Roof flashing for a pipe or duct

a technology for flashing and ducts, applied in the direction of roofs, building components, building insulations, etc., can solve the problems that flashing should be produced in an uncomplicated and economically efficient manner, and achieve the effect of simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

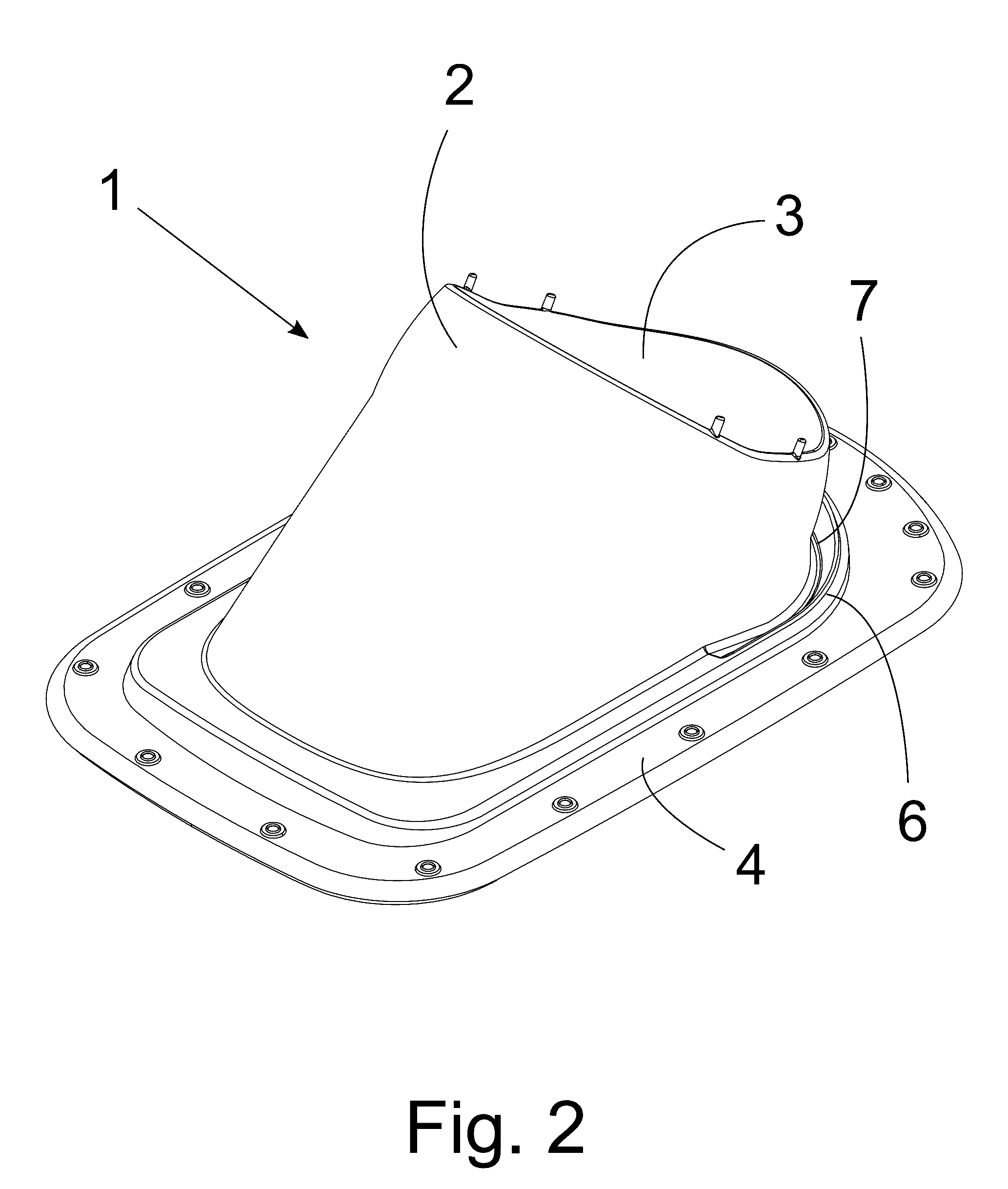

[0026]The flashing is particularly designed for a seamed roof or for a roofing element shaped as a seamed roof. The mounting of the flashing may be carried out rapidly due to the simple and compact structure. The same flashing may be used for various roofs, each having a different pitch.

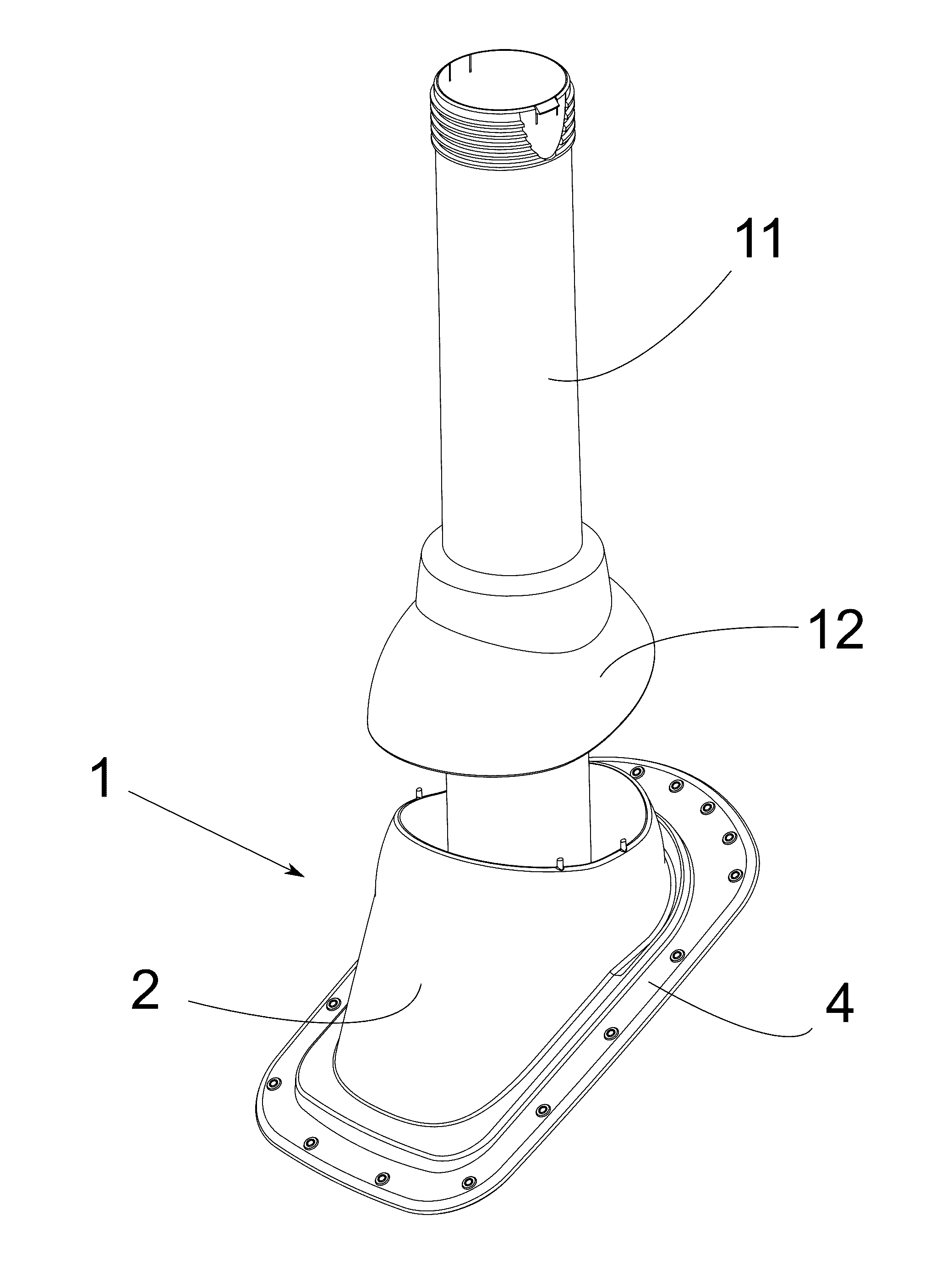

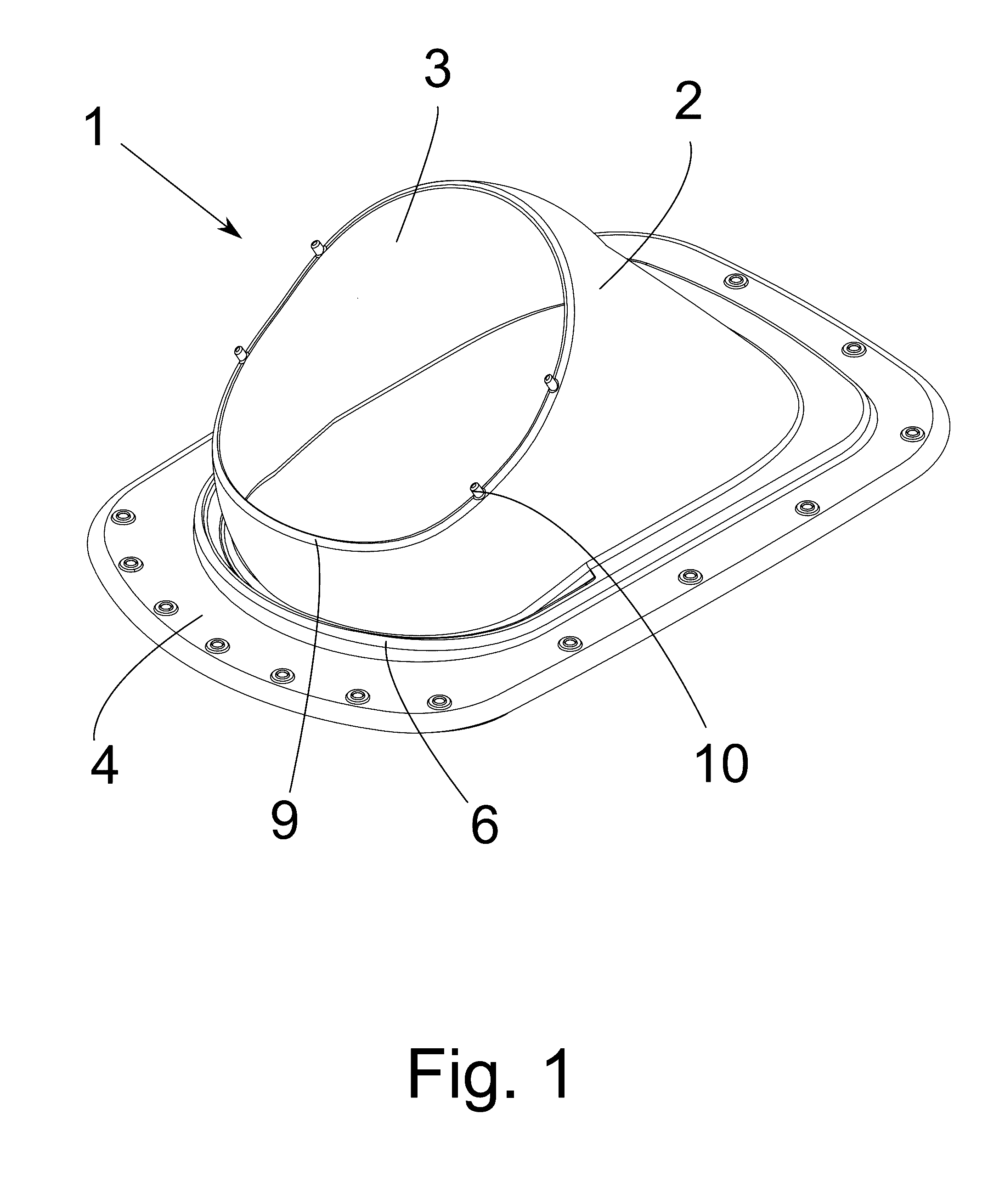

[0027]FIG. 1 shows a first perspective view of a flashing 1 according to at least some embodiment of the flashing 1 according to the present invention. The flashing 1 comprises collar 2 having an oblong opening 3 for a pipe duct (not shown), and a substantially planar flange 4. Collar 2 is thus formed, that the flashing 1 may be used for any roof pitch in the range 13° to 50°. In other words, the flashing 1 may be used for various seamed roofs having a pitch in the mentioned range, for example 35°. The oblong shape of opening 3 facilitates this. The plane defined by the upper and lower edges of opening 3 is inclined by an angle α which is in the range 25°-35° relative to the plane defined by flange 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com