Check disk for optical data storage disk manufacturing

a technology for optical data storage and disk manufacturing, which is applied in the direction of optical articles, domestic applications, record carriers, etc., can solve the problems of affecting the production cycle, affecting the production quality of optical data storage disks, and destroying the masters in general, so as to avoid creation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

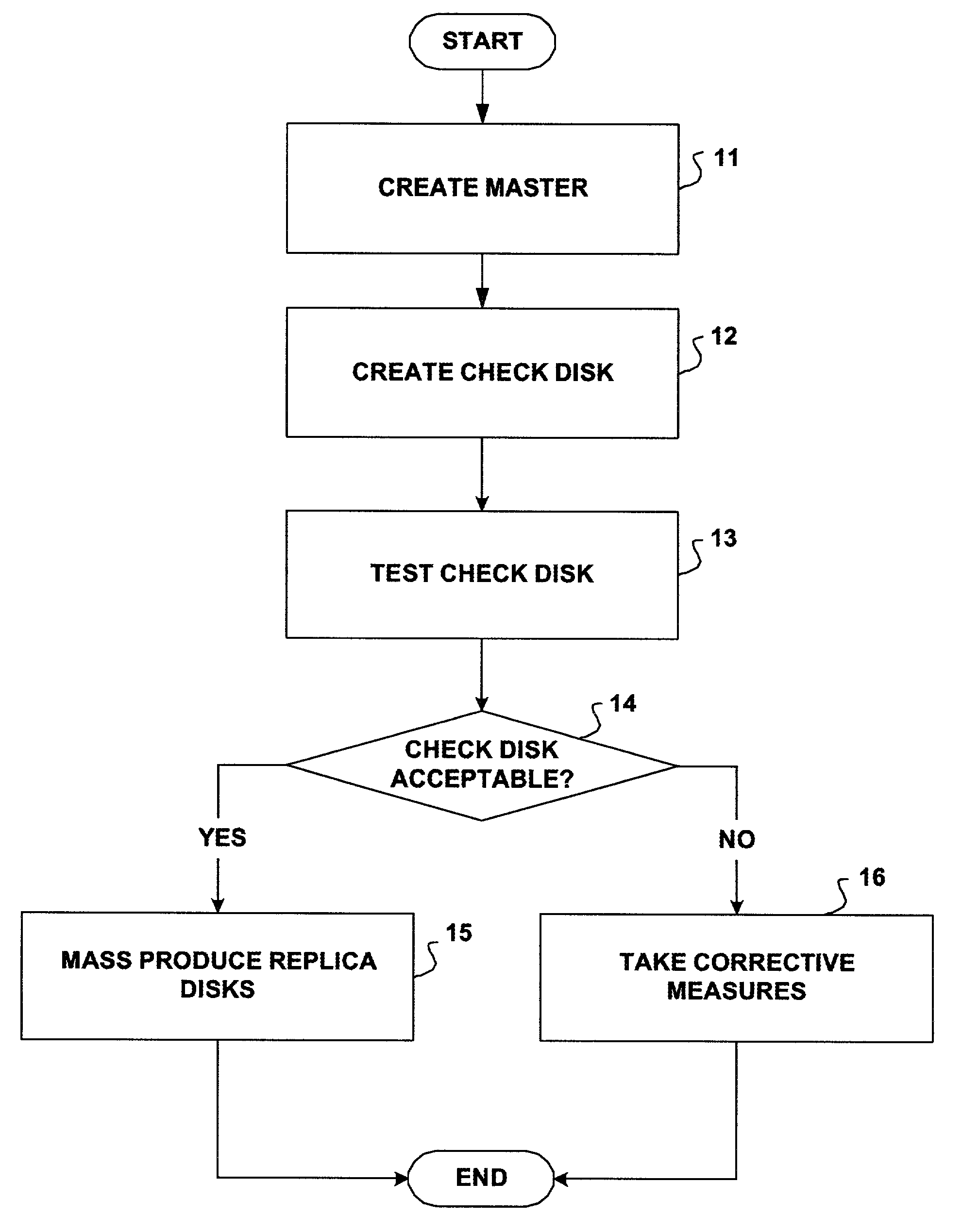

[0023]FIG. 1 is a flow diagram according to an embodiment of the invention. As shown, a master is created (11). Many mastering techniques are known in the art, and typically involve coating a photoresist on a master substrate, exposing the coated master substrate to expose a photoresist pattern, and then removing the photoresist in the exposed or non-exposed regions. Mastering techniques are used to define the pattern (or the inverse of the pattern) that is eventually replicated into optical data storage disks.

[0024]After the master has been created, a check disk is created from the master without destroying the master (12). More specifically, the creation of the check disk occurs prior to the creation of mass production replication tools, such as metal stampers, that can be used in an injection molding process or a rolling bead process. As described in greater detail below, the process of creating a check disk may involve coating a master surface with a release layer and coating a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap