False proof thin film and producing method thereof

A film and film layer technology, which is applied in the field of anti-counterfeiting films with invisible patterns and its production, can solve the problems of reducing the reliability of anti-counterfeiting and being easily imitated, and achieve the effects of strong anti-counterfeiting strength and enhanced visual effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

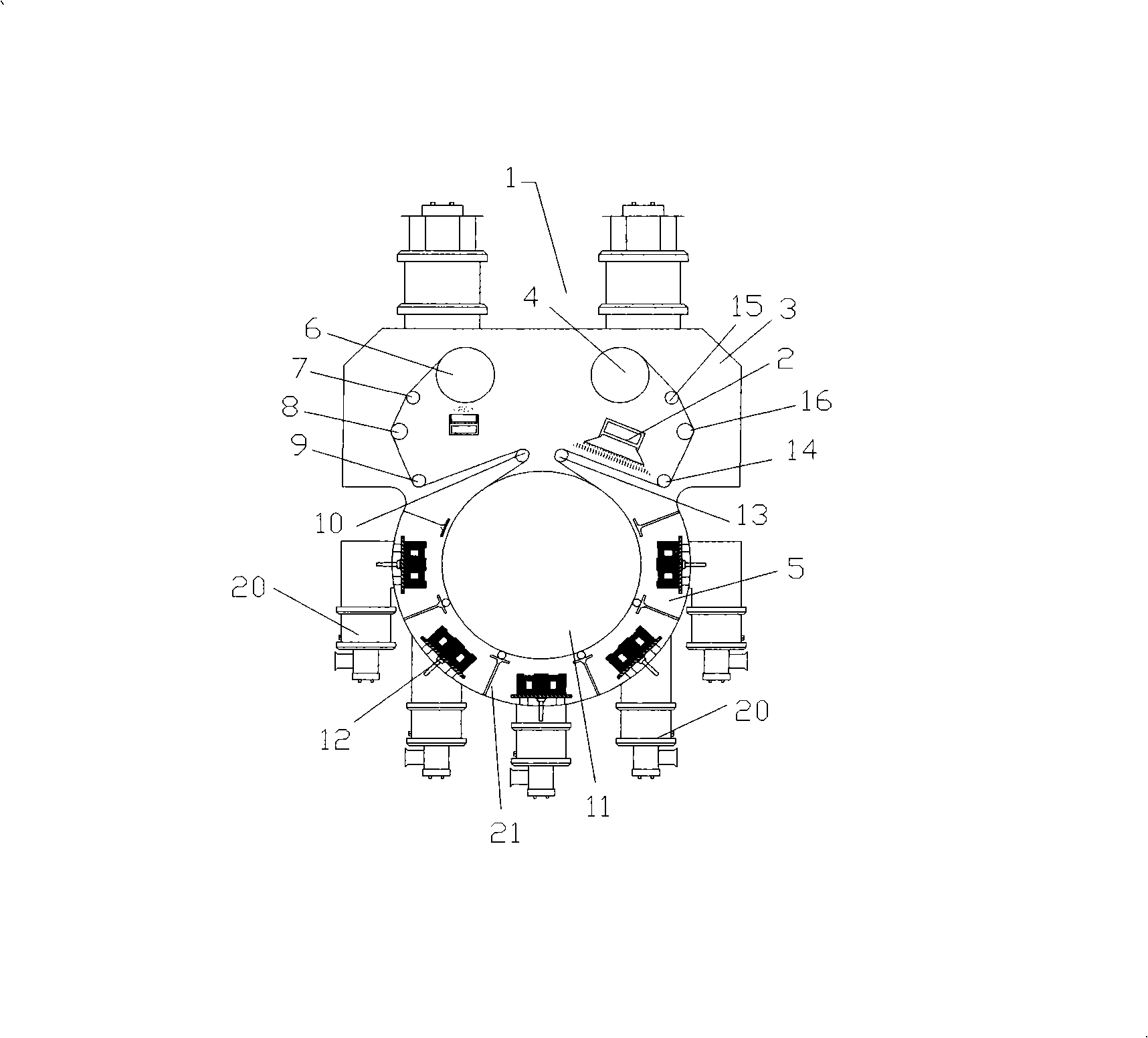

[0039] figure 1For making the device schematic diagram of anti-counterfeit film of the present invention, comprise vacuum winding coating machine 1 and pulse laser source 2, wherein, pulse laser source 2 is arranged in vacuum winding coating machine 1, is installed in the winding roller of winding room 3 4 and the vacuum coating chamber 5 between the last film deposition chamber. The production process of the anti-counterfeiting film in this device is as follows: first, the flexible substrate of the required coating is continuously unrolled by the unwinding roller 6 in the vacuum winding chamber 3, and passed by the corresponding guide rollers 7 and 8, tension Roller 9 and pressing roller 10 convey described flexible base material to coating chamber 5, and cooling roller 11 is arranged in the middle of this coating chamber 5, and five sputtering target chambers 12 are arranged on the edge of vacuum coating chamber 5 around cooling roller 11 The corresponding target sources in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com