Anti-Splash Holding Tank and Stand-Alone Anti-Splash Guard for Portable Toilets

a portable toilet and anti-splash technology, applied in the field of portable toilets and restrooms, can solve the problems of serious infections, unsanitary for users, and insufficient portability of non-flushing toilets, and achieve the effects of low material and manufacturing costs, and positive buoyancy in water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

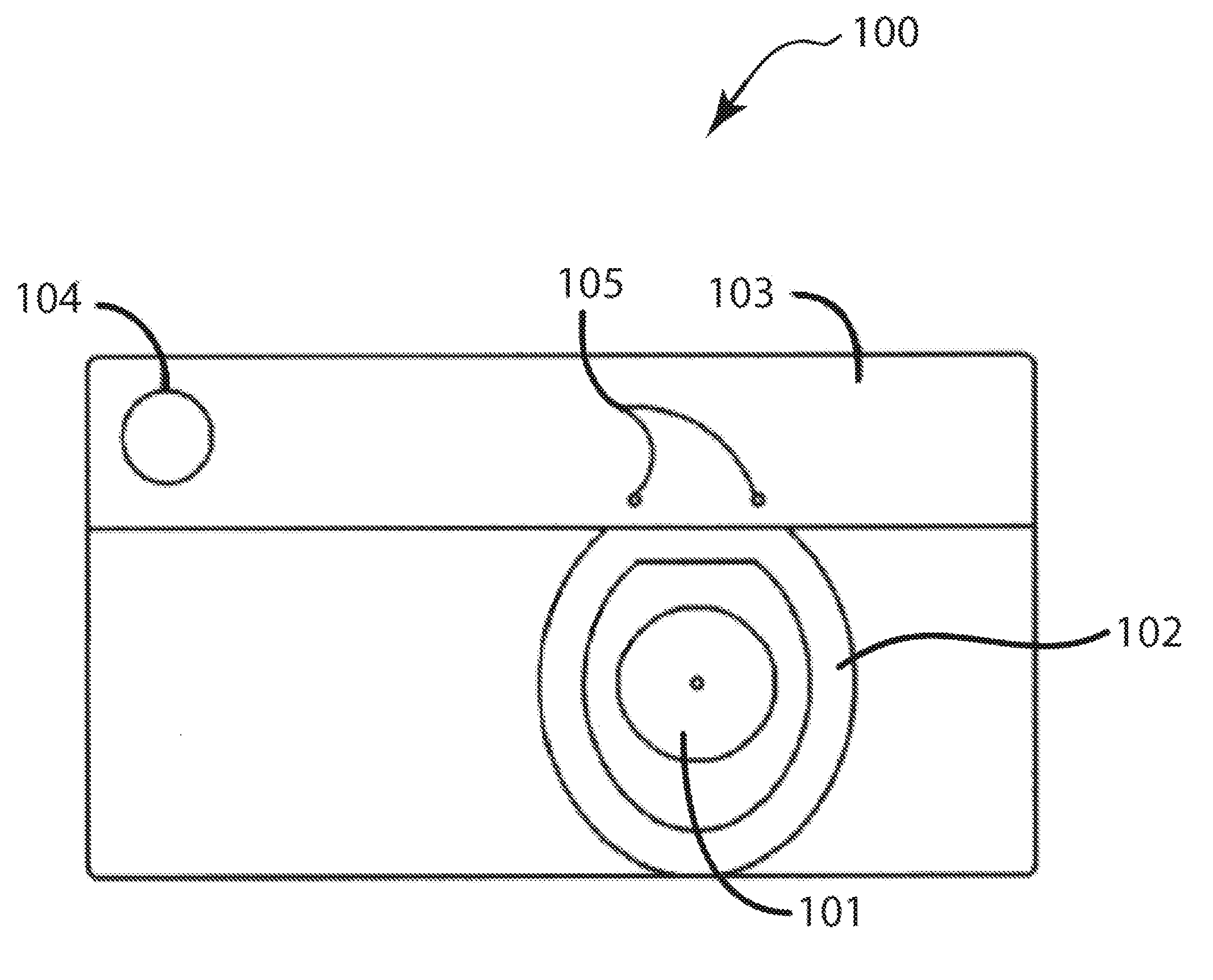

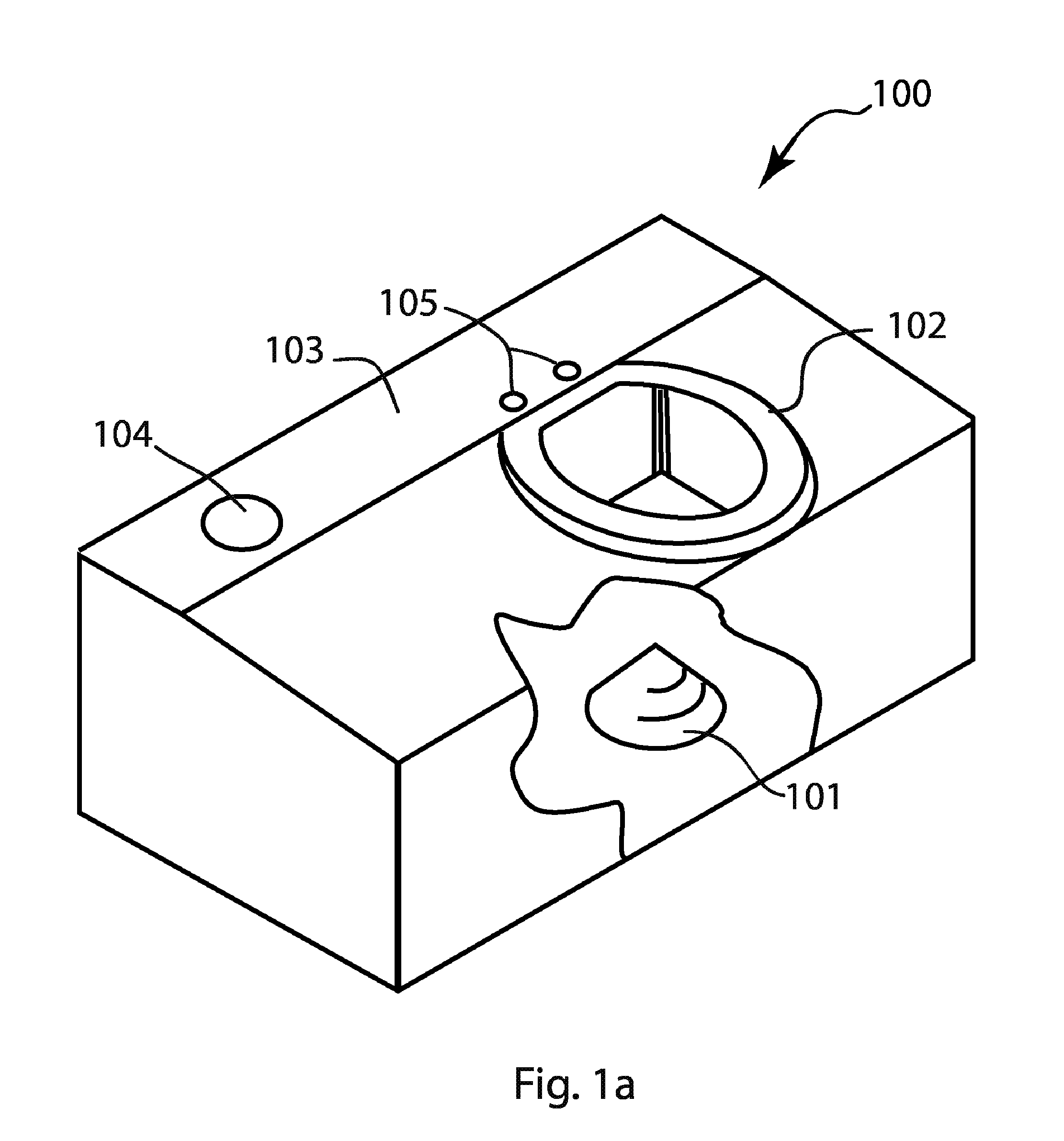

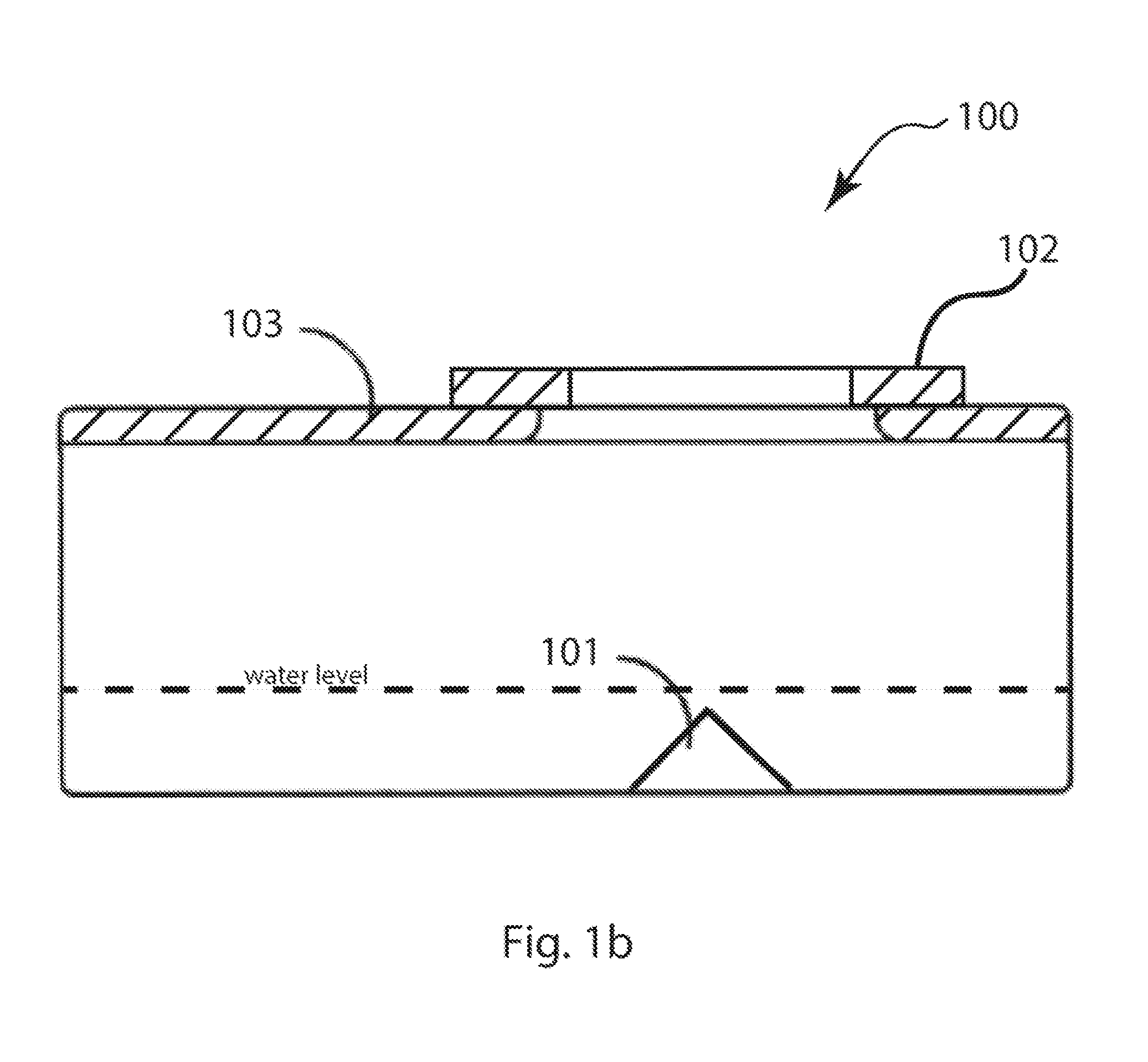

[0019]FIG. 1a shows an isometric view of the preferred embodiment of the invention, a portable toilet holding tank 100 having a tapered pillar anti-splash guard 101 having sloped sides converging to an apex, where in the embodiment shown, the tapered pillar is a cone, shown in the cut-away view rising up from the bottom of the tank directly under the seat 102 integral with tank body 103. Other conical shapes may be used as tapered pillars, where the shape may be substantially conical. In the preferred embodiment, anti-splash guard 101 projects upward from the bottom of holding tank 100, whereby the height of its apex may be a small fraction of the total height of tank 100, in order to remain submersed below the water surface. However, a taller embodiment of anti-splash guard 101 may extend above the water surface so as to expose the apex. Also shown in FIG. 1a are vent hole 104 and seat mounting holes 105. The surface of the water or portable toilet fluid, such as those commercially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com