Rigid connection structure between upper precast concrete column and lower precast concrete column and rigid connection structure of precast concrete beam using the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

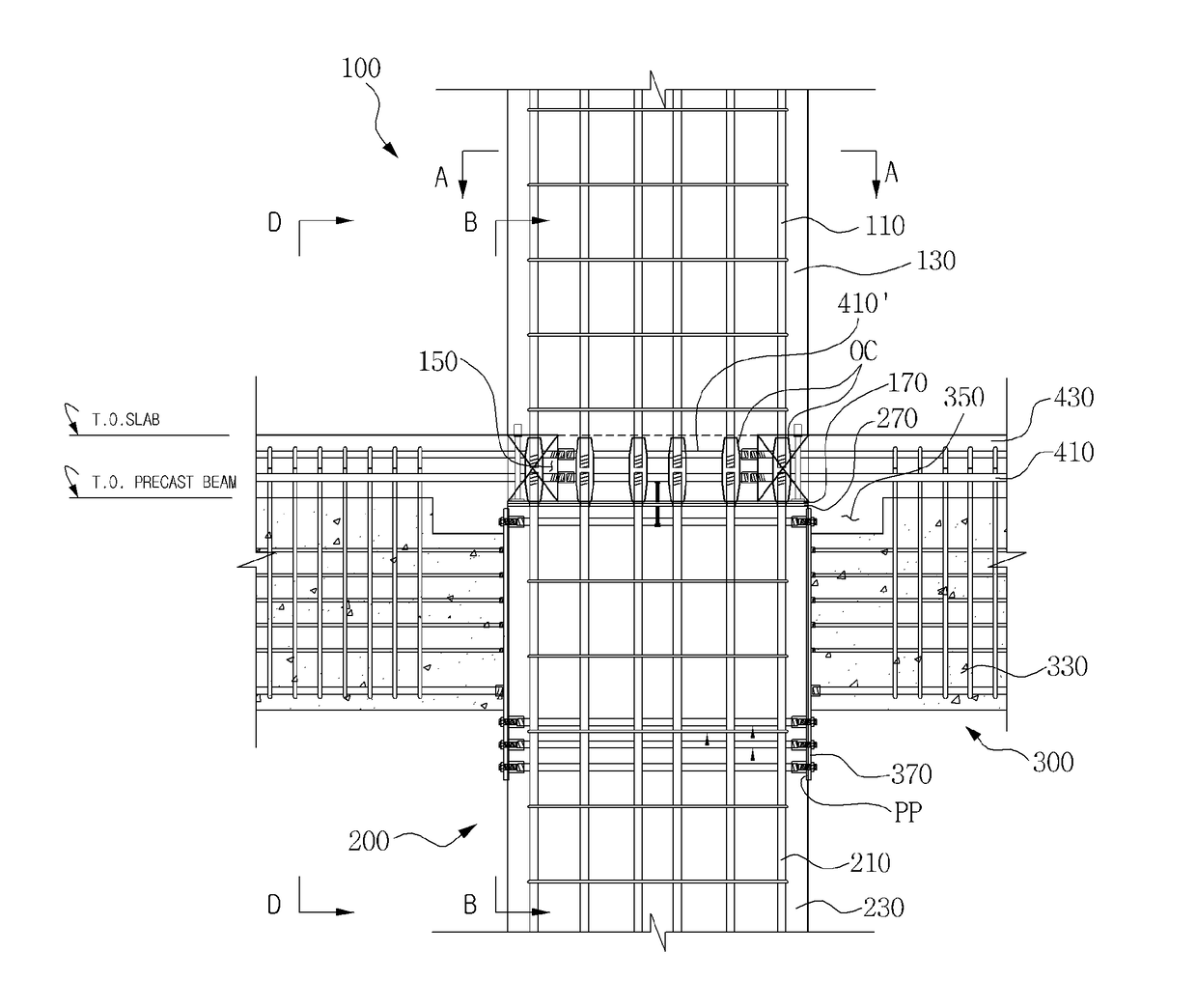

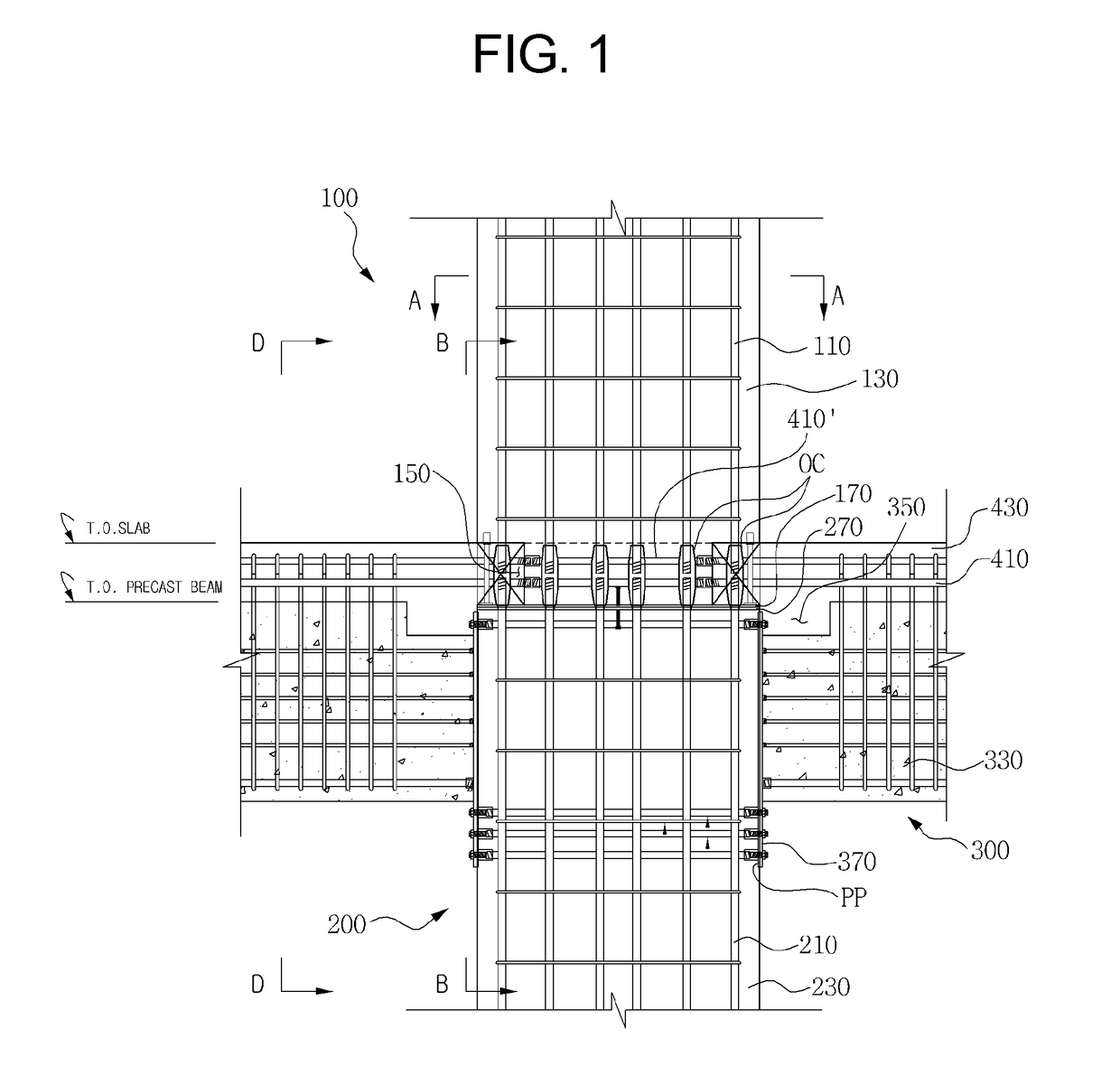

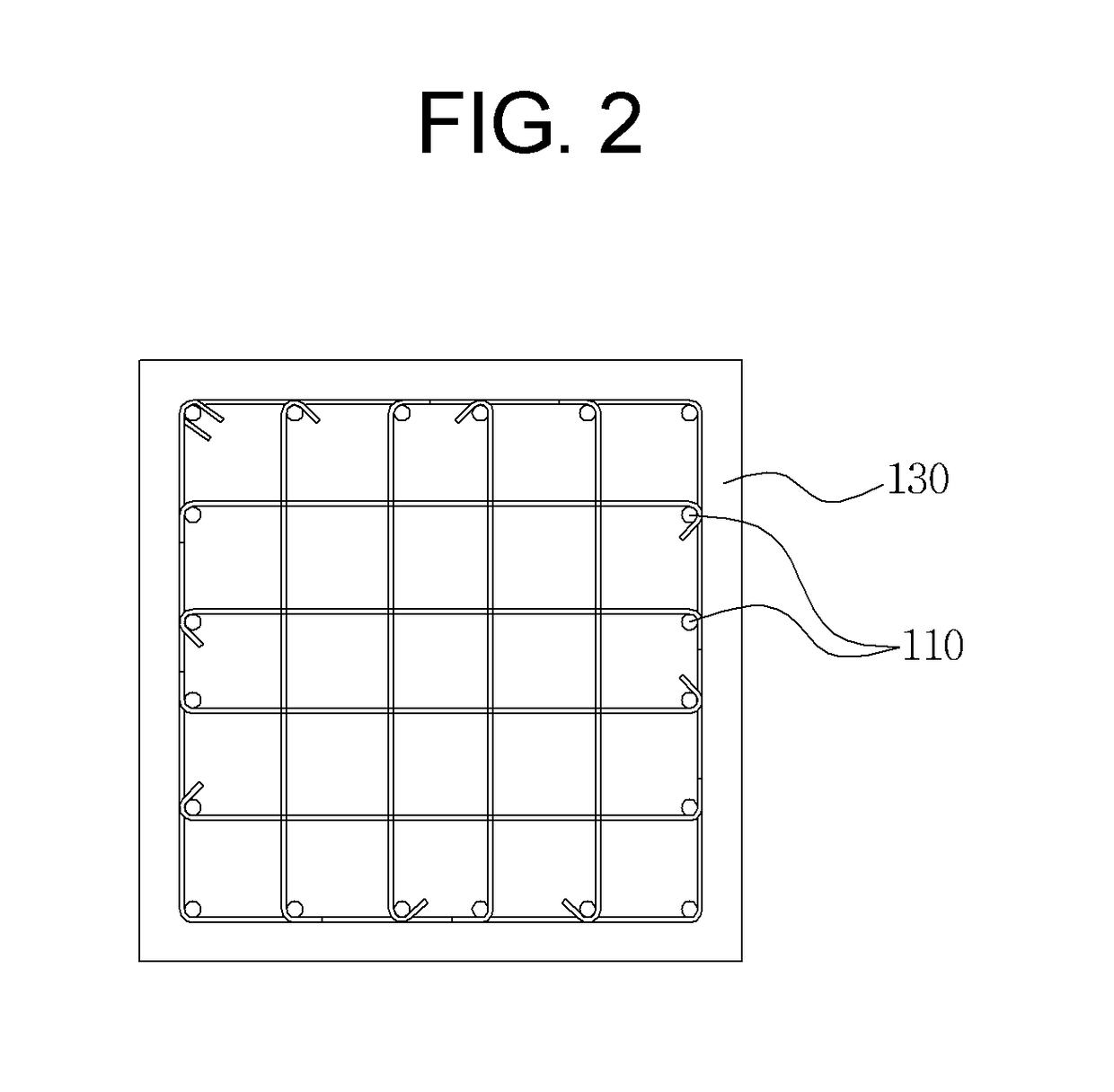

[0035]FIG. 1 is a front sectional view showing a rigid connection structure between an upper PC column and a lower PC column and a rigid connection structure of a PC beam using the same according to the present invention, FIG. 2 is a sectional view taken along the line A-A of FIG. 1, and FIG. 3 is a sectional view taken along the line B-B of FIG. 1.

[0036]FIG. 4 is an enlarged view of FIG. 1, FIG. 5 is a sectional view taken along the line D-D of FIG. 1, and (a) and (b) of FIG. 6 are top views showing an upper column plate and a lower column plate of FIG. 1.

[0037]FIG. 7 is a perspective view of FIG. 1.

[0038]A rigid connection structure between an upper PC column 100 and a lower PC column 200 according to a first embodiment of the present invention includes: the lower PC column 200 having column concrete 230, a lower column plate 270 disposed on top of the column concrete 230, and a plurality of lower column reinforcing bars 210 buriedly arranged vertically in the interior of the colu...

fourth embodiment

[0049]FIG. 16 is a sectional view showing a rigid connection structure between an upper PC column and a lower PC column and a rigid connection structure of a PC beam using the same according to the present invention, FIG. 17 is a perspective view showing the PC beam of FIG. 16, and FIG. 18 is an enlarged view of FIG. 16.

[0050]Referring analogically to the PC beam of FIG. 16, a rigid connection structure of a PC beam 300′ using the rigid connection structure between the upper PC column 100 and the lower PC column 200 according to the present invention includes: the PC beam 300′ having beam concrete 330, a beam plate 370 disposed on the side of the beam concrete 330, a plurality of beam reinforcing bars 310 buriedly arranged vertically in the interior of the beam concrete 330 to maintain the cover thickness of concrete and each having one end connected to the beam plate 370, and a beam bracket 340 having one end connected to the beam plate 370; beam upper reinforcing bars 410 arranged...

second embodiment

[0054]FIG. 11 is an enlarged front sectional view showing a rigid connection structure between an upper PC column and a lower PC column and a rigid connection structure of a PC beam using the same according to the present invention, and (a) and (b) of FIG. 12 are top views showing an upper column plate and a lower column plate of FIG. 11.

[0055]As shown in FIG. 11, a rigid connection structure between an upper PC column 100 and a lower PC column 200 according to the second embodiment of the present invention includes: the lower PC column 200 having column concrete 230, a lower column plate 270 disposed on top of the column concrete 230, and a plurality of lower column reinforcing bars 210 buriedly arranged vertically in the interior of the column concrete 230 to maintain the cover thickness of concrete and having upper ends penetrated into the lower column plate 270 in such a manner as to be exposed to the outside; and the upper PC column 100 having column concrete 130, an upper colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com