Convertible garment

a convertible garment technology, applied in garments, apparel, applications, etc., can solve problems such as broken tubular base integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

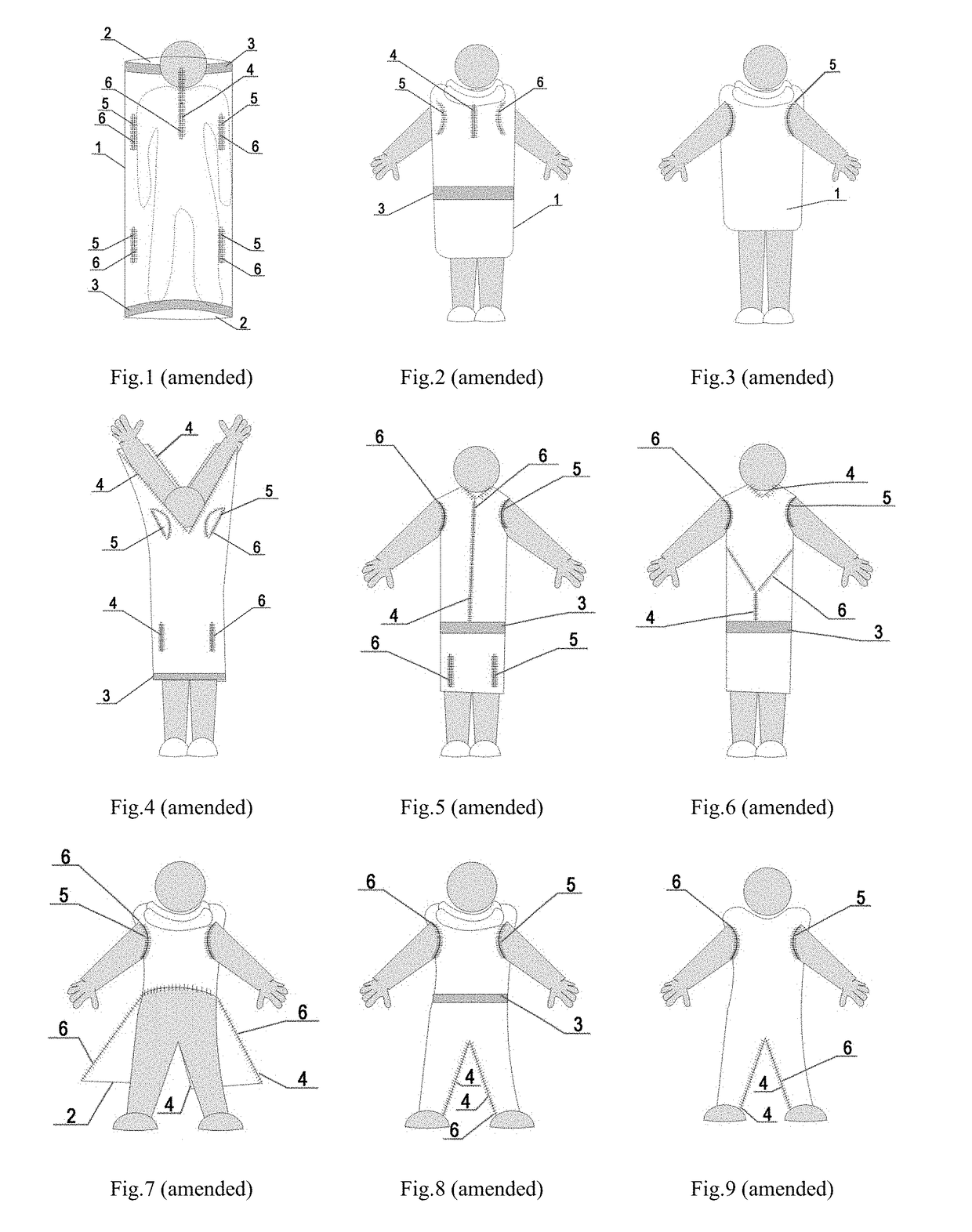

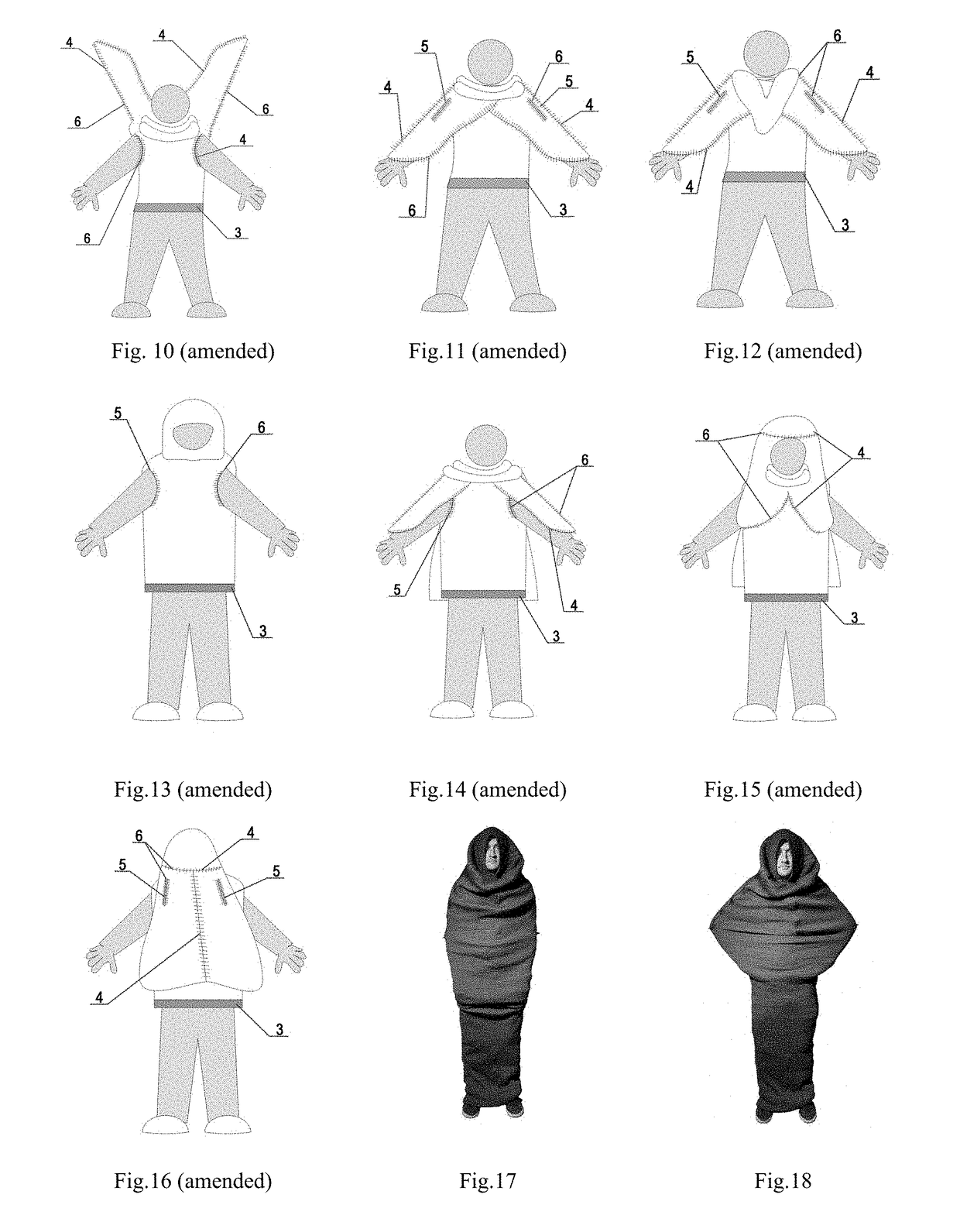

[0048]The initial convertible garment is a Rain Poncho, when it is used in vertical position, or sleeping bag, when it is used in horizontal position. It can be used independently or in combination with another sleeping bag, which is outside, or with blanket.

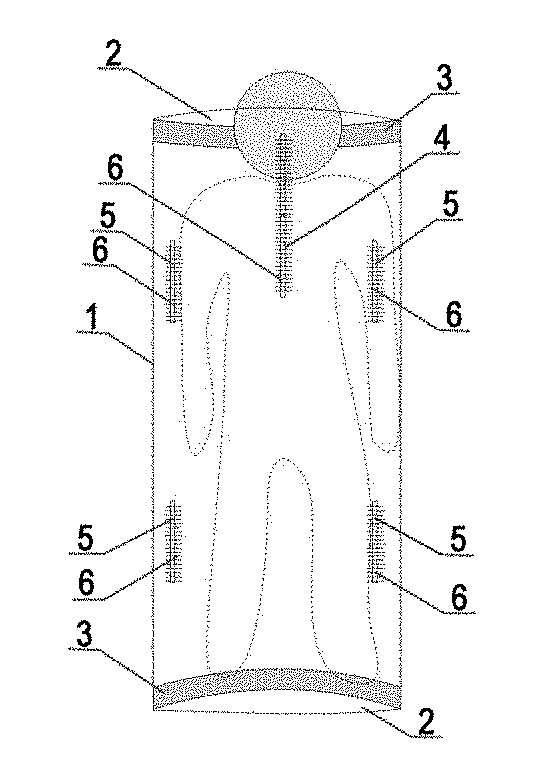

[0049]The tubular base 1 is made of sleeve fabric, made of woolen and synthetic yarn. The initial garment is easily converted into a sleeping bag. In such a case, the conversion lines 4 are on the side of the user's head, and the lower neck hole 2, created by the sealing device 3, represented by the rubber tape, which goes along the perimeter of the neck hole 2. At the discretion of user, the neck hole 2 on the side of his head can be also created by means of the sealing device 2, which is made of the rubber tape, which goes along the perimeter of the neck hole 2, and his facepiece comes in contact with the ambient environment by means of partial opening the conversion line 4, which is on the side of the face, that is provided b...

example 2

[0050]The material of the tubular base 1, sealing device 3 and fixing elements are the same as in the example 1.

[0051]Conversion of “Rain Poncho” into “Skiff” jacket.

[0052]User opens the conversion areas 5, located on the side of the head, wherefore he unfastens the fixing elements 6, designed as zip-fasteners, pulls hands out of them, whereafter lifts the lower neck hole 2 to the level of his waist, that is fixed thereon due to the sealing device 3, made of the rubber tape. On the side of the upper neck hole 2 user partially opens conversion areas 4, and on the basis of the panels, being formed by the upper part of the tubular base 1, he creates a collar around his neck, wherefore he partially fastens the conversion lines 4 by means of the fixing elements 6.

example 3

[0053]Conversion of a “Skiff” into “Waistcoat”.

[0054]The material of the tubular base 1, sealing device 3 and fixing elements are the same as in the example 1.

[0055]User, previously unfastens fixing elements 6 on the conversion lines 5, which are on the side of the lower neck hole 2 of the tubular base 1, then lifts the lower part of the tubular base 1, pushes his hands through the conversion lines 5, located in the lower part, whereafter he pulls the lower neck hole 2 to the level of his neck and fixes around it by means of the sealing device 3, and on the basis of the upper part of the tubular base 1 he forms a collar, or a hood, wherefore he uses the upper neck hole 2, which goes along the perimeter of the face and due to the sealing device 3, fits close the contact line. At this time the conversion lines 4 are not used and fixing elements 6 thereon are fastened.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com