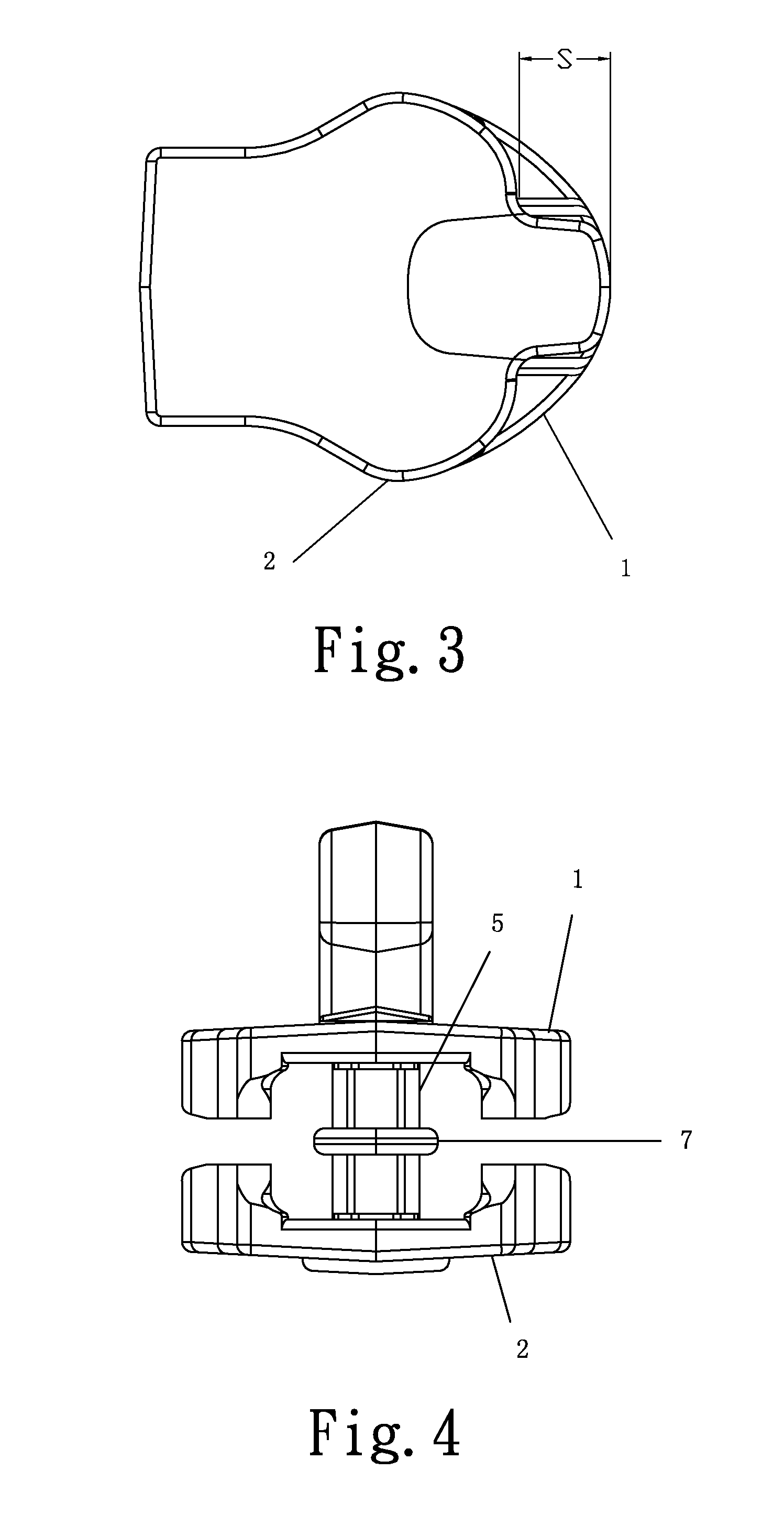

[0020]Referring to FIGS. 1-9, a zipper slide 60 for double-layer nylon zipper in accordance with the present invention is shown. As illustrated, the zipper slide 60 comprises a top slide body block 1, a bottom slide body block 2, two upper guard flanges 3 respectively downwardly extended from two opposite lateral sides of the top slide body block 1, two lower guard flanges 4 respectively upwardly extended from two opposite lateral sides of the bottom slide body block 2, a center block 5 connected between the top slide body block 1 and the bottom slide body block 2, a tongue-shaped guide plate 7 forwardly extended from a front middle part of the center block 5 and equally spaced between the top slide body block 1 and the bottom slide body block 2 for separating the upper and lower fabric tapes of the double-layer nylon zipper 6, two upper guide grooves 9 located on a rear part of a bottom surface of the top slide body block 1 at two opposite lateral sides relative to the center block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com