Modular turbomachine inner and outer casings with multi-stage steam extraction sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

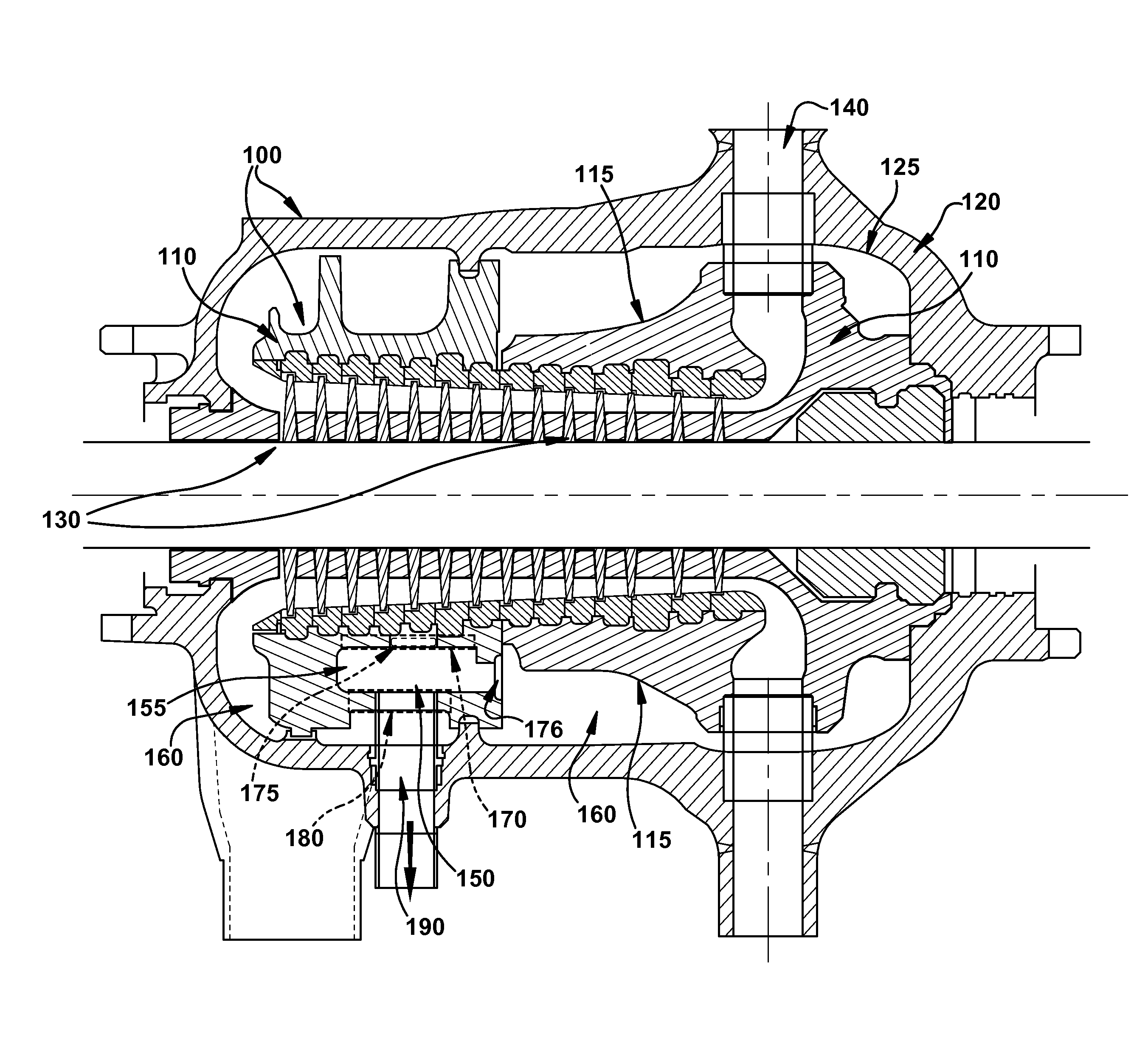

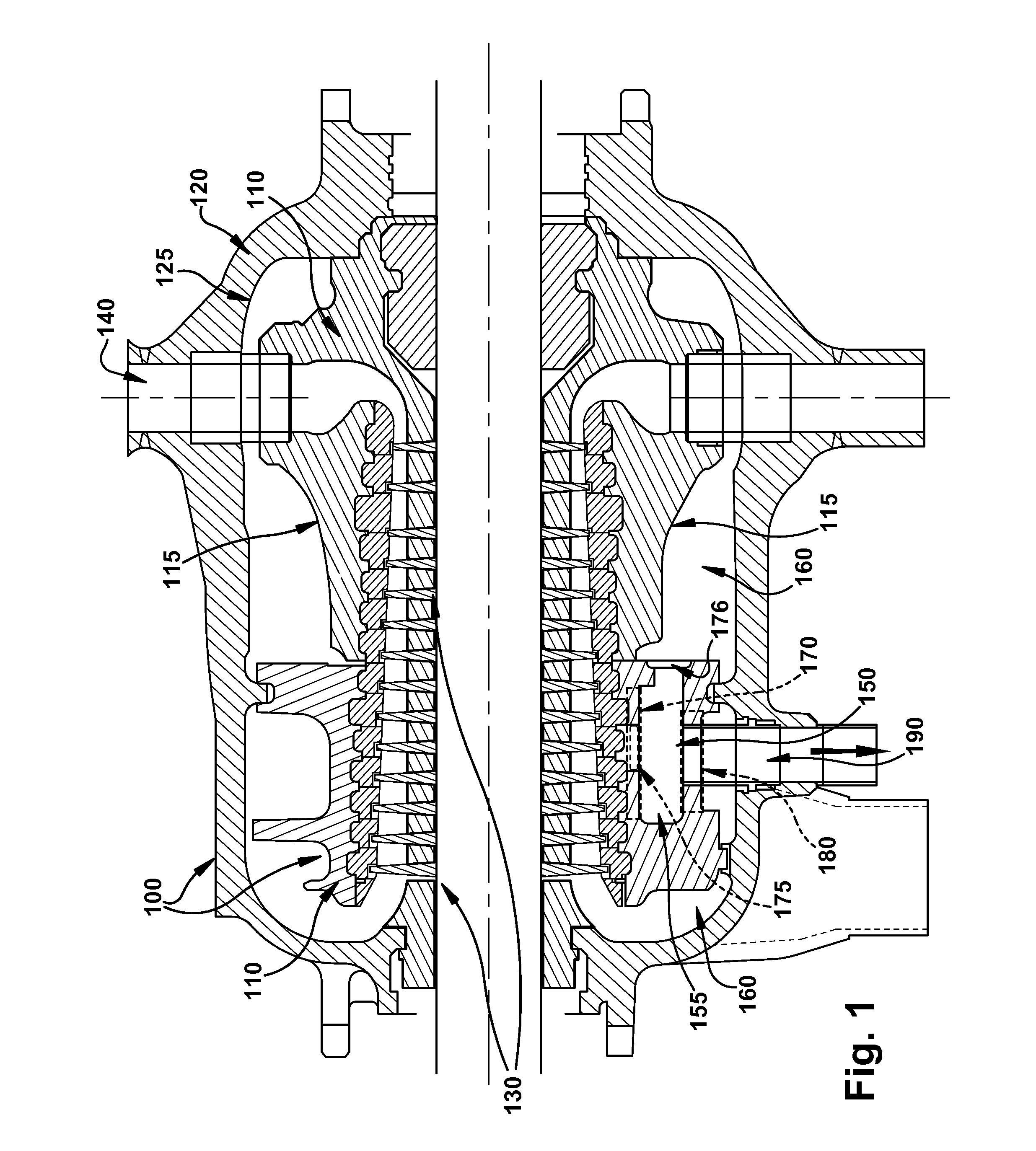

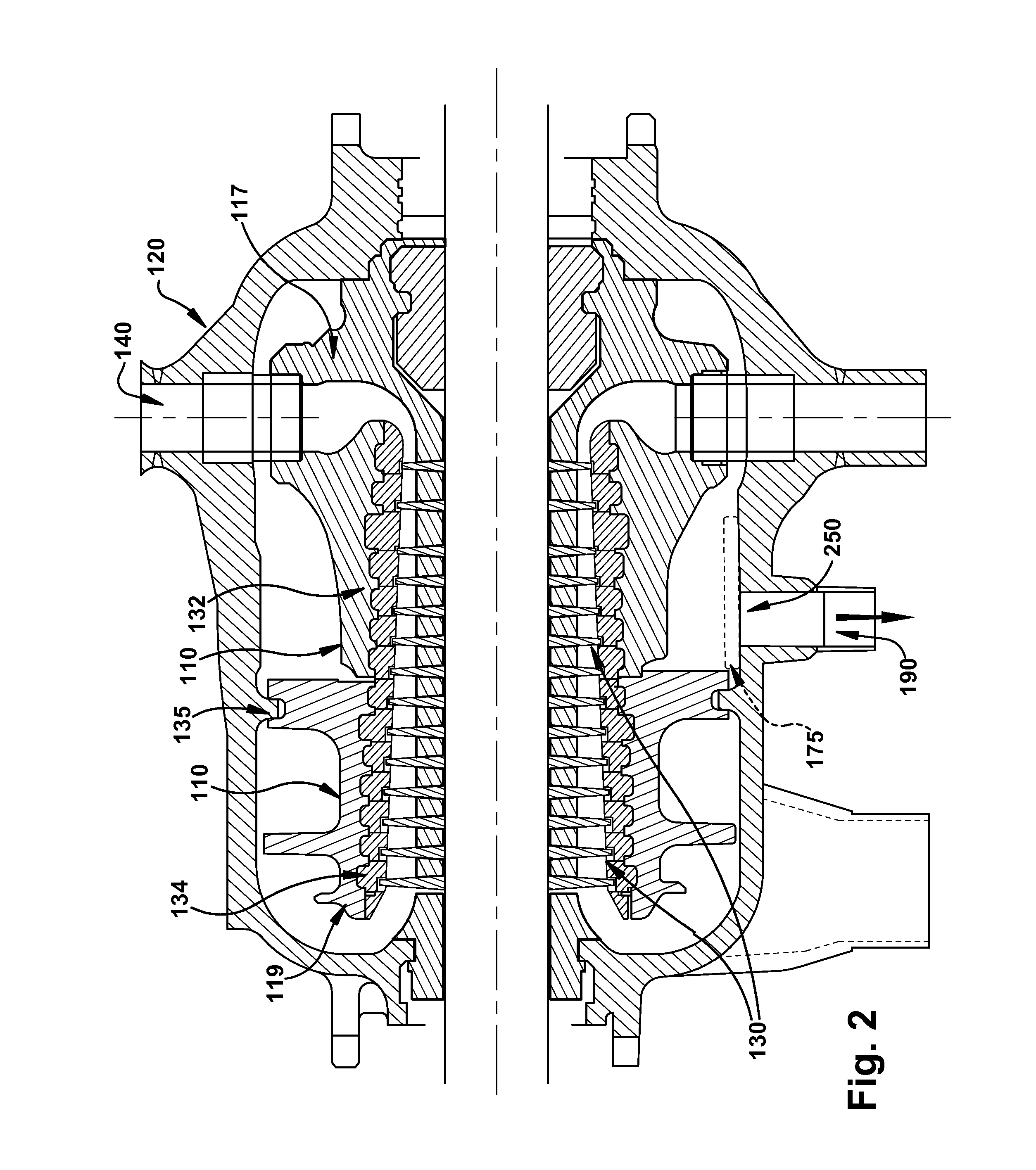

[0017]The subject matter disclosed herein relates generally to steam turbines. More specifically, the disclosure provided herein relates to inner and outer casings within steam turbines.

[0018]As indicated herein, illustrative embodiments of turbomachine casing intermediate structures and methods of their manufacture are disclosed. Embodiments described herein include turbomachine intermediate structures having many different possible fluid extraction locations which may be selected to be machined after desired characteristics of extractable fluid are known. Intermediate structures may be produced in order to be adapted at a later date. That is a casing intermediate structure may be produced with a plurality of locations for potential steam extraction, however none of such steam extraction locations are machined to define fluid extraction ports or openings in an intermediate structure. Intermediate structures are useful because a single, modular design may be modified in many differe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com