Profiled rail system for covering the end of a flooring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

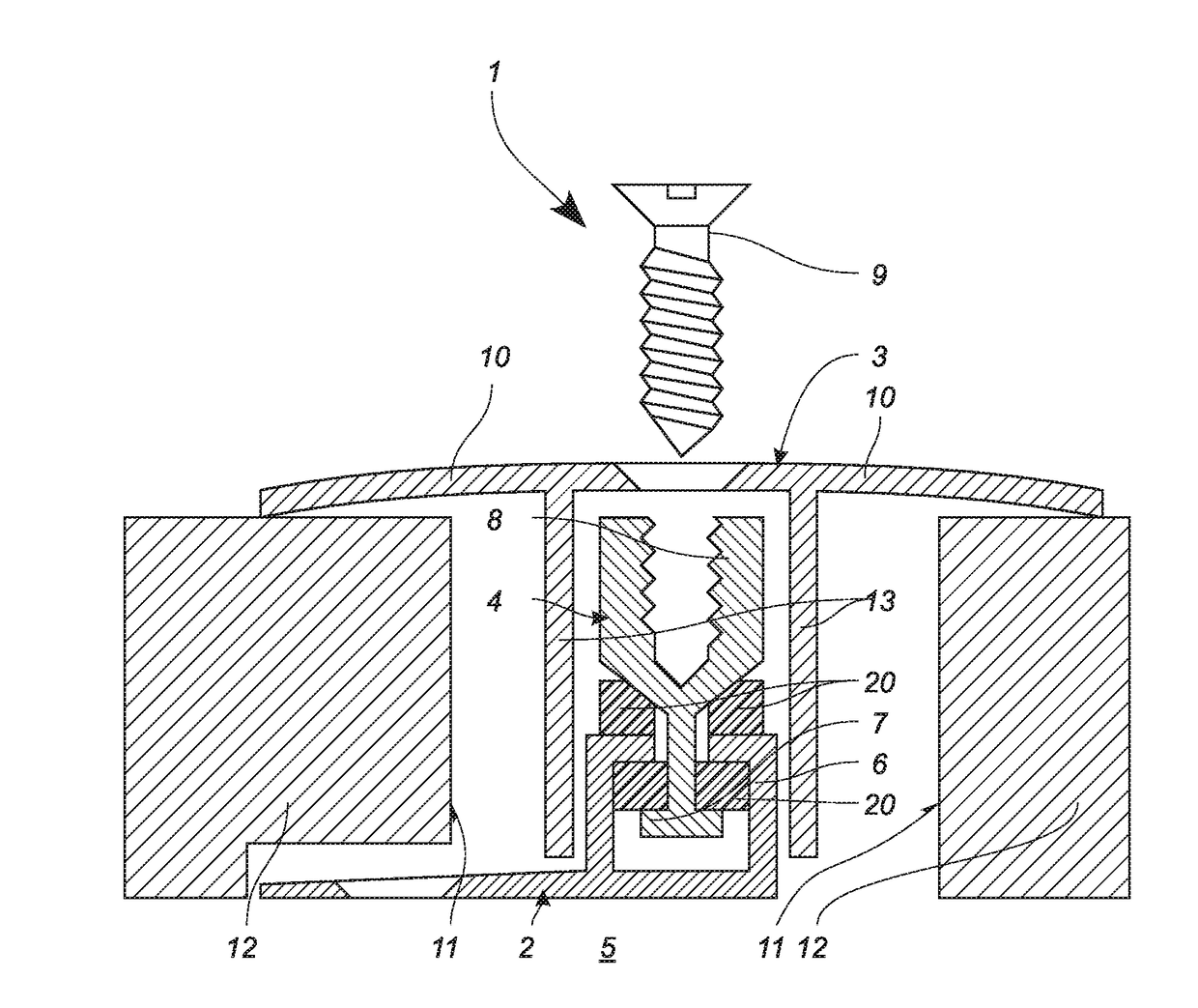

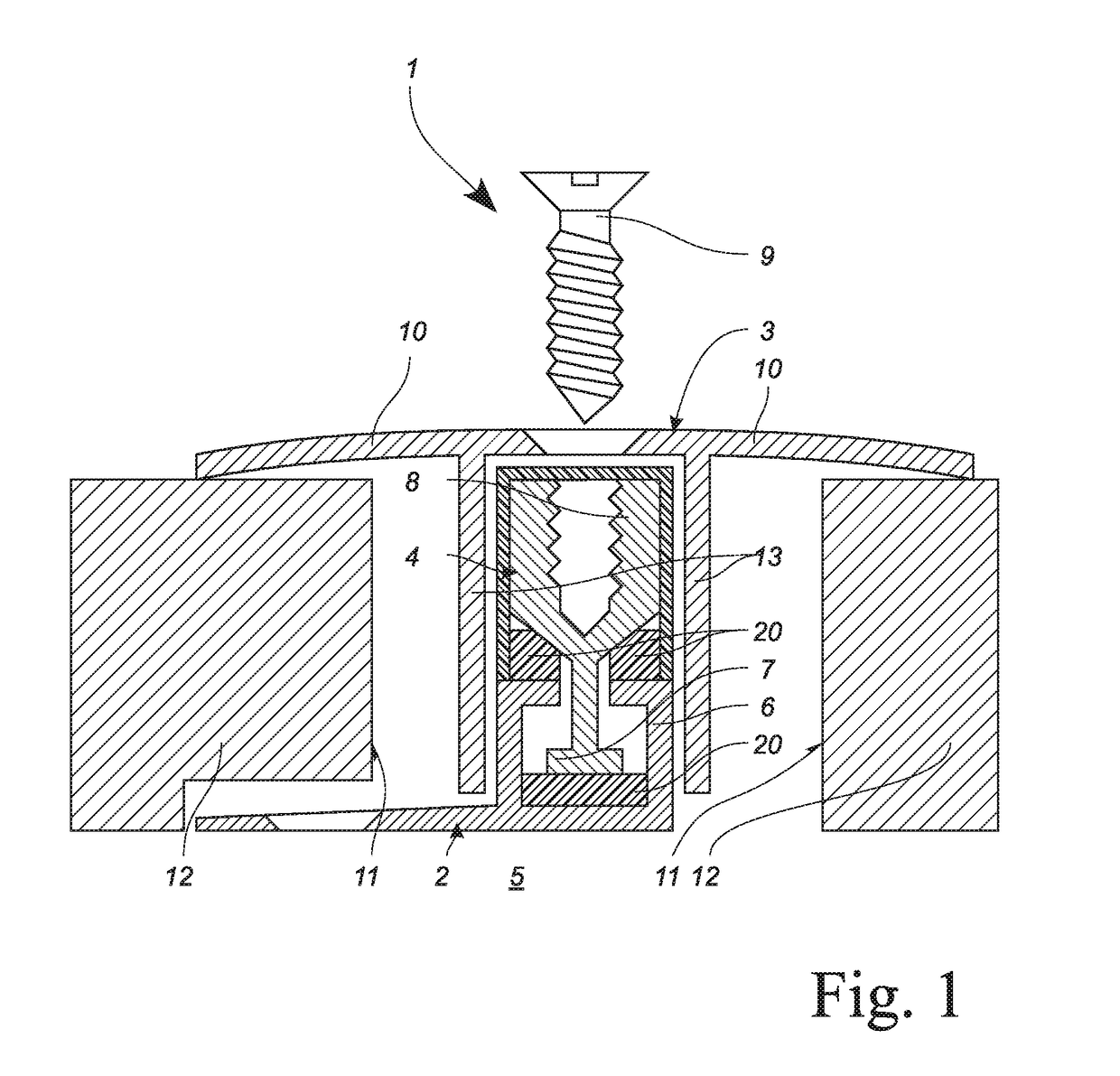

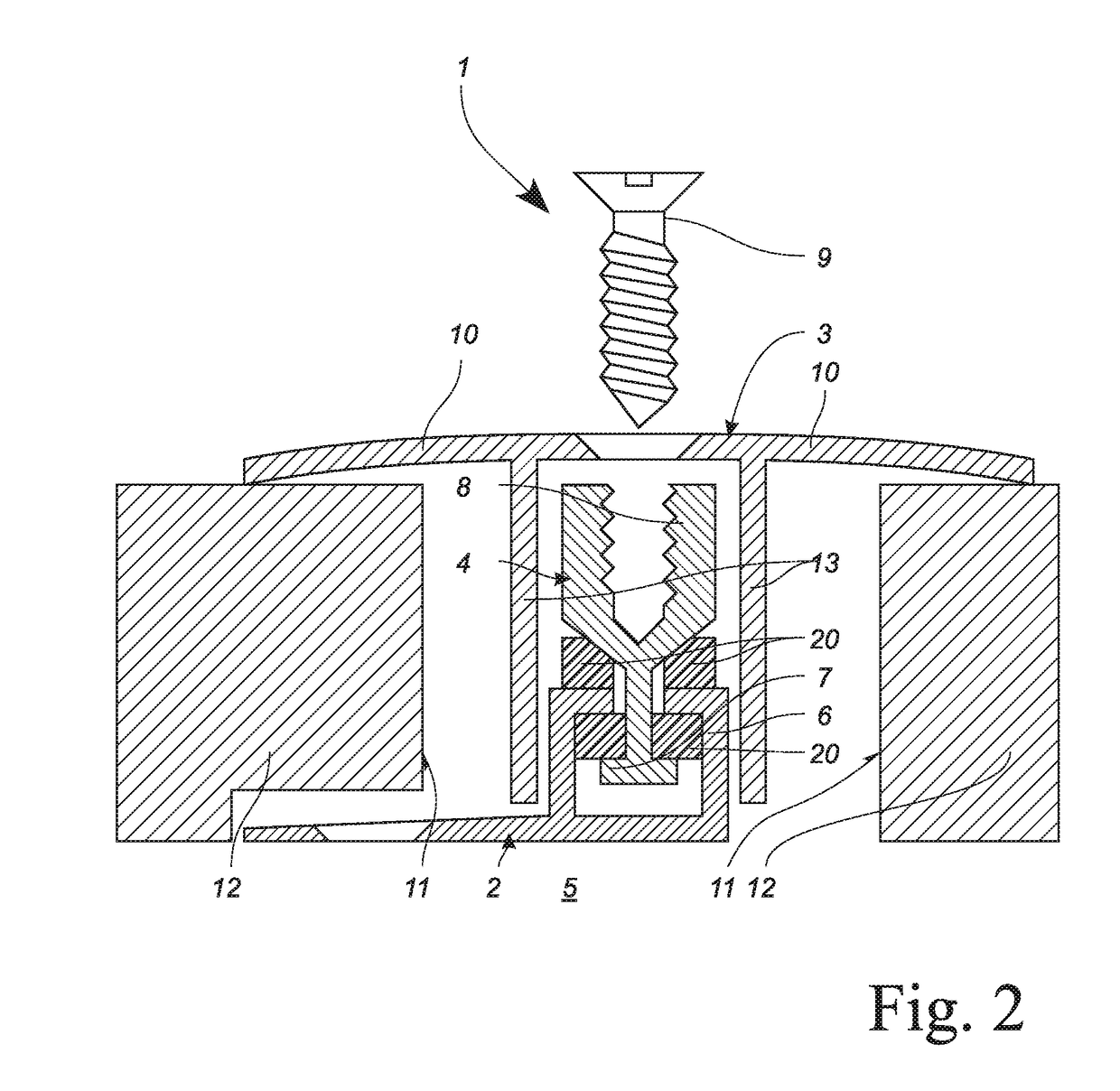

[0020]FIG. 1 shows a cross section of a profiled rail system 1, comprising a base profiled rail 2, a covering profiled rail 3 and a mounting profiled rail 4. The base profiled rail 2 is mounted by means of non shown mounting means, in particular screws with an underground 5. The base profiled rail 2 comprises mounting means 6, being realised by means of vertically extending webs, being deviated to the interior at the top end. Between holding means 6 a foot 7 of the mounting profiled rail 4 is provided. This foot 7 is made sufficiently broad, to realise a top abutment for the holding means 6 of the mounting profiled rail 4, in order to safely hold the mounting profiled rail 4 on the base profiled rail 2.

[0021]The mounting profiled rail 4 provides a mounting channel 8 for receiving further holding means 9 in form of a screw. These holding means 9 connect the covering profiled rail 3 with the mounting profiled rail 4. By means of more or less deep turning of the holding means 9 a certa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com