Off-road rolling film vision system

a vision system and film technology, applied in the field of protective hardware, can solve problems such as dirt and mud in the back of the vehicl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

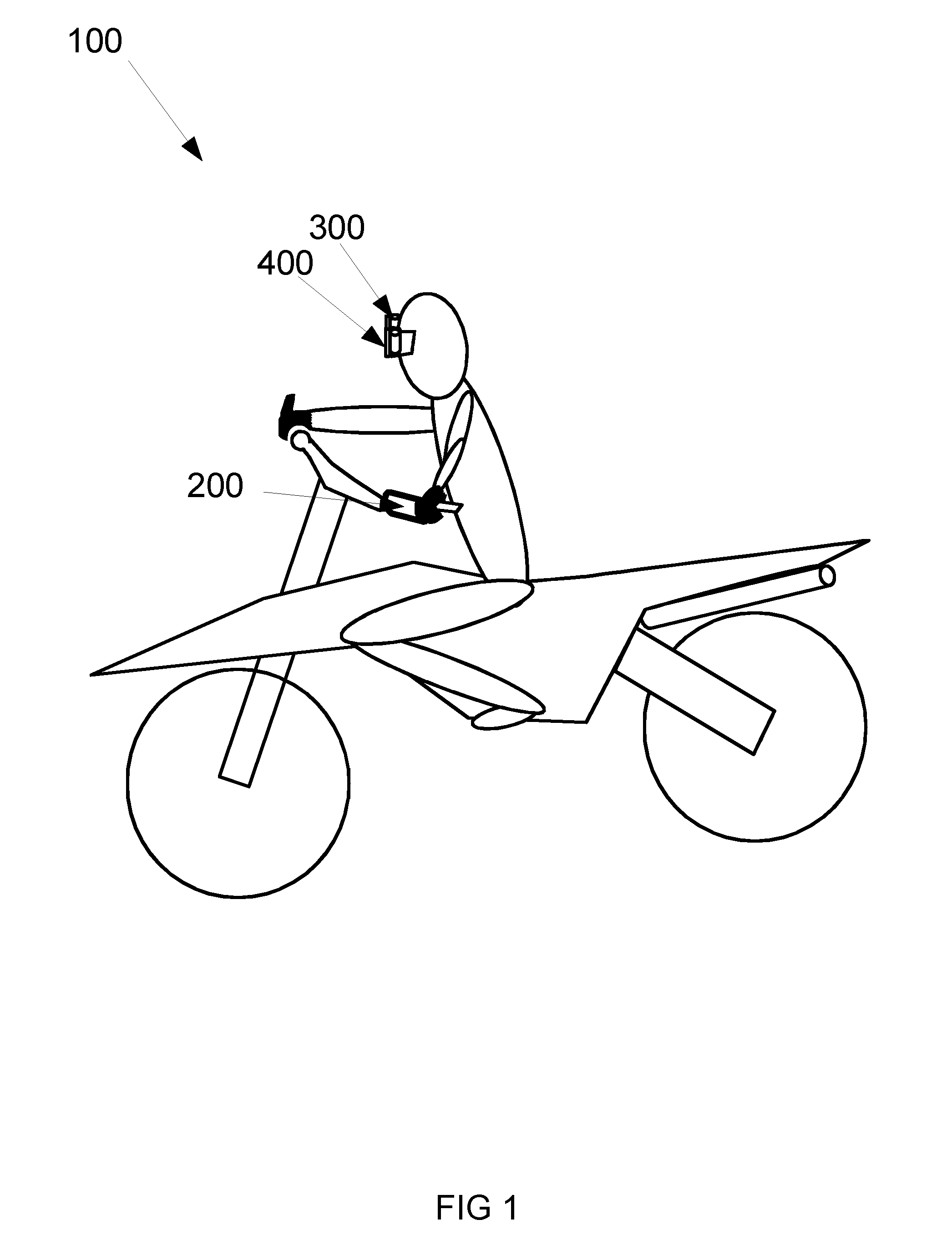

[0032]FIG. 1 shows an exemplary OFF-ROAD ROLLING FILM VISION SYSTEM (100) for giving off-road racers and other off-road fans a hands-free method of keeping their goggles or face shield clear of dust, mud and other debris by having a transparent film moving across the goggles or face shield to collect and remove the dust, mud and other debris. The exemplary OFF-ROAD ROLLING FILM VISION SYSTEM (100) comprises a Controller Module (200), a Takeup Module (300), and a Rollout Module (400). Details of the exemplary OFF-ROAD ROLLING FILM VISION SYSTEM (100) with a preferred and optional embodiments are subsequently described.

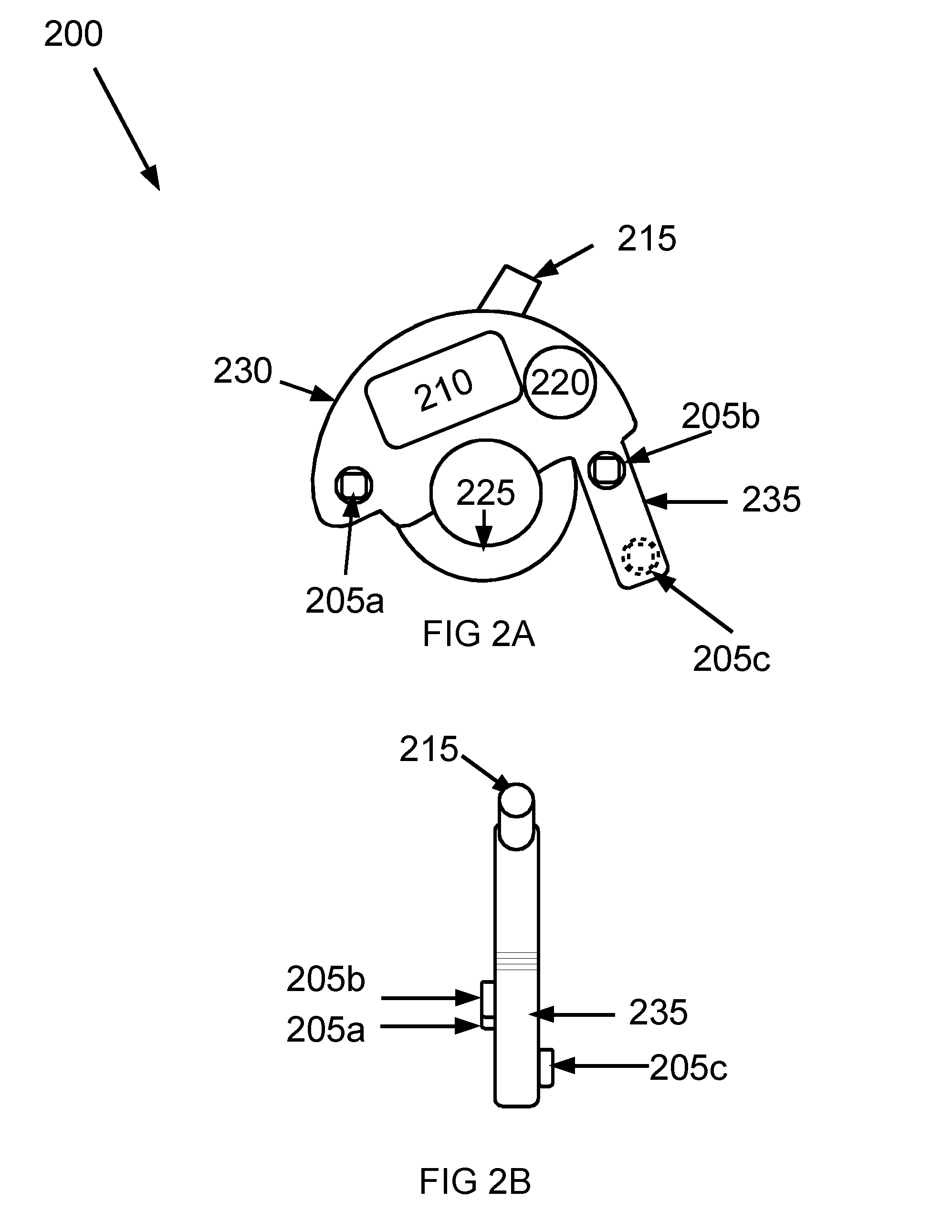

[0033]FIGS. 2A and 2B shows an embodiment of the Controller Module (200). The Controller Module (200) embodiment shown comprises a Command Input (205), a Controller Process Module (210), a Command Transmitter (215), a Power Supply (220), a Vehicle Attachment (225), a Housing (230) and a Controller Extension (235). Some embodiments comprise a Clothing Attachment (not sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| transparent | aaaaa | aaaaa |

| Transparent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com