Substrate and manufacturing method of substrate

A manufacturing method and substrate technology, which are applied in the direction of multi-layer circuit manufacturing, electrical connection of printed components, printed circuit components, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

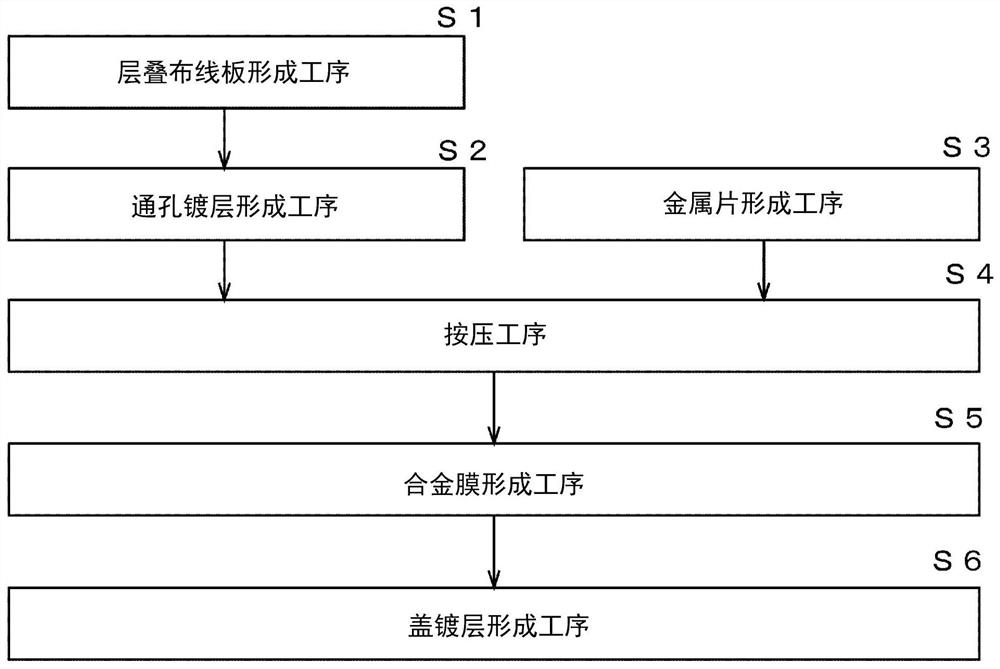

Method used

Image

Examples

Embodiment Construction

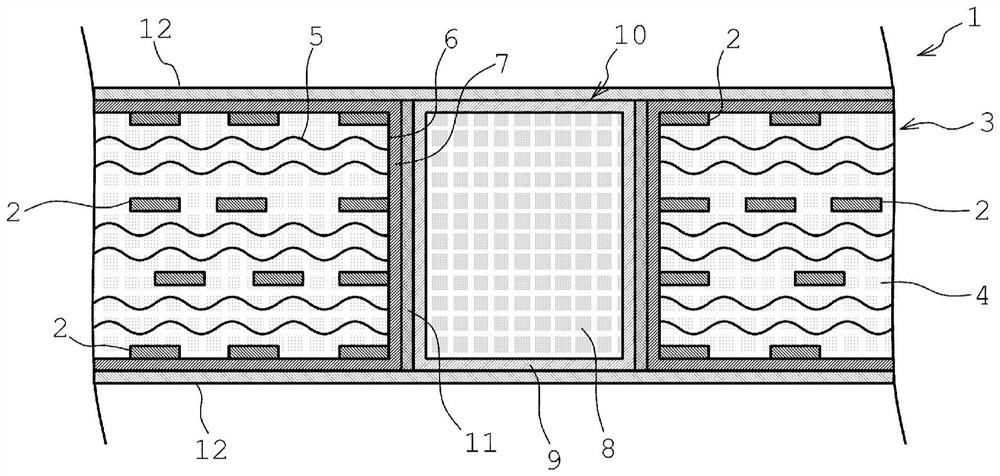

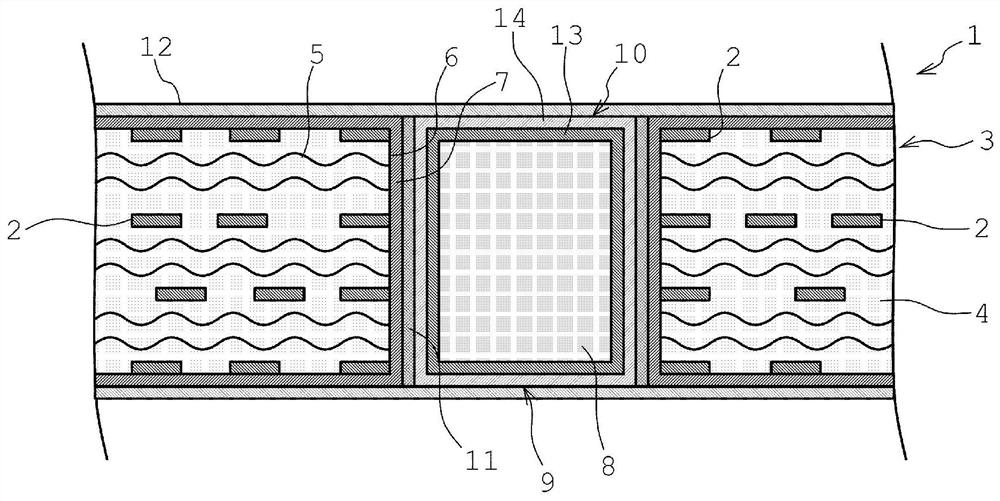

[0034] Such as figure 1 As shown, the substrate 1 of the present invention is mainly constituted by a laminated wiring board 3 called a multilayer board (including double-sided boards) on which a plurality of conductive layers 2 are formed. exist figure 1 In the example of , a so-called four-layer board formed with four conductive layers 2 is shown. The conductive layer 2 is formed on each layer as a conductive pattern. An insulating layer 4 is disposed between the conductive layers 2 . The insulating layer 4 is formed of insulating materials such as prepreg, for example.

[0035] Through holes 6 are formed in the laminated wiring board 3 . The through hole 6 penetrates the laminated wiring board 3 . The hole shape of the through hole 6 is substantially cylindrical. In plan view of laminated wiring board 3 viewed from above, through hole 6 draws a circular shape. A through hole plating layer 7 is formed on the inner wall of the through hole 6 . This through-hole platin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com