Spring and apparatus for its use

a technology of spring and apparatus, applied in the direction of hose connection, machine/engine, coupling, etc., can solve the problems of damage to vital aircraft components, vibration in the exhaust system, and stress cracking in the walls of the exhaust system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

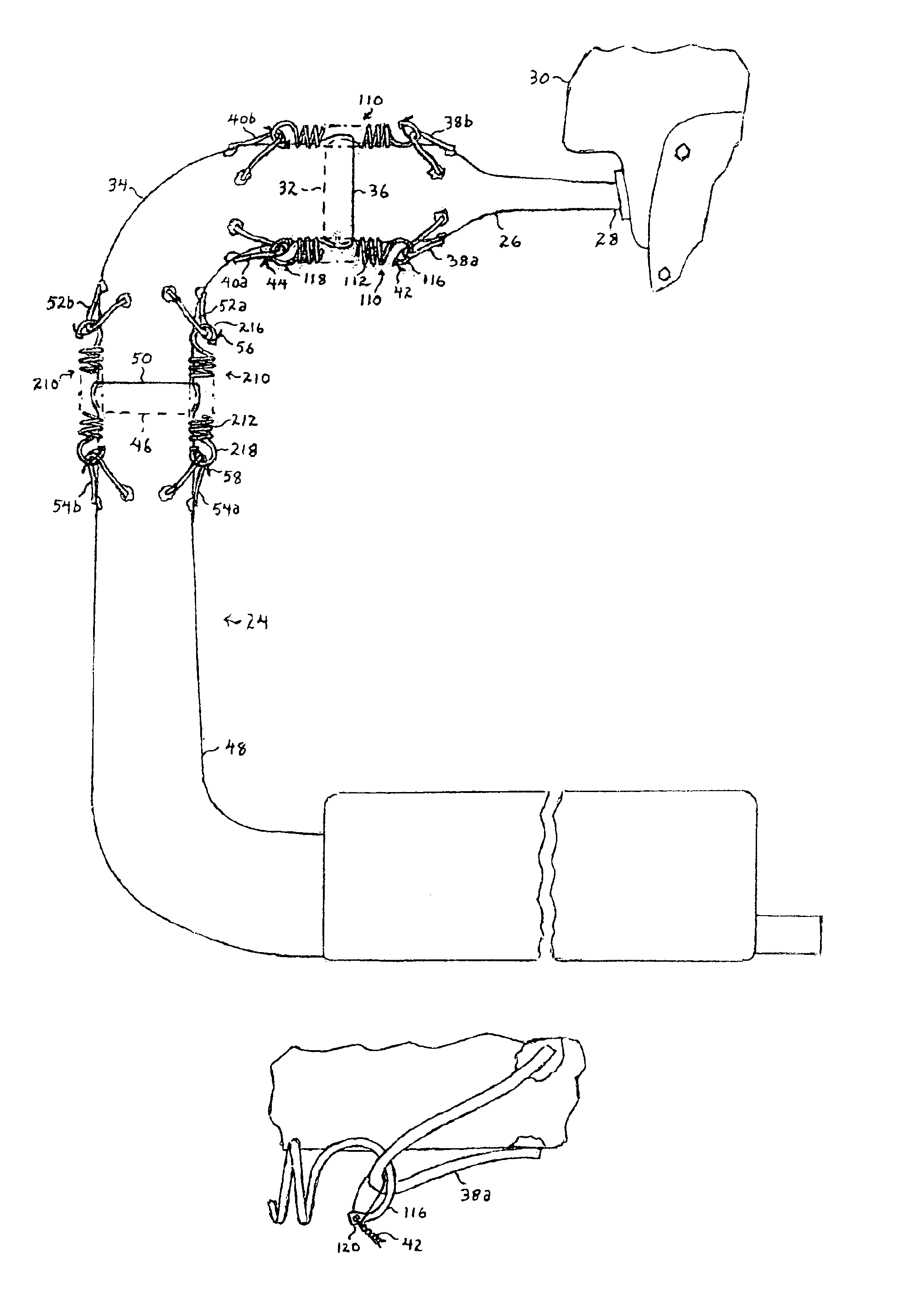

Referring to FIG. 1, spring 10 is comprised of a wire (i.e. of a high carbon spring steel) which includes an elastic, coiled central portion 12 having a longitudinal axis 14. Coiled central portion 12 is preferably helically wound so as to have multiple and adjacent convolutions that contact one another when the coiled central portion is in its relaxed state as shown. Spring 10 further includes opposing end portions formed as hooks 16 and 18. Hook 16 terminates in an end 20 having a hole therethrough, and hook 18 similarly terminates in an end 22 also having a hole therethrough. Each of hooks 16 and 18 is curved so as terminate in its corresponding end adjacent to but longitudinally spaced from coiled central portion 12. As shown with respect to two convolutions of coiled central portion 12 that are partially broken away, the wire of spring 10 is preferably round in cross section, except for ends 20 and 22 which are flattened. Each flattened end and the remainder of the correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com