Methods for joining cutting elements or other components to earth-boring tools and related methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

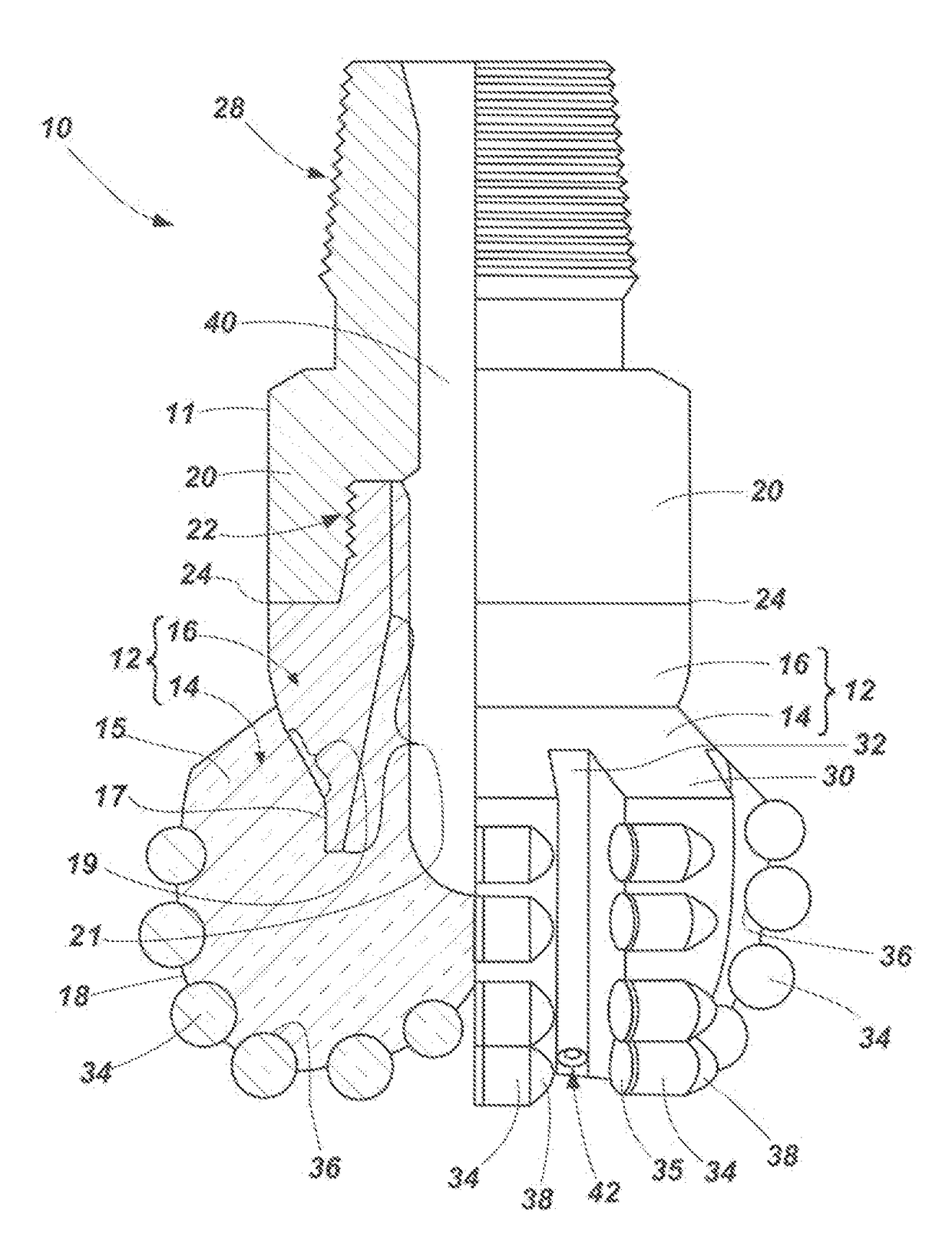

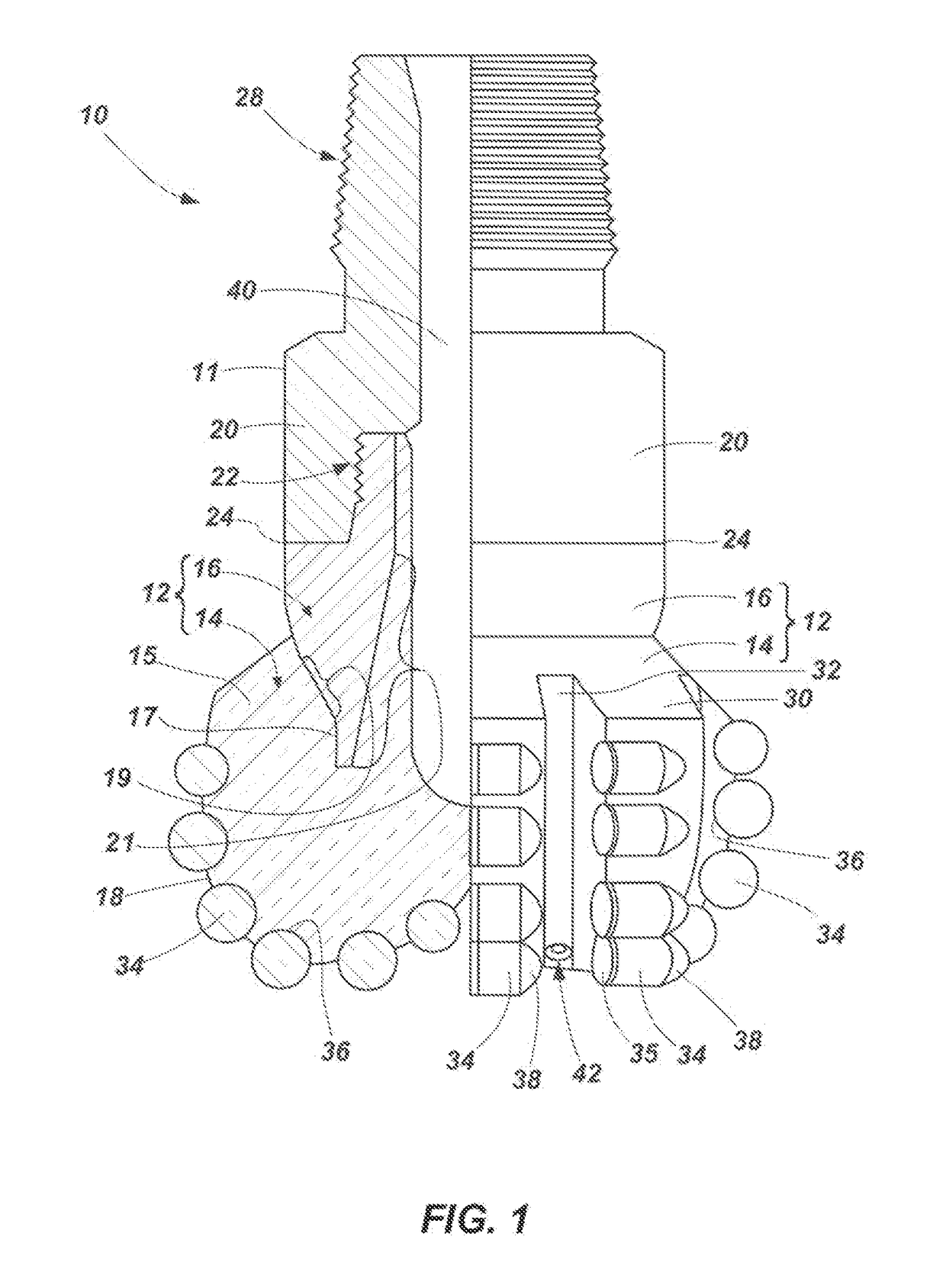

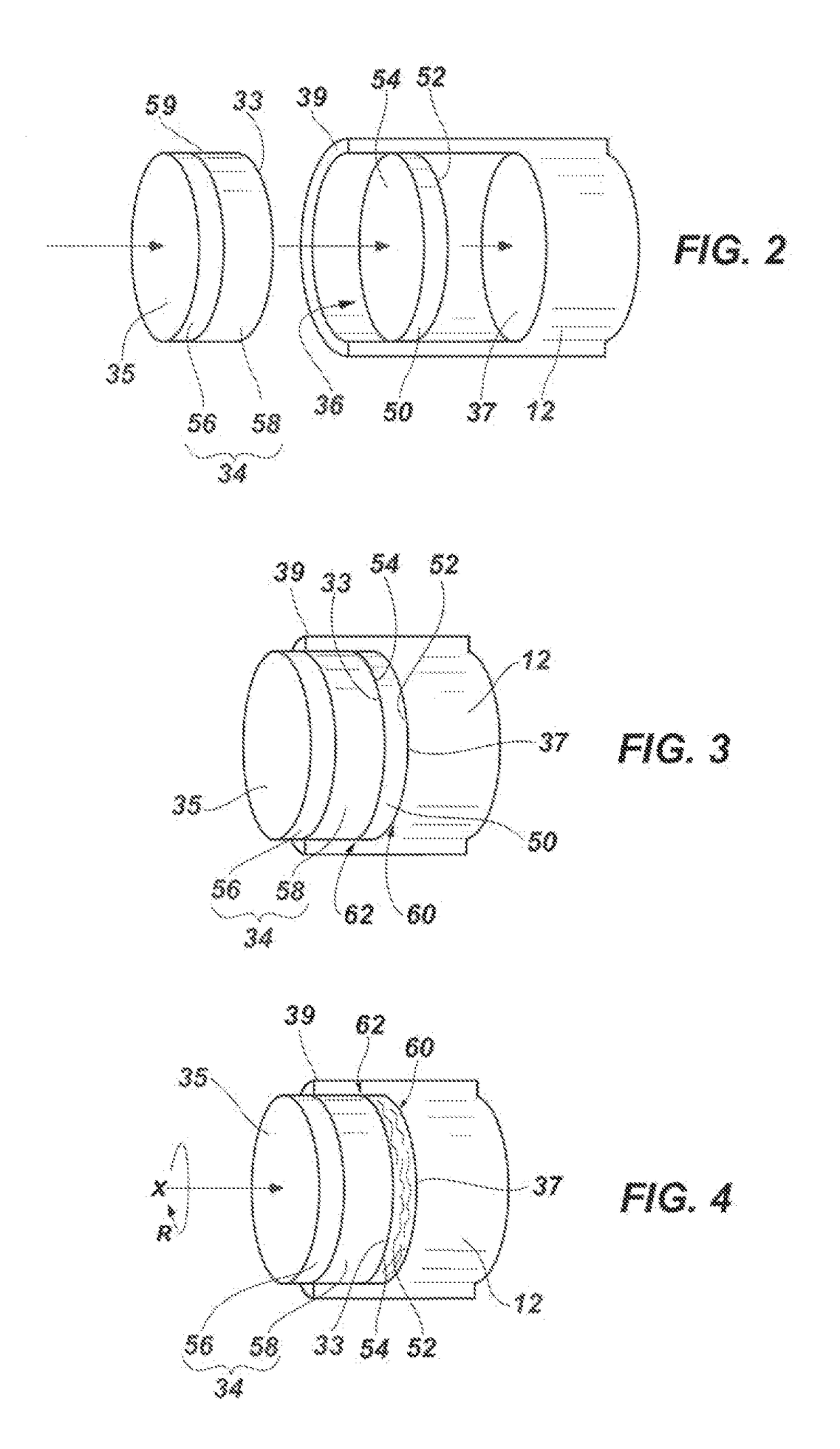

[0073]A method of joining a cutting element to an earth-boring tool, the method comprising: disposing a cutting element in a pocket defined in a body of the earth-boring tool with a third-body structure between a surface of the cutting element and a surface of the body within the pocket; providing relative movement between the third-body structure and at least one of the surface of the cutting element and the surface of the body within the pocket to generate frictional heat within and at least plasticize material of the third-body structure; and after providing the relative movement, compressing and at least plastically deforming at least a portion of the material of the third-body structure between the surface of the cutting element and the surface of the body within the pocket.

embodiment 2

[0074]The method of Embodiment 1, wherein the surface of the body within the pocket comprises a floor of the pocket.

embodiment 3

[0075]The method of any one of Embodiments 1 and 2, wherein the material of the third-body structure comprises a braze material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap