Ferritic stainless steel having excellent ductility and method for manufacturing same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062]Molten steels having the compositions shown in Table 1 were prepared and were cast at a constant speed under the conditions shown in Table 2 in order to produce slabs. The slabs were subjected to a hot rolling process and a hot band annealing process to obtain hot-rolled sheets. In Table 1, the contents of elements are given in wt %, and in Table 2, the slab cooling rate is an average cooling rate measured based on the surface temperature of a slab within the temperature range of 1100° C. to 1200° C.

TABLE 1SteelCSiMnPSCrTiAlNA0.0120.250.160.0310.00311.00.150.0400.012B0.0150.350.80.0250.00212.00.210.0320.015

TABLE 2Slab Cooling RateHot BandHot Band(° C. / sec) within theAnnealingAnnealingTemperature Range ofTemperatureTimeSteel1100° C. to 1200° C.(° C.)(min)NotesA260030InventiveExample 1A280015InventiveExample 2A680015ComparativeExample 1B190015InventiveExample 3B690015ComparativeExample 2

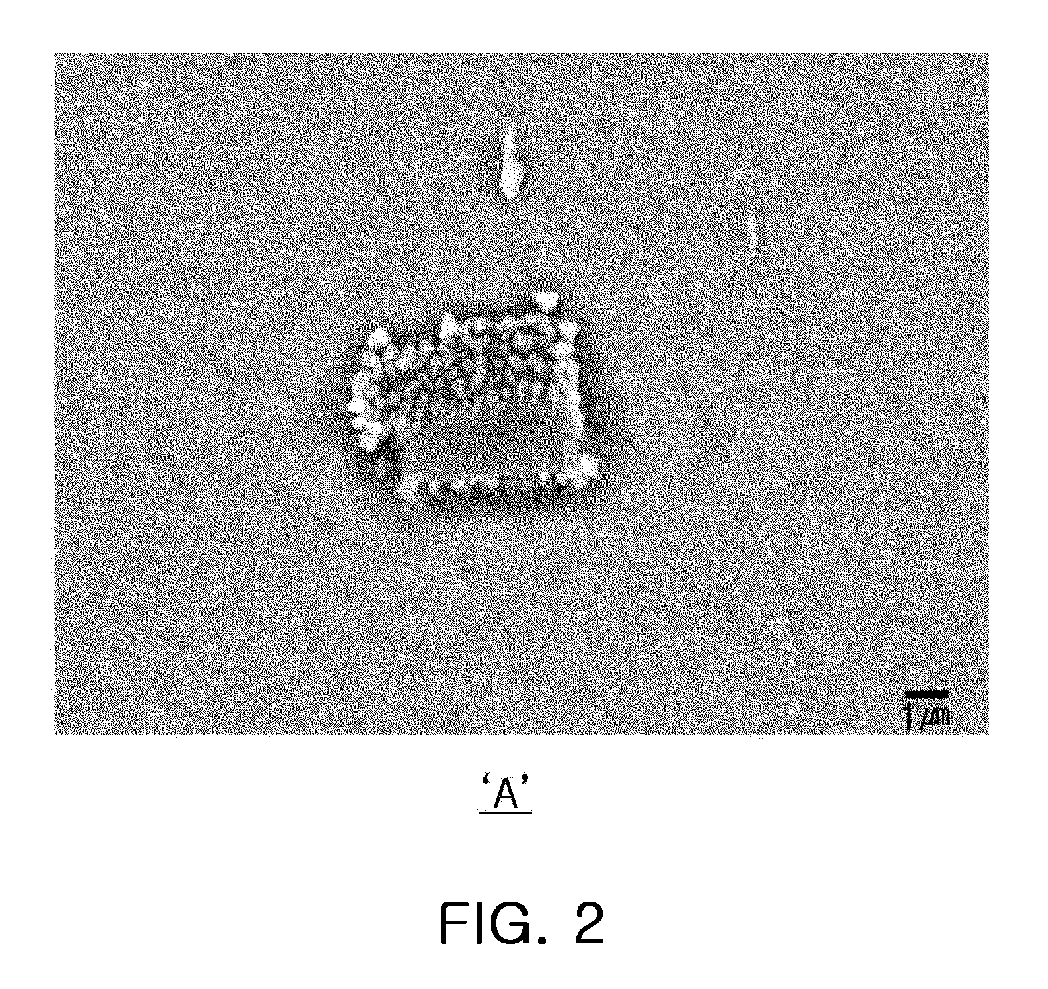

[0063]Thereafter, the hot-rolled sheets were photographed using a transmission electron micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com