Vertical assembling and disassembling mechanism for toilet seat

a toilet seat and vertical assembly technology, which is applied in the field of vertical assembly and disassembly mechanisms of toilet seats, can solve the problems of not convenient and fast disassembly of the toilet seat cover, the inability to disassemble the toilet seat cover, so as to achieve the effect of reducing the strength of the pivot of the toilet seat, facilitating the disassembly and disassembly of the toilet sea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]Embodiments of the present invention will now be described, by way of example only, with reference to the accompanying drawings.

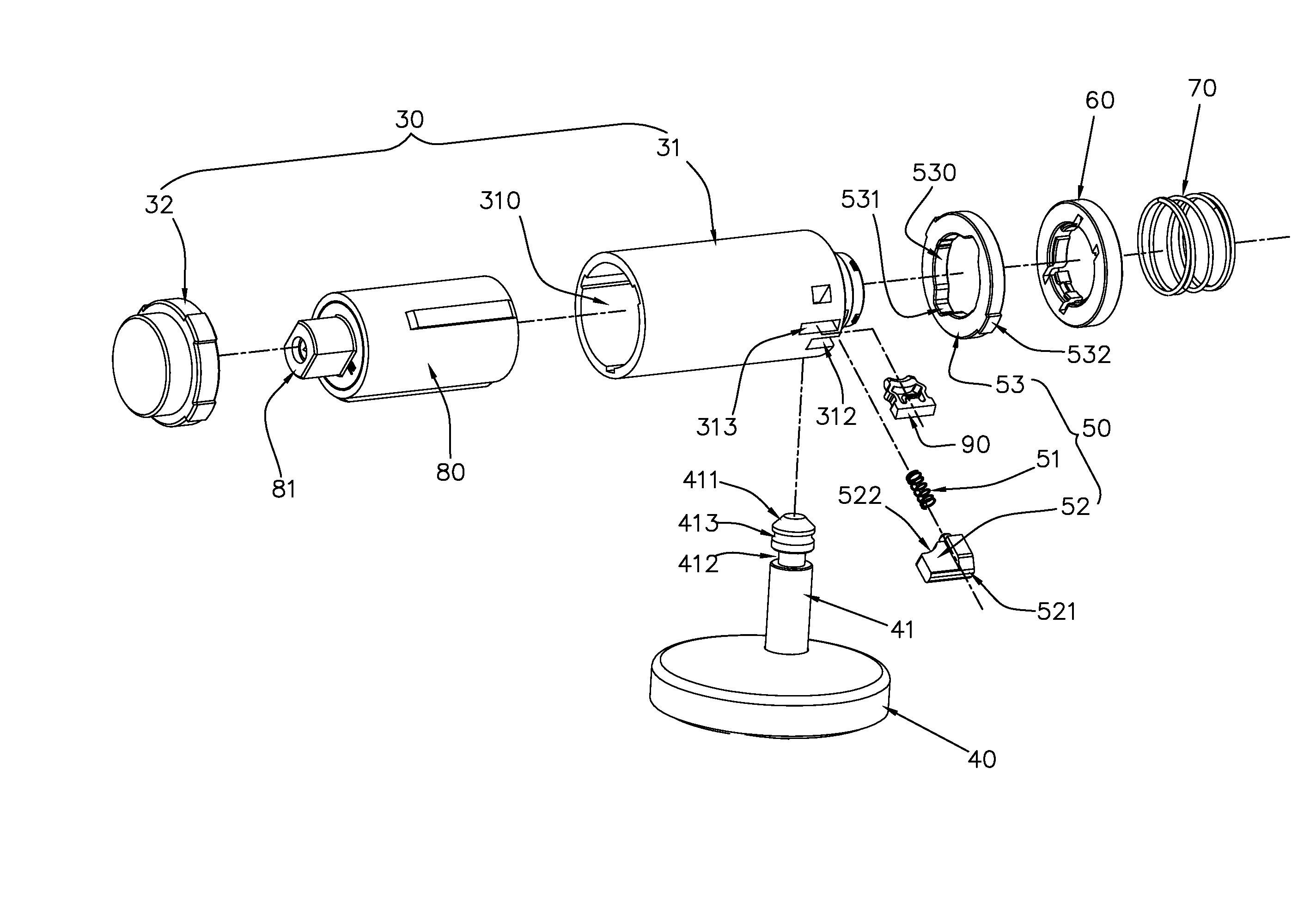

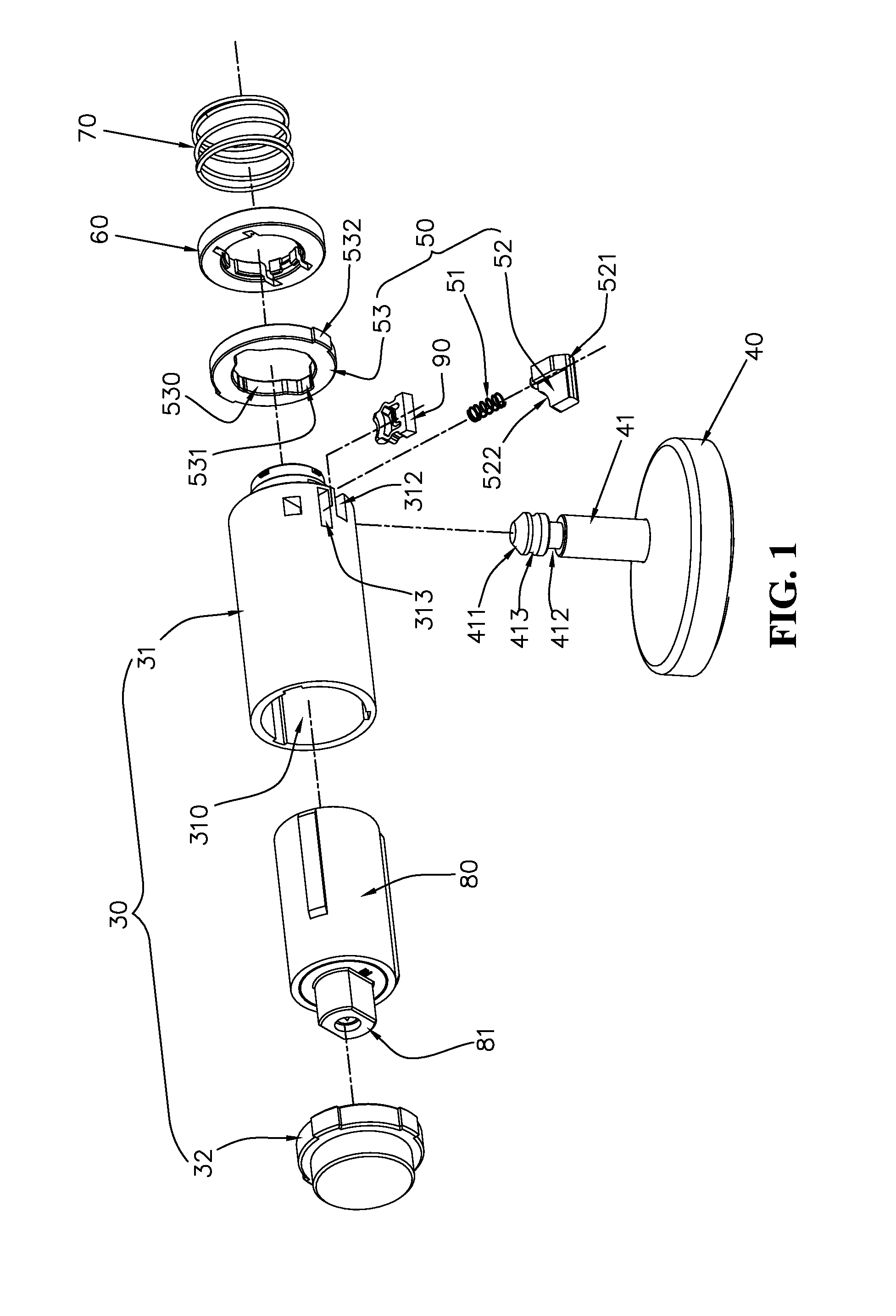

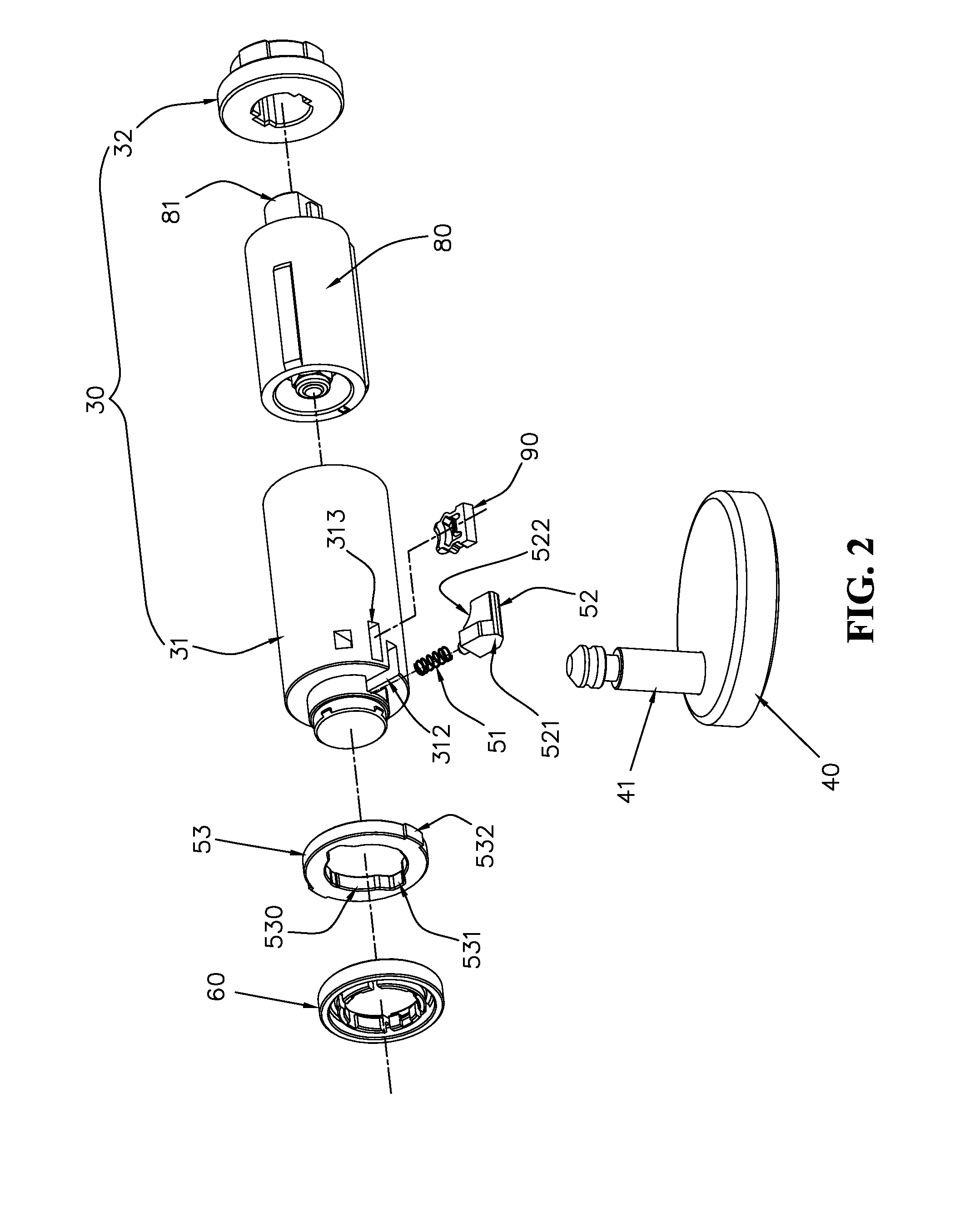

[0038]As shown in FIG. 4 and FIG. 5, the present invention discloses a vertical assembling and disassembling mechanism for a toilet seat. The present invention comprises a support 40 fixed to a toilet bowl, a fixing axle 31 for a toilet seat axle sleeve 21 to pivot on the fixing axle 31, a tuning member 32 for connecting a toilet seat cover axle sleeve 11 with a toilet seat axle sleeve 21. The fixing axle 31 and the turning member 32 from a pivot 30 for supporting the toilet seat cover axle sleeve 11 and the toilet seat axle sleeve 21 to pivot thereon. As shown in FIG. 6, a pin 41 on the support 40 is inserted into a radial pin hole 311 of the fixing axle 31.

[0039]As shown in FIG. 1 andFIG. 2, an axial inner hole 310 of the fixing axle 31 is to receive a damper 80 therein. A damper axle 81 of the damper 80 is exposed out of the axial inner hole 310 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com