Portable tool for replacing tension wire shockproof hammer in power cut

A shock-proof hammer, portable technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of high energy consumption, low work efficiency, cumbersome procedures, etc., and achieve the effect of reducing labor intensity, easy operation, and reducing work procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

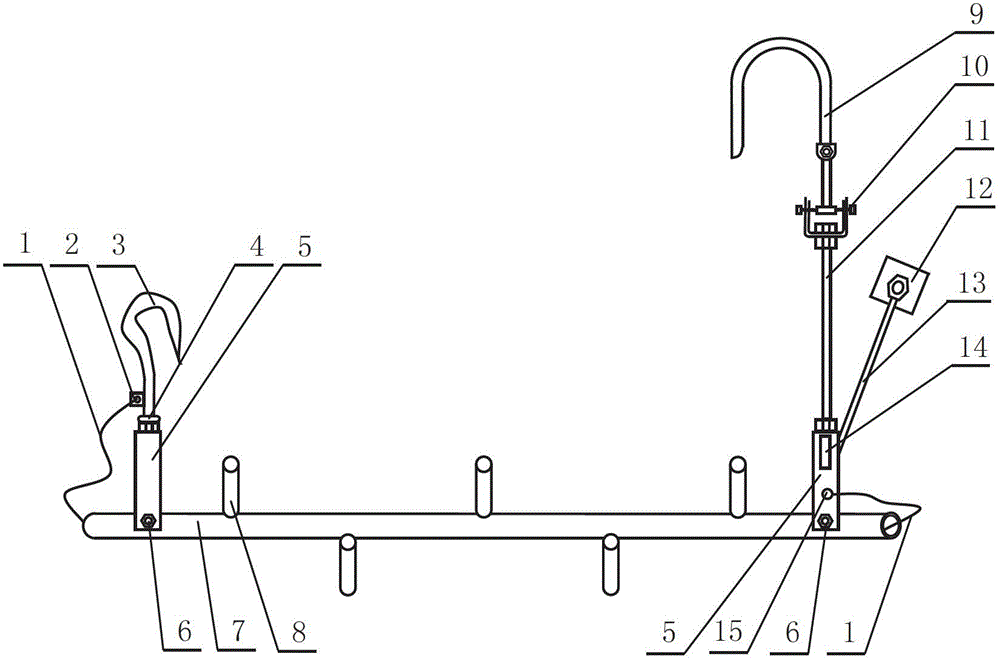

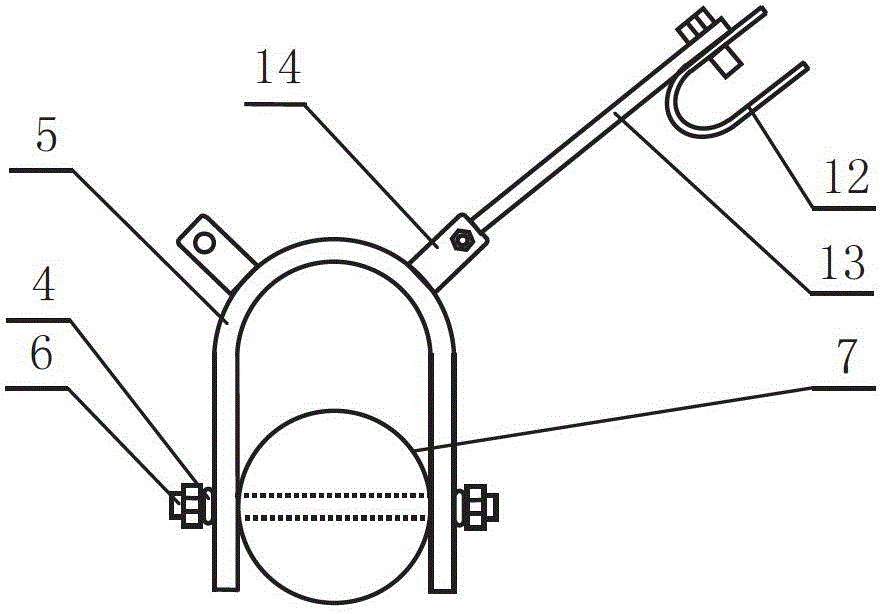

[0018] Such as figure 1 As shown, the present invention includes a main insulating tube 7, a universal hook 3 on the wire side, a universal hook 9 on the cross-arm side, a U-shaped connecting plate 5, a through-center fixing bolt 6, and the like.

[0019] Five secondary insulating pipes 8 are arranged on the main insulating pipe 7 to form a centipede ladder. The two ends of the main insulating tube 7 are connected to the U-shaped connecting plates 5 through the through-hole fixing bolts 6 near the ends, and the spring washers 4 are installed before the nuts are installed on both sides of the through-hole fixing bolts 6 .

[0020] The U-shaped connecting plate 5 at the left end is connected to the lead side universal hook 3 by a nut and a spring washer 4, and the lower end of the lead side universal hook 3 is provided with a lead side security line connecting plate 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com