Connecting ring for interior cross straps of a suitcase

a technology for connecting rings and suitcases, which is applied to snap fasteners, other accessories, and press-button fasteners, etc., can solve the problems of easy damage to bending parts, easy fracture of bending parts, and time-consuming to change between variable machining methods in a manufacturing process, so as to prevent the damage of the connecting straps of the suitcase caused by long-time use and reduce the time of a manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

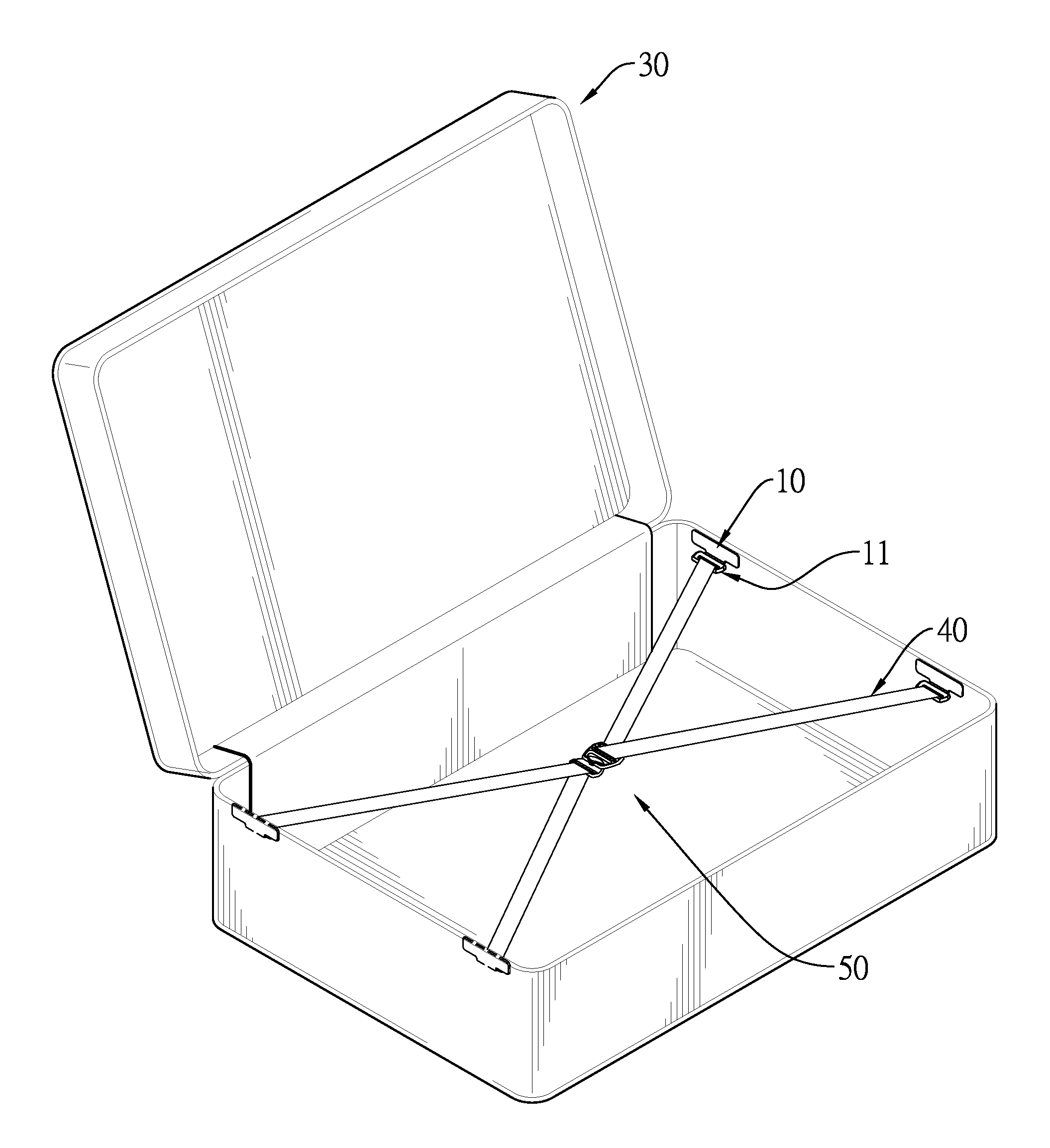

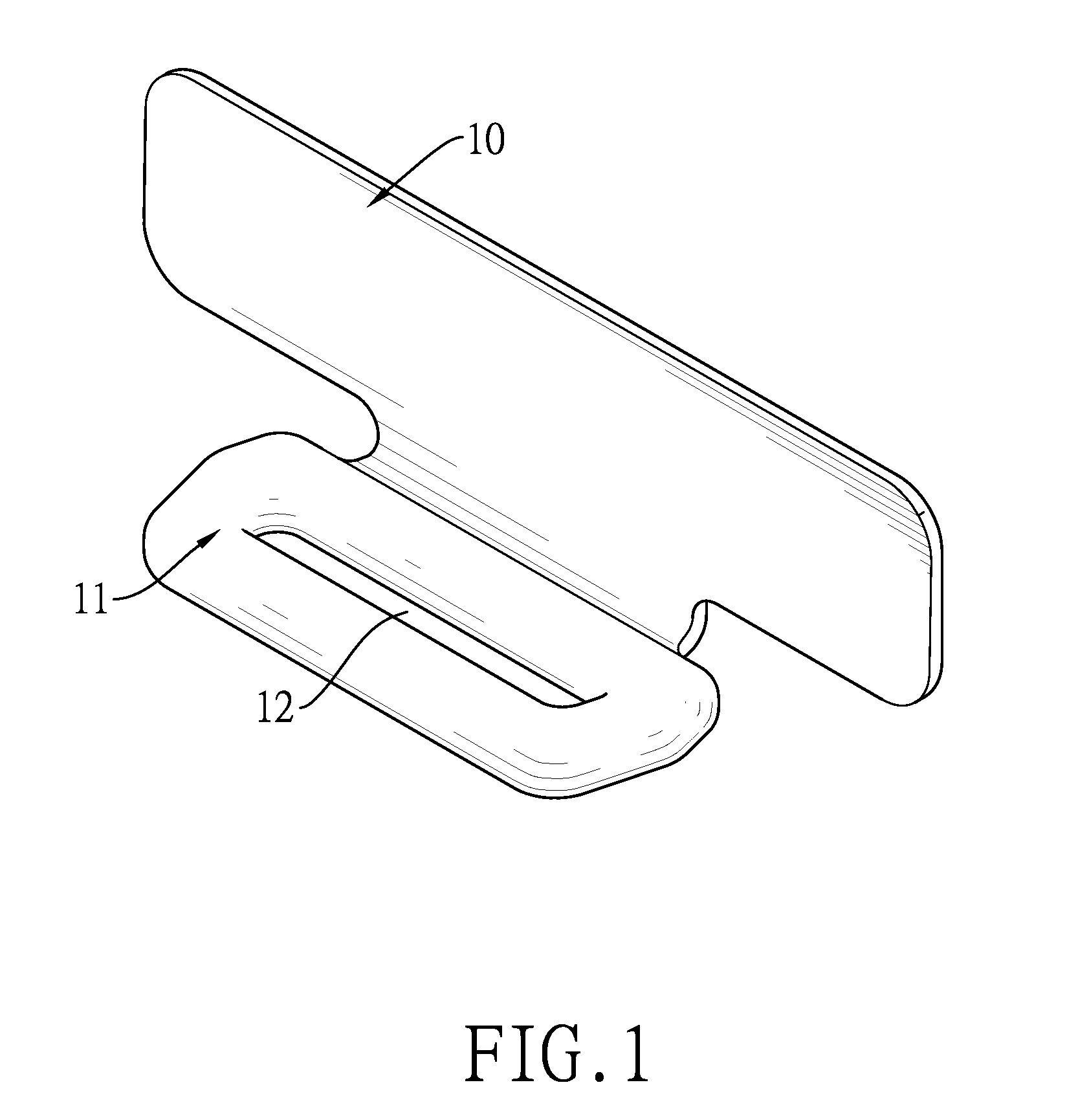

[0018]With reference to FIG. 1, a connecting ring for interior cross straps of a suitcase in accordance with the present invention comprises a sewing sheet 10 and a connecting collar 11. The sewing sheet 10 is a soft and thin sheet made of plastic. The connecting collar 11 is formed on an elongated side of the sewing sheet 10 and is perpendicular to the sewing sheet 11. A linking hole 12 is formed through the connecting collar 11.

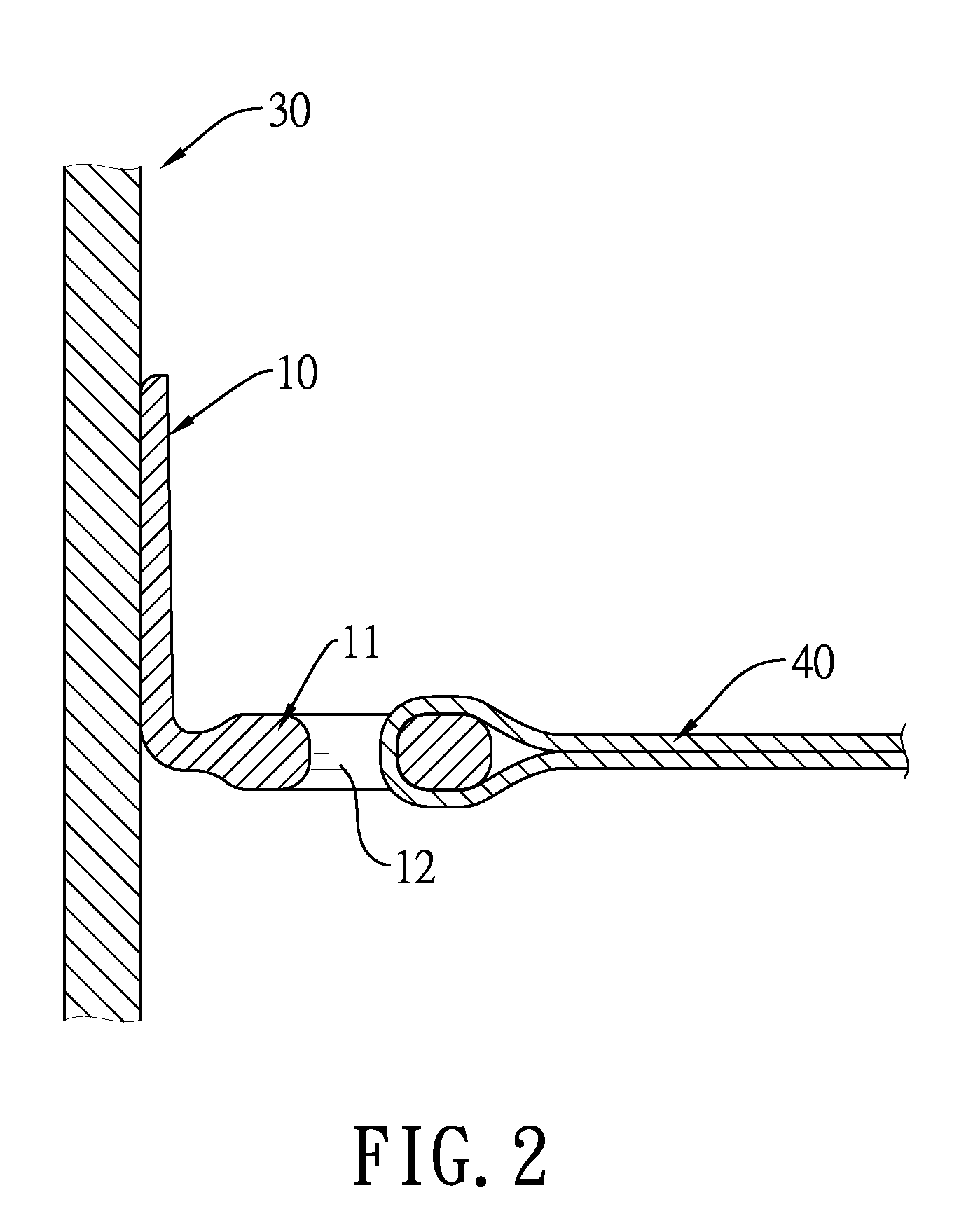

[0019]With reference to FIGS. 2 and 3, four connecting collars as described are sewed in the suitcase 30. Each connecting collar 11 is mounted near one of the four corners in the suitcase 30. Two of the connecting collars are mounted on one of the inner surfaces of the suitcase while the other two of the connecting collars are mounted on the opposite one of the inner surfaces of the suitcase. Two connecting straps 40 are respectively mounted securely between four connecting collars. Two ends of each connecting strap 40 are mounted respectively through the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com