Horizontal roofing roof structure

a roof structure and horizontal technology, applied in the direction of roof drainage, roofing, building components, etc., can solve the problems of increasing the number of parts, difficulty in reducing cost, and possible water barrier property problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

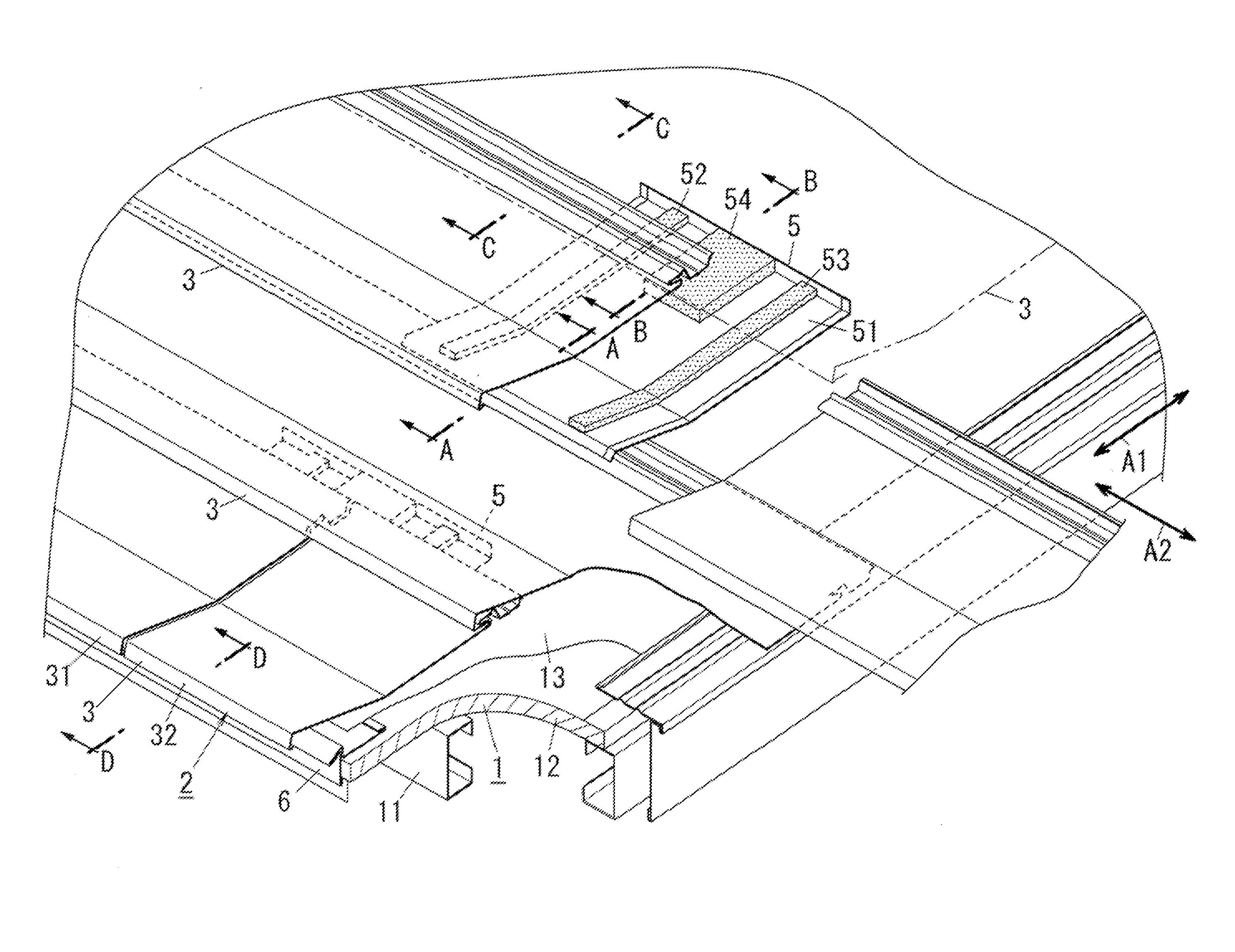

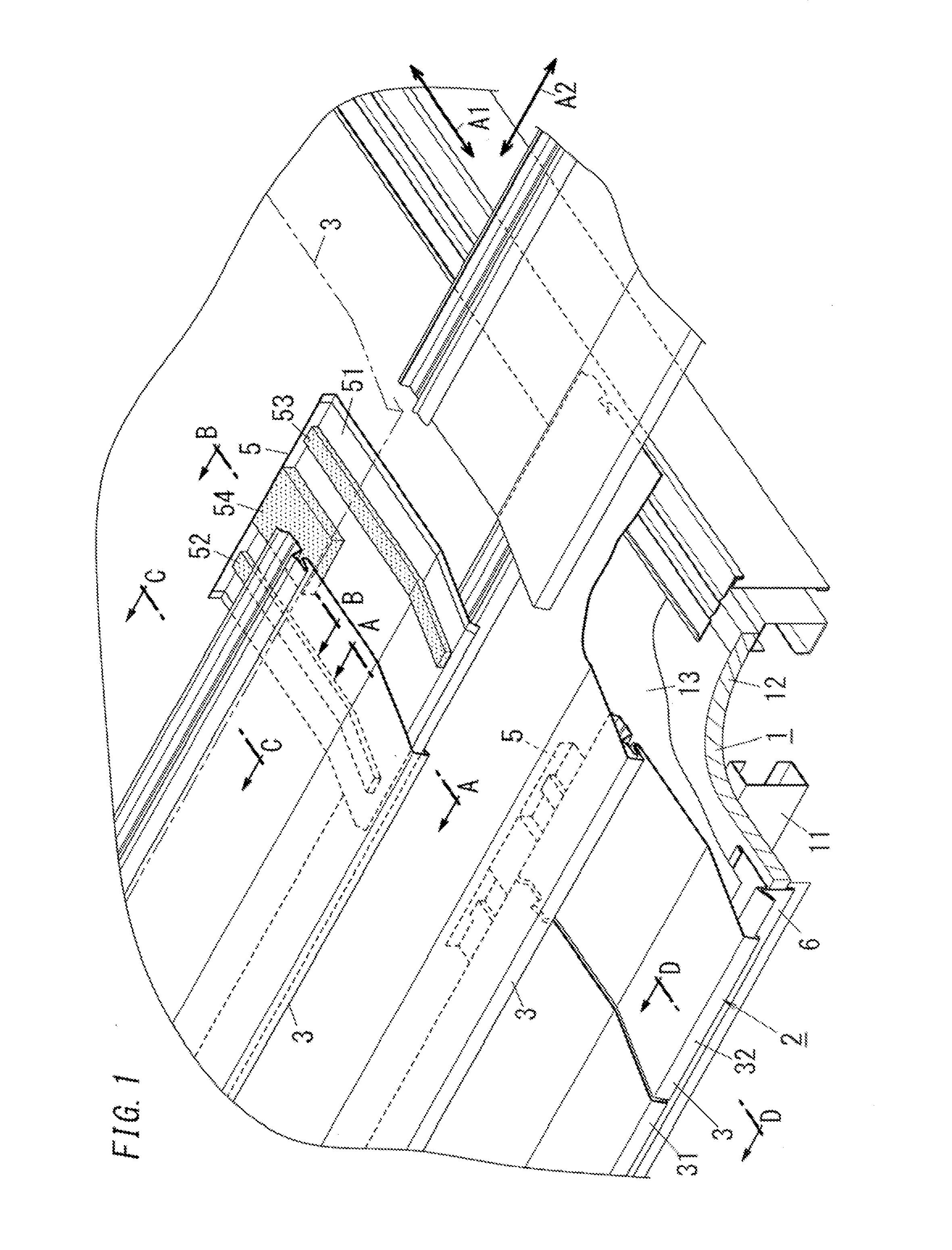

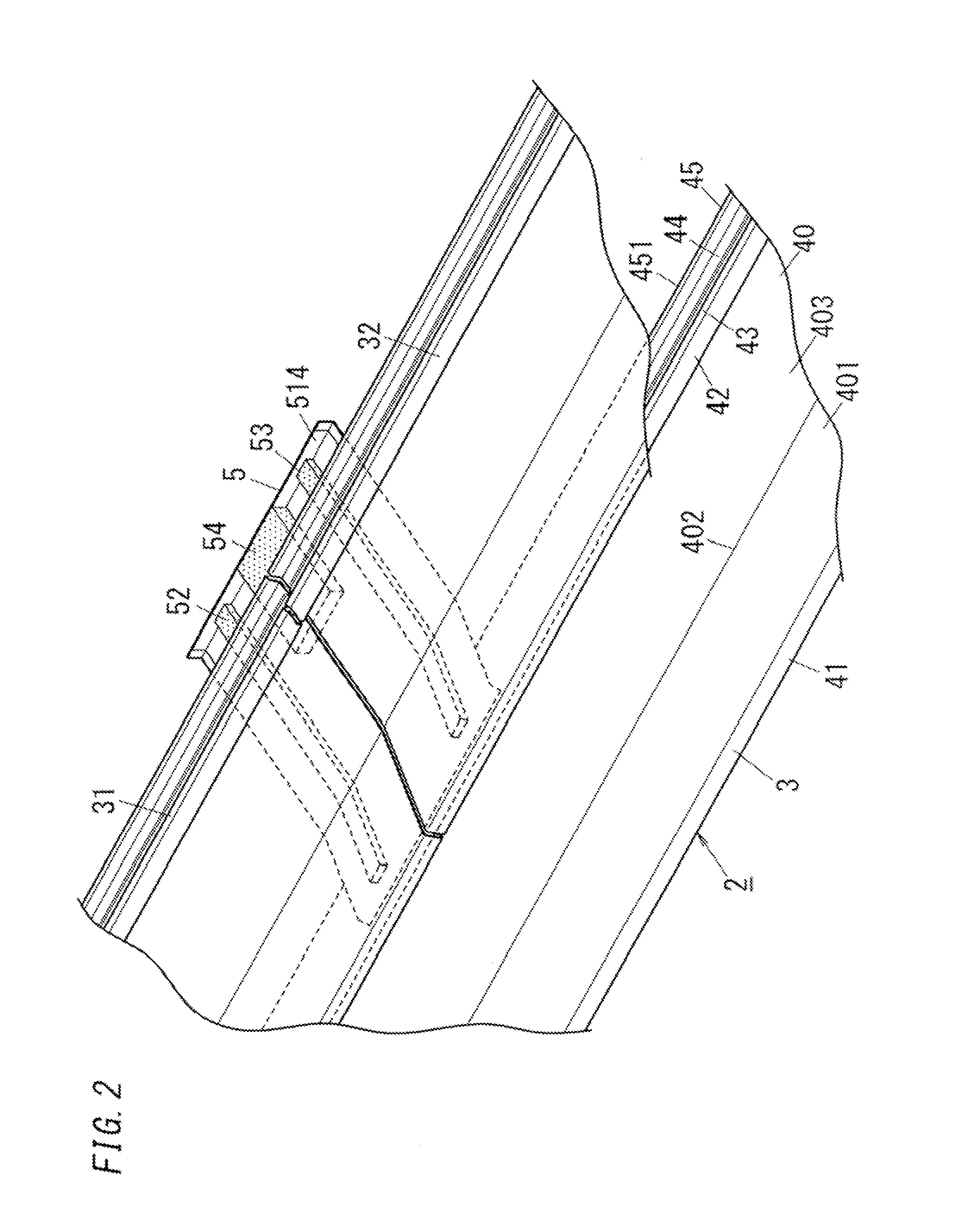

[0019]The following description is made to an embodiment according to the present invention with referring to attached drawings.

[0020]A horizontal roofing roof structure of the embodiment is for example applied to a roofing structure such as a gable roof, a hipped roof, and a penthouse roof. A roof is provided on a top part of a building. The roof is inclined. An inclining direction of the roof (a direction parallel to an arrow A1 in FIG. 1, hereinafter, referred to as a roof pitch direction) is defined as a direction parallel to an eave-ridge direction. In other words, the roof pitch direction is defined as a direction parallel to a rain flowing direction (a water-flow direction) on the roof. Also, a direction perpendicular to the roof pitch direction is defined as a lateral direction (i.e. a ridge direction, a direction parallel to an arrow A2 in FIG. 1).

[0021]In the embodiment, a “ridge” is defined as the highest part of a surface of the roof. Therefore, according to the embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com