Composite false-proof safety thread and its production method, false-proof paper applying the safety thread

A manufacturing method and security thread technology are applied in the field of anti-counterfeiting paper, which can solve the problems of poor stability of machine-readable electromagnetic characteristics, inability to realize three-line anti-counterfeiting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

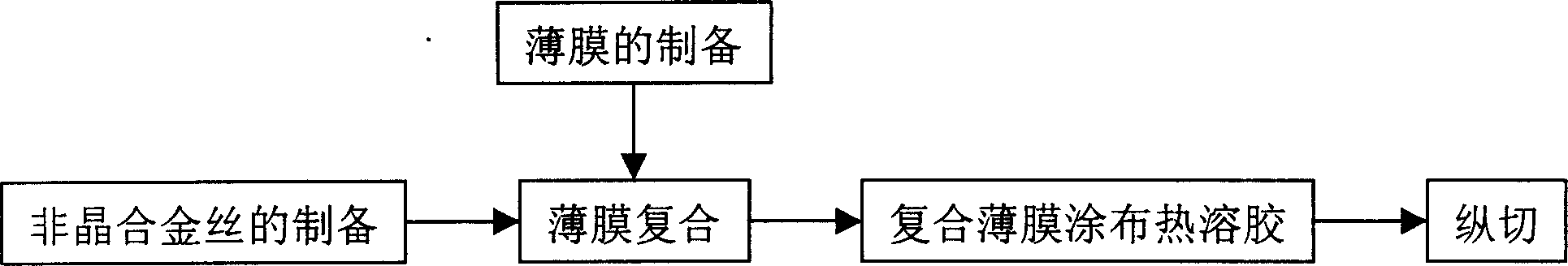

Method used

Image

Examples

Embodiment Construction

[0036] The specific characteristic performance of the present invention is further described by the following examples and accompanying drawings.

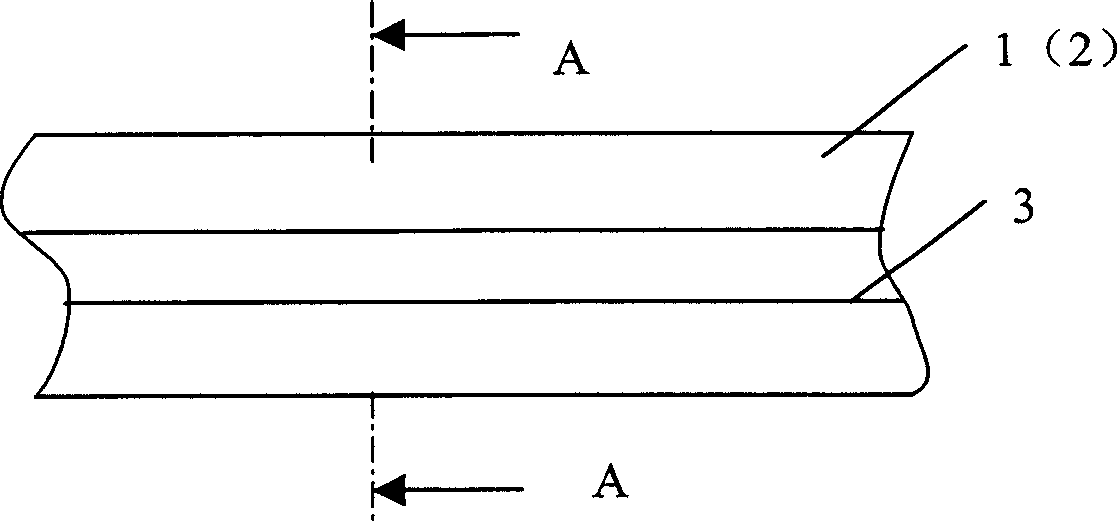

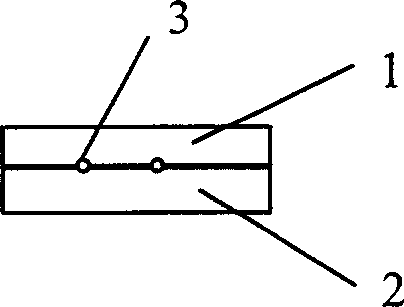

[0037] See figure 1 , figure 2 as shown,

[0038] The composite anti-counterfeiting safety thread 5 of the present invention comprises film layers 1, 2, and amorphous alloy wire 3, and film layer 1, 2 comprises two layers at least, namely upper and lower two layers, and amorphous alloy wire 3 is positioned at film layer 1, 2 between.

[0039] The amorphous alloy wire 3 is amorphous and has electromagnetic properties.

[0040] Amorphous anti-counterfeiting silk coated or dyed by some anti-counterfeiting material is glued between two layers of film. The film layers 1 and 2 may both be polymer film layers, or a polymer film layer and a laser holographic film layer may be used, and patterns are printed on the film layers.

[0041] The film layer is coated or printed with magnetic and optical specific powder anti-counterfeiting ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com