Articulated dismountable modular scaffolding

a technology of modular scaffolding and articulating parts, which is applied in the direction of scaffold connections, building scaffolds, building aids, etc., can solve the problems of safety, ease and speed of assembly of none of these devices, and versatility of us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

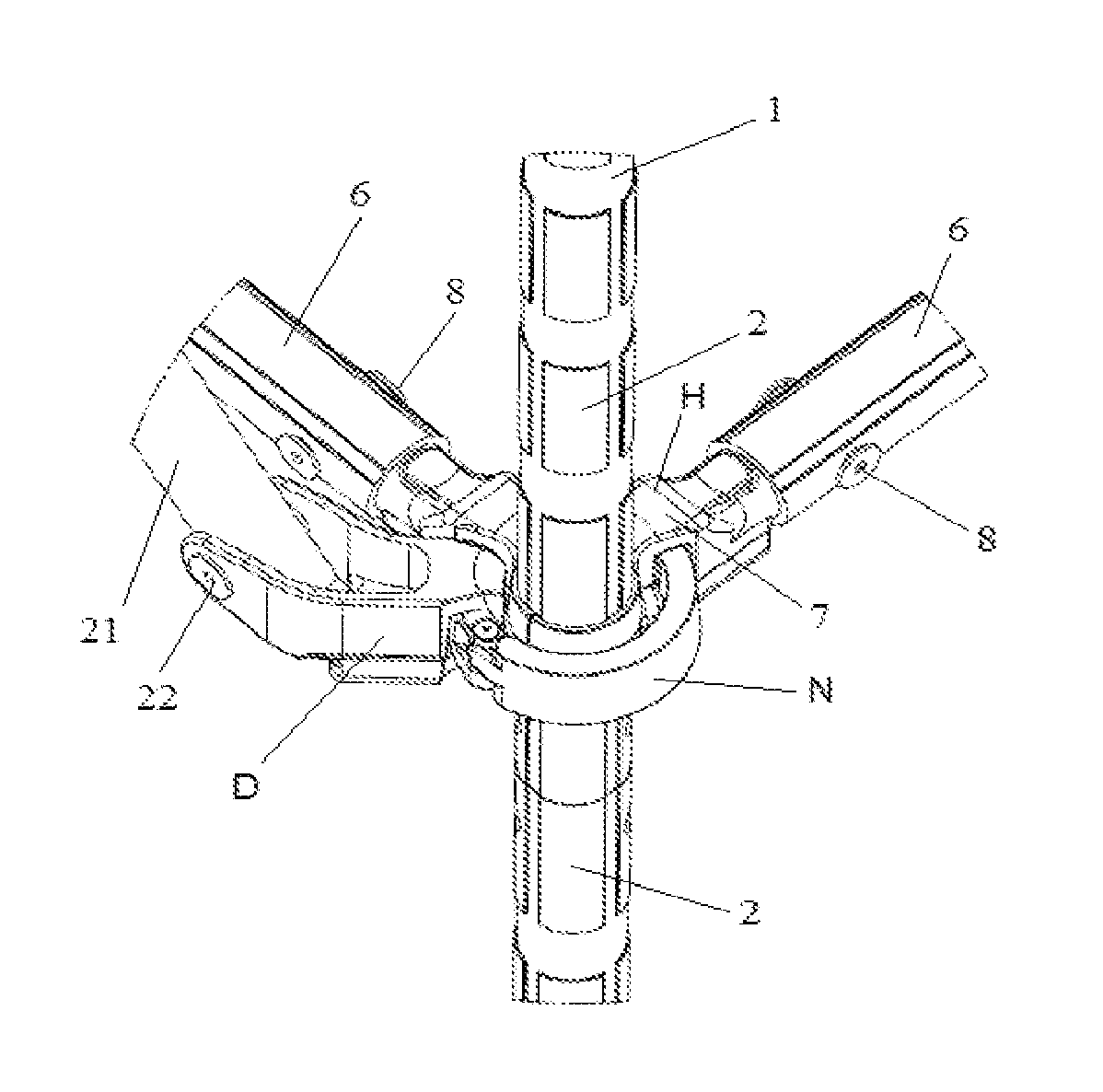

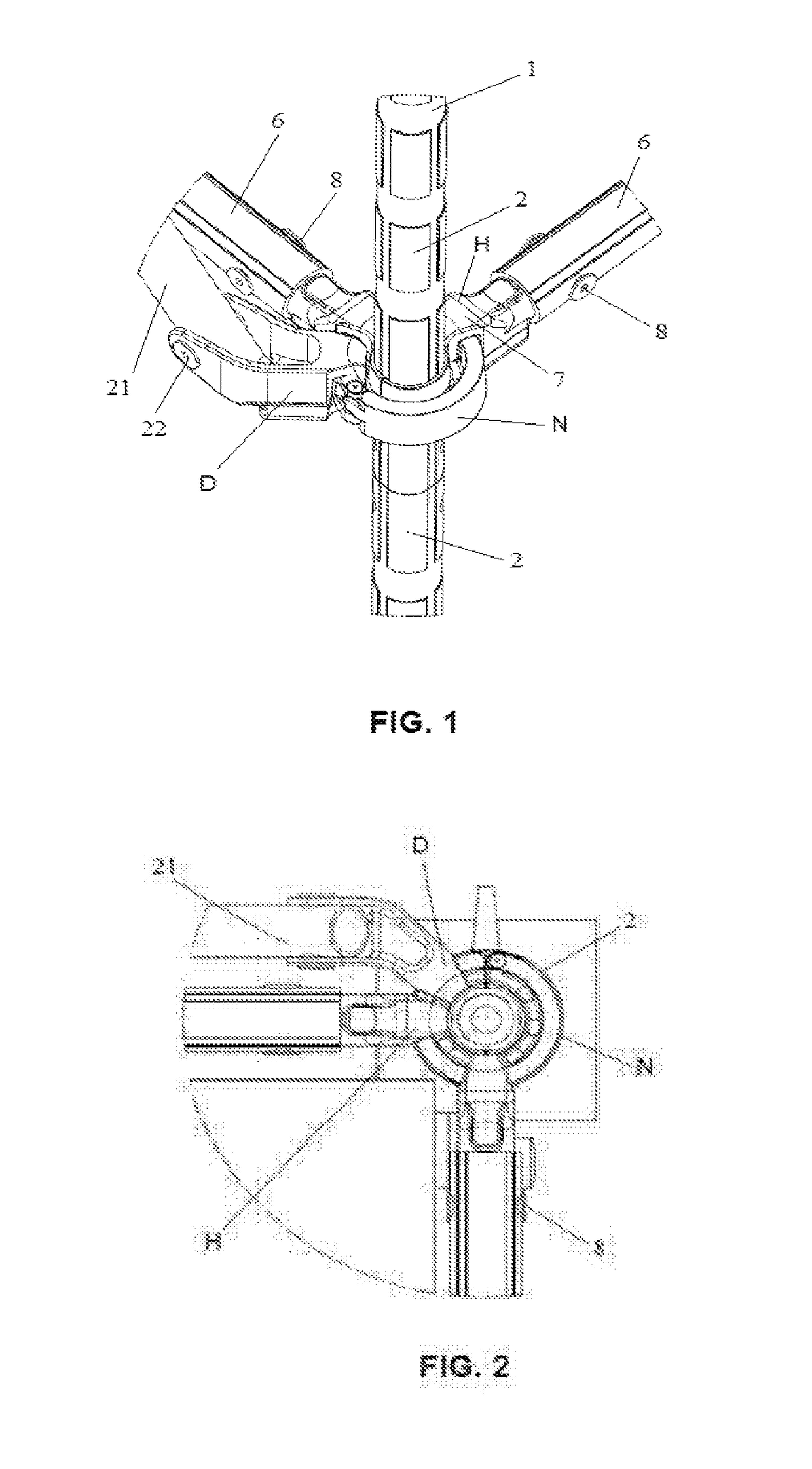

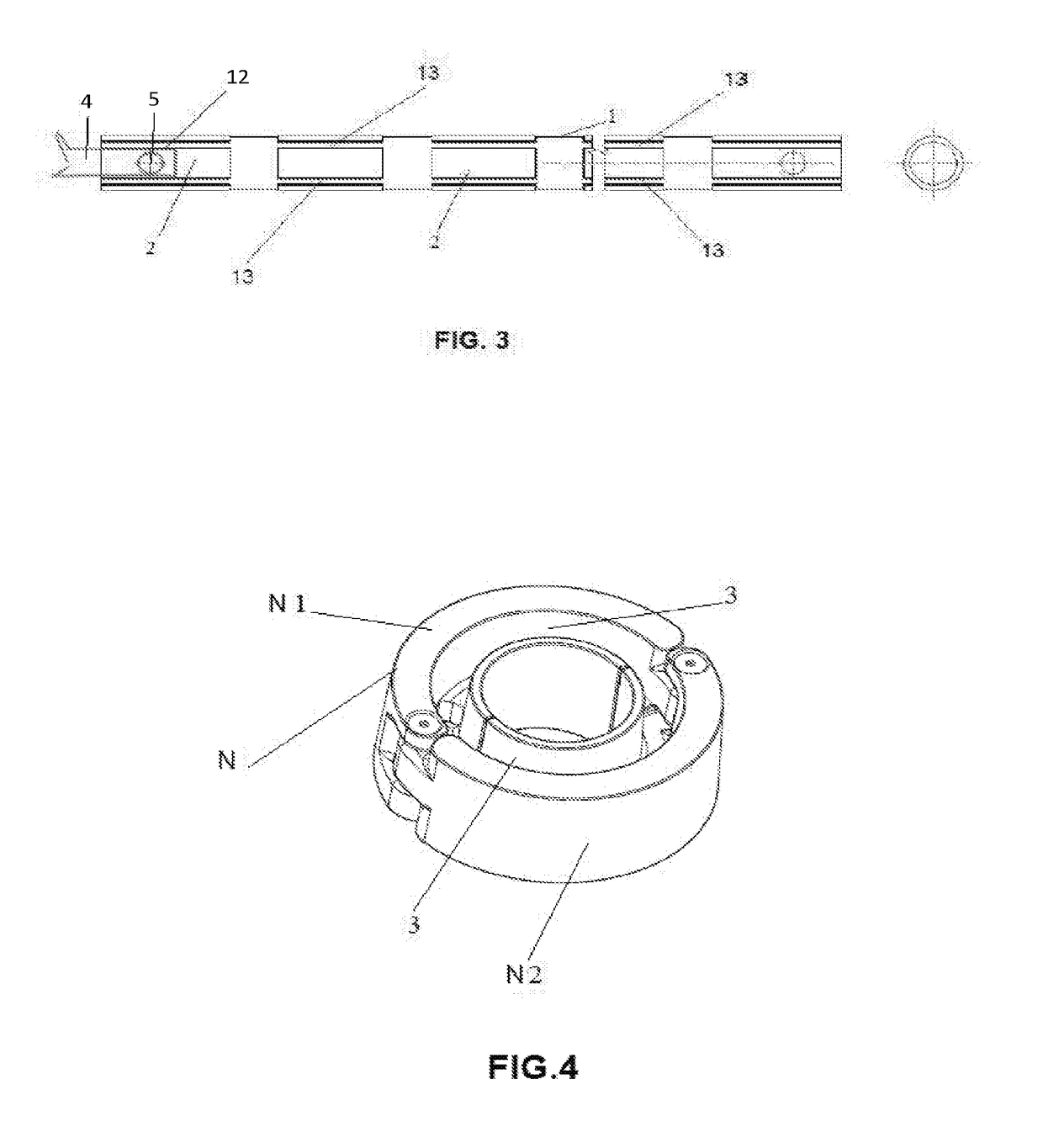

[0016]The invention put forward refers to an articulated dismountable modular scaffolding of the type assembled at the workplace by means of parts comprising a structure that can be assembled and disassembled, perfectly adaptable to each type of work.

[0017]The system presented intends to provide flexibility regarding the position of the joints, improving the rigidity of traditional scaffolding while also achieving greater ease when fixing and releasing the parts at the joint, avoiding wedge and hammer systems.

[0018]Similarly, it intends to provide greater safety to the assembly personnel by means of easier fixing and releasing movements.

[0019]The articulated dismountable modular scaffolding is a structure that can be assembled and disassembled made up by:

[0020]—vertical tubes,

[0021]—joints,

[0022]—horizontal and diagonal bars,

[0023]—horizontal and diagonal fastenings,

[0024]—diverse adjustment material such as spigots, pins and sleeves, and pull handles.

The joints are the points where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com