Capsule and process for making the same

a technology of a plastic and a hole is applied in the field of plastic bags, which can solve the problems of difficult recycling, hardly implementable recycling operations of such products, and ineffective recovery operations of such materials, and achieve the effect of facilitating the opening of the hol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

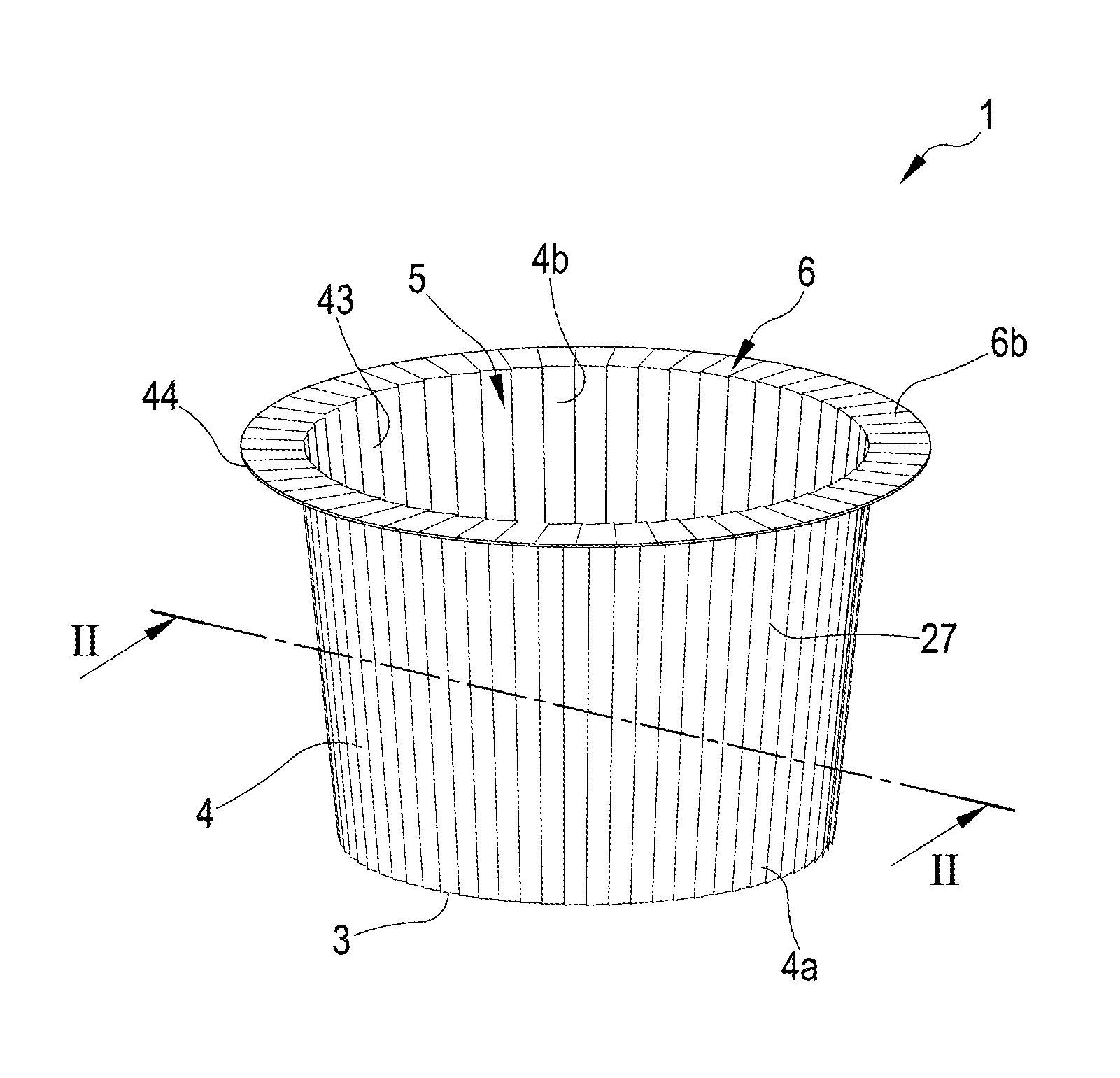

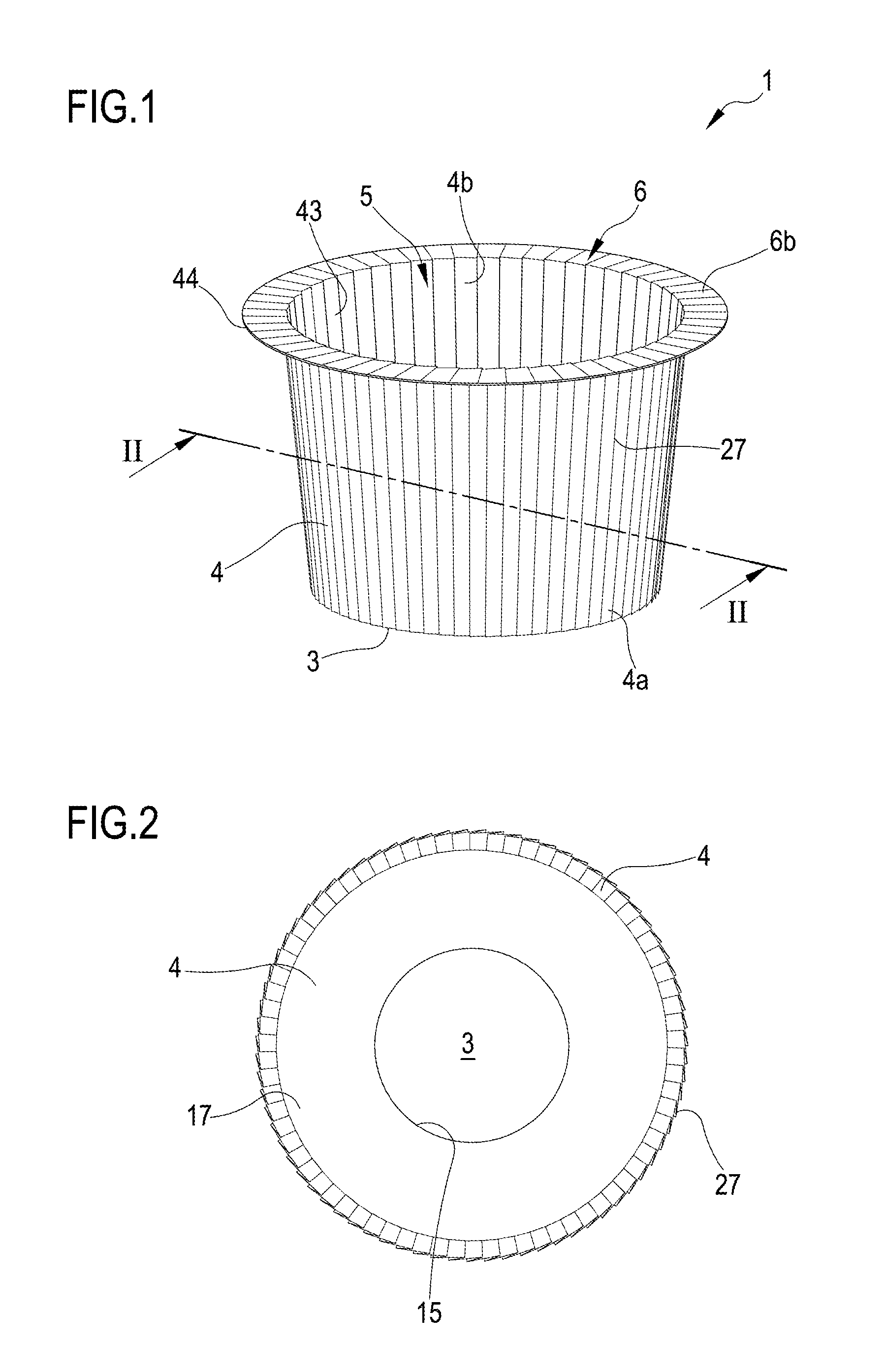

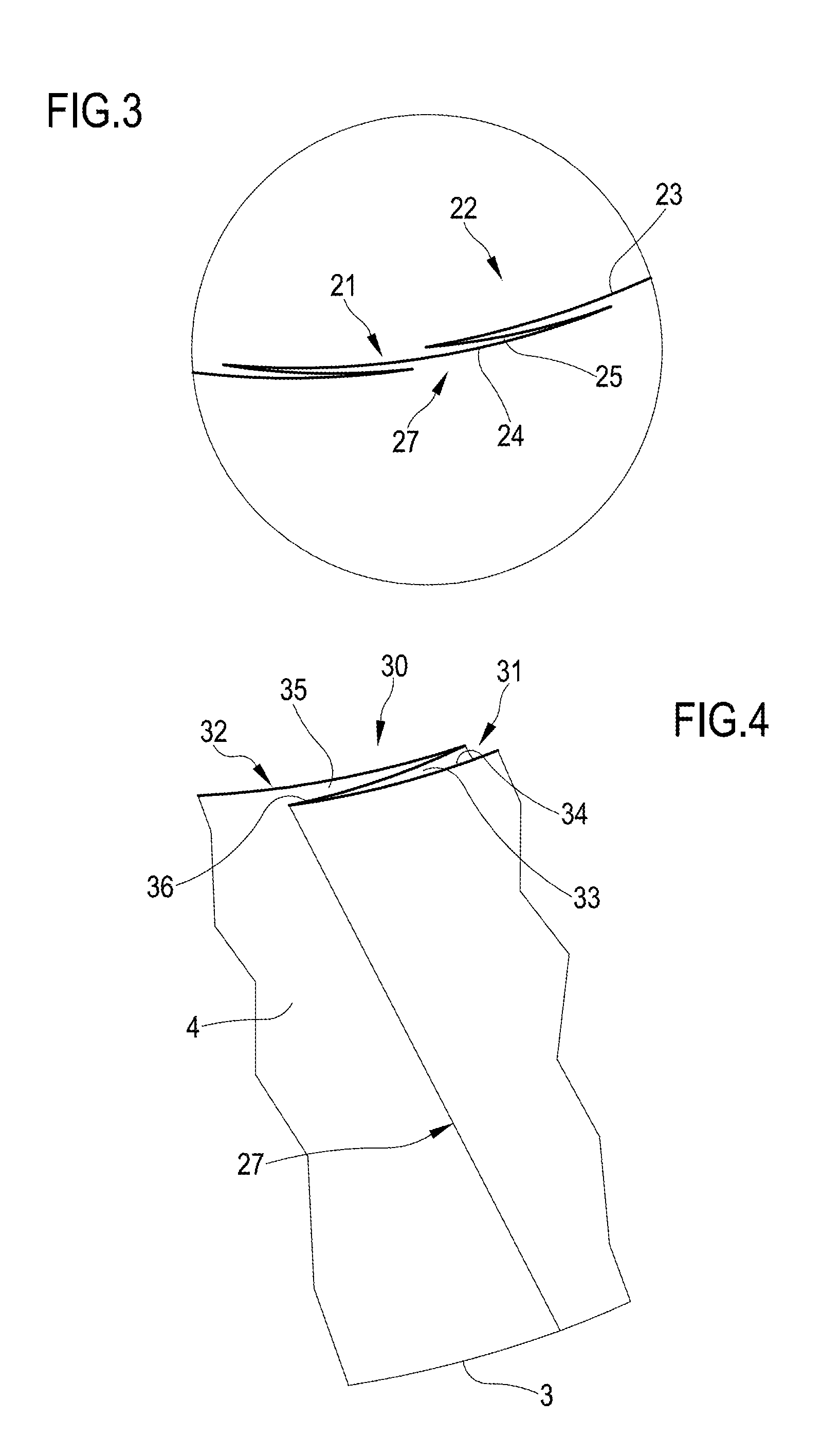

[0161]As shown in the Figures, 1 generally indicates a capsule for producing a beverage. The capsule 1, object of the present description, is particularly adapted to define a container for food products, as for example powdered coffee and / or tea and / or milk and / or fruit juices, and configured for enabling to dispense beverages.

[0162]The capsule 1 comprises a container 2, a reinforcing element 38 more possibly an inner stiffening body 14. The capsule 1, when is completed, will comprise also powdered coffee housed in the container 2 and a closure laminated element 13.

[0163]The capsule comprises a container made of paper sheet material exhibiting a first prevalent development surface 2a configured for at least partially defining the outer surface of the container and a second prevalent development surface 2a, opposite to the first surface 2a, and adapted to define at least partially the container 2 inner surface.

[0164]The sheet material forming the container 2 is made of paper o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com