Downhole Apparatus and Method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

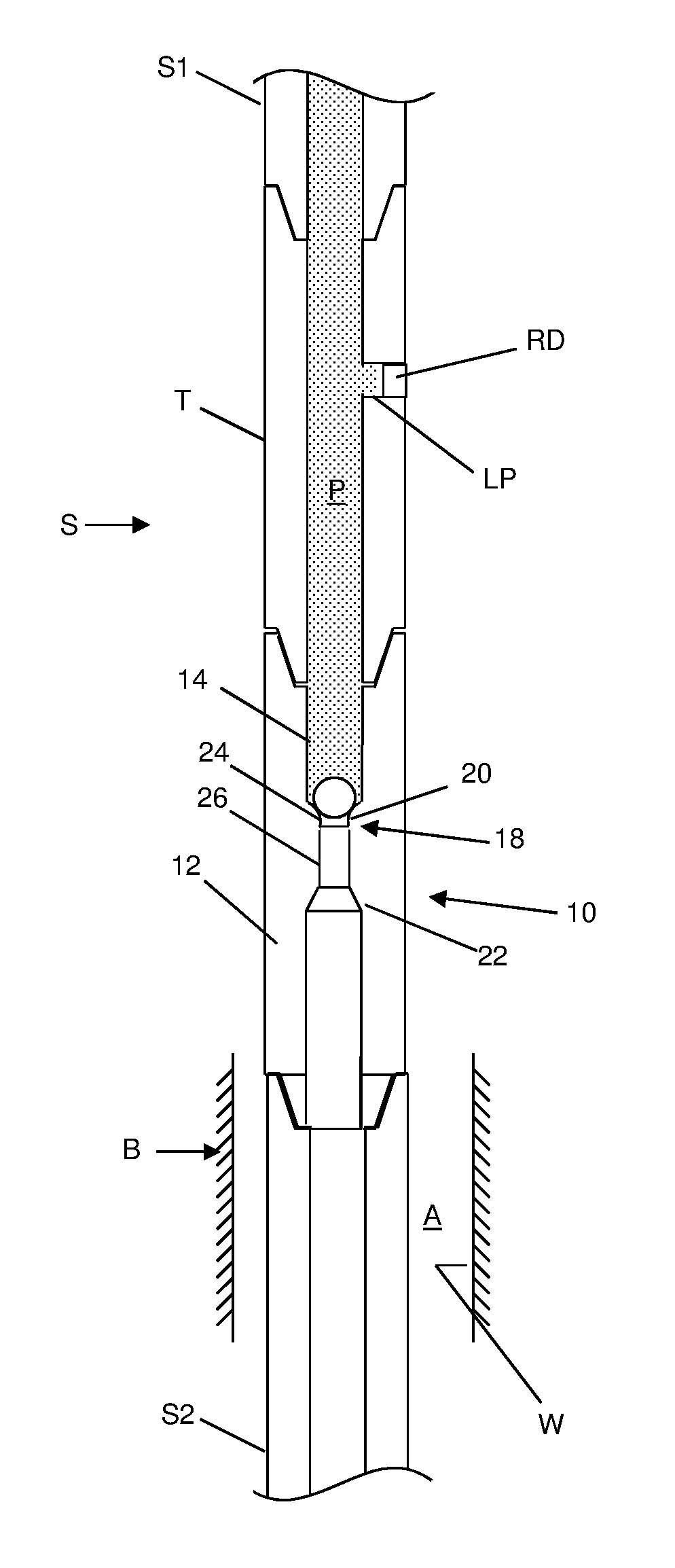

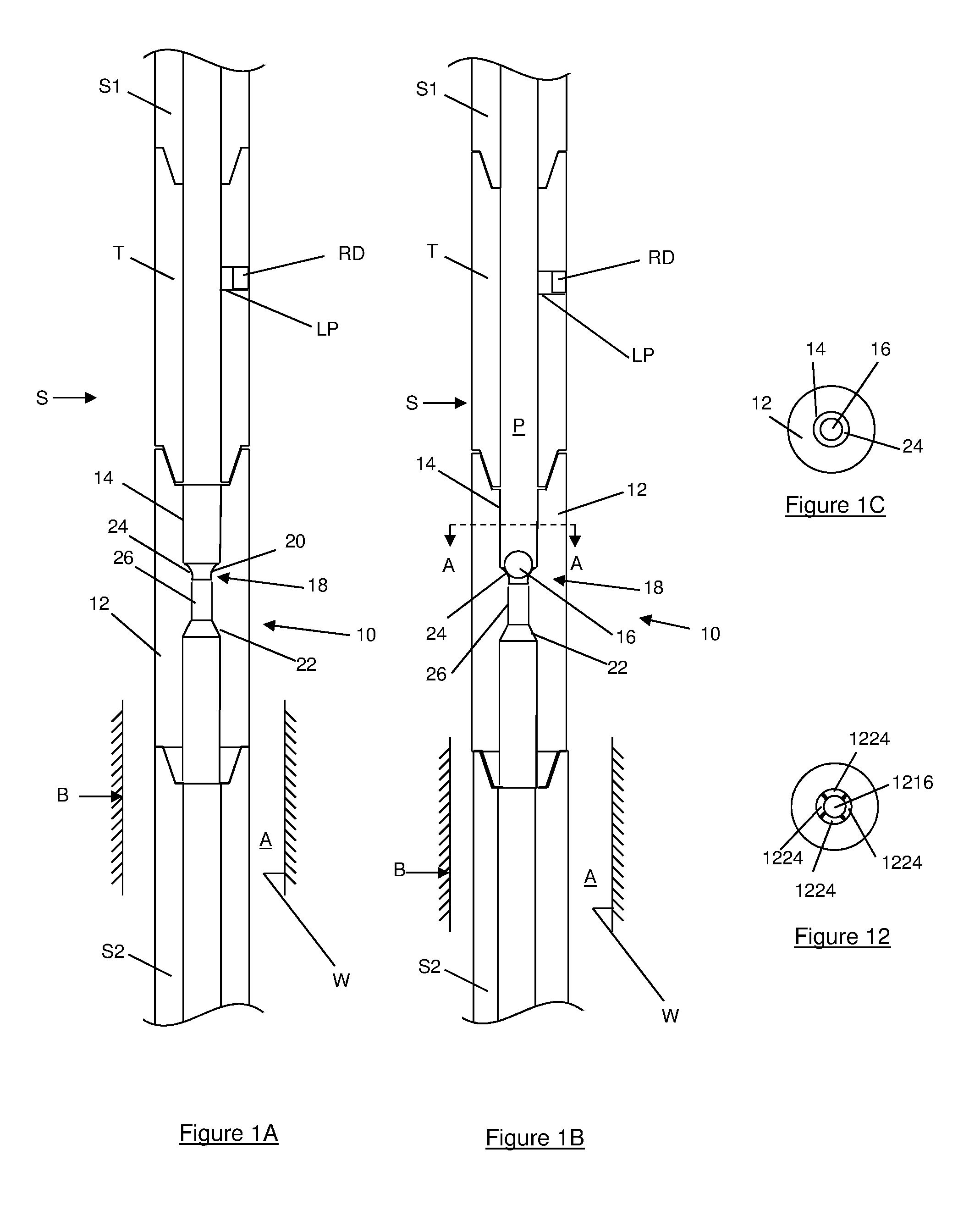

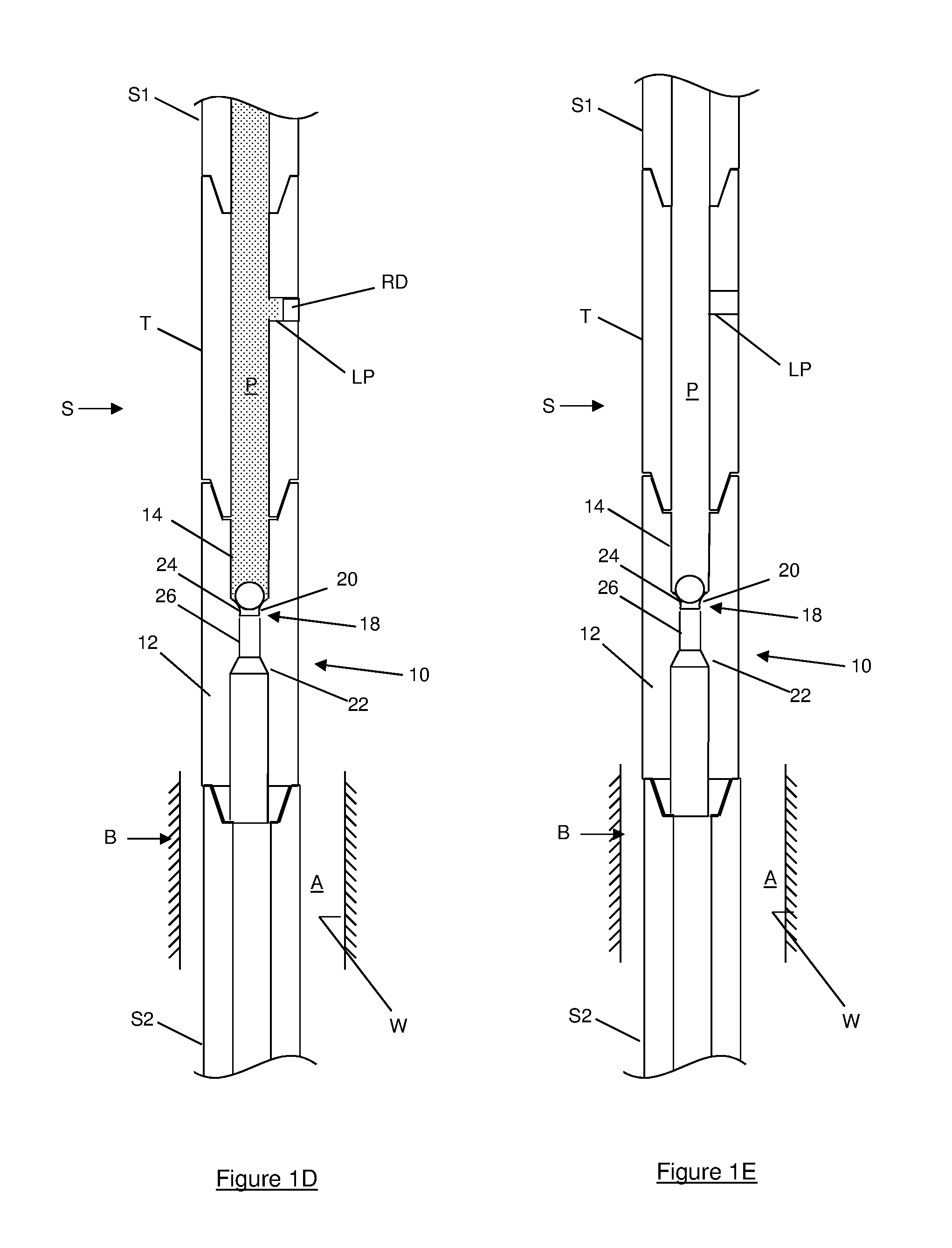

[0107]In this first embodiment, the apparatus 10 is configured so that the engagement between the ball 16 and the seat 18 seals or at least restricts fluid passage downstream of the seat 18 to increase upstream fluid pressure P, the increased upstream fluid pressure P being used to perform or permit a borehole operation to be carried out by activating the tool T. By way of example, the increased upstream pressure may exceed a threshold value required to burst the rupture disk(s) RD in the tool T to permit fluid communication between the throughbore 14 and annulus A disposed between the apparatus 10 and the wall W of the borehole B.

[0108]In use, the convex object engaging surface 24 provides an opposing, rather than complementary or matching, engaging surface for landing the ball 16 and provides a reduced or minimal contact surface, preferably a line or point contact, between the ball 16 and the seat 18, thereby preventing or at least mitigating the possibility of the ball 16 becomin...

Example

[0118]The apparatus 410 is similar to the second embodiment shown in FIGS. 2A to 2C, the difference being that apparatus sleeve 428 is coupled to a downhole tool T. In the illustrated embodiment, the downhole tool T comprises a sleeve 40. The downhole tool T is disposed downstream or downhole of the seat 418 and, in use, the ball 416 is dropped, pumped or otherwise motivated through the string S and into the bore 414 of the tubular body 412 until it lands on the seat 418, as shown in FIG. 4B. In this fourth embodiment, the apparatus 410 is configured so that engagement between the ball 416 and the seat 418 seals or at least restricts fluid passage through the tubular body 412 to provide a fluid pressure differential PD across the seat 418, the fluid pressure differential PD being utilised to perform or permit a borehole operation to be carried out, in this embodiment shear the shear pin 430 and move the sleeve 428 and sleeve 40 relative to the tubular body 412 from the position show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com