Outlet box knockout

a technology for outlet boxes and knockouts, which is applied in the direction of caps, liquid handling, transportation and packaging, etc., can solve the problems of difficult arrangement and difficulty in molding the knockouts in a manner, and achieve the effect of minimizing the possibility of other knockouts and easy knockout removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

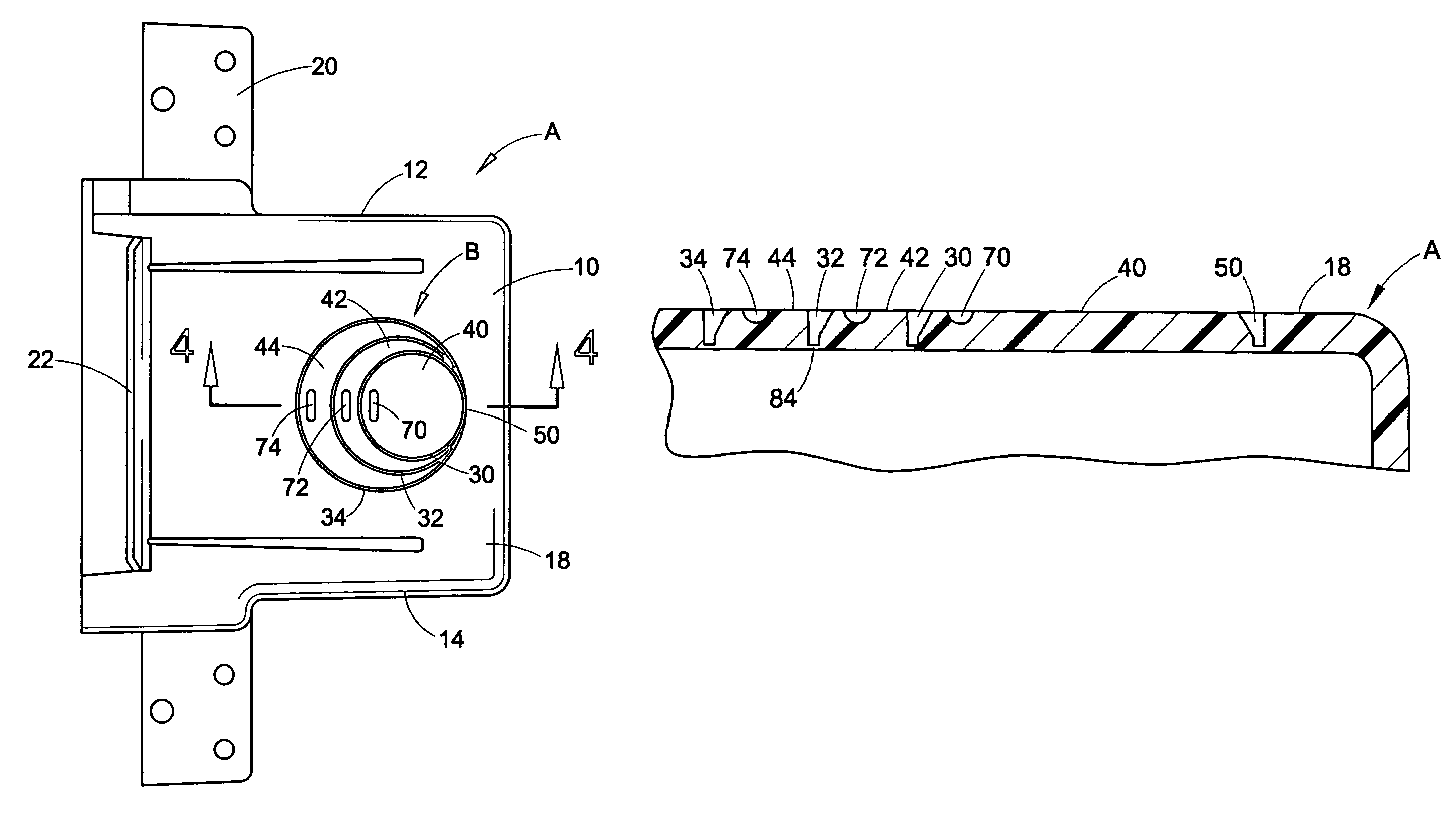

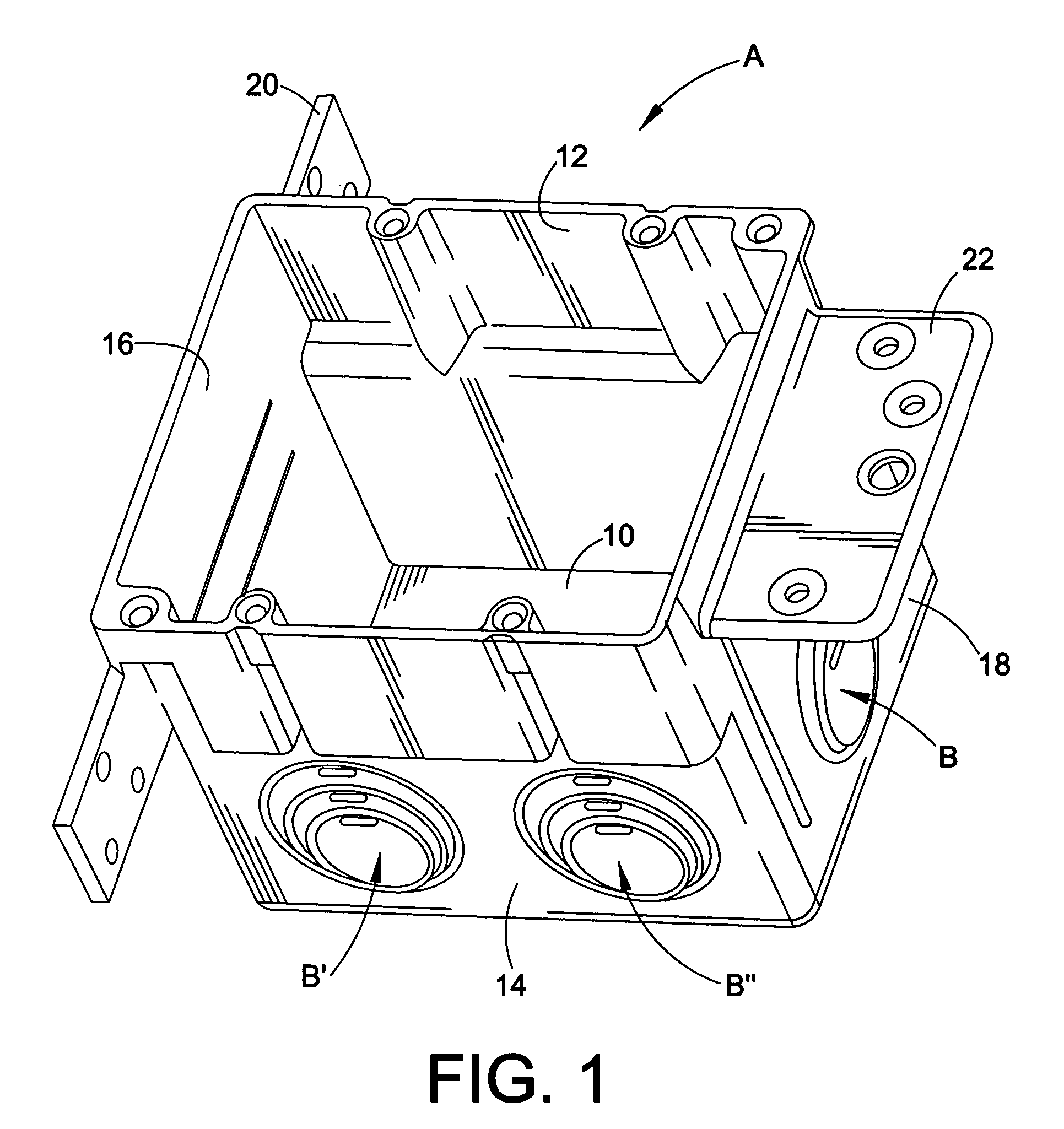

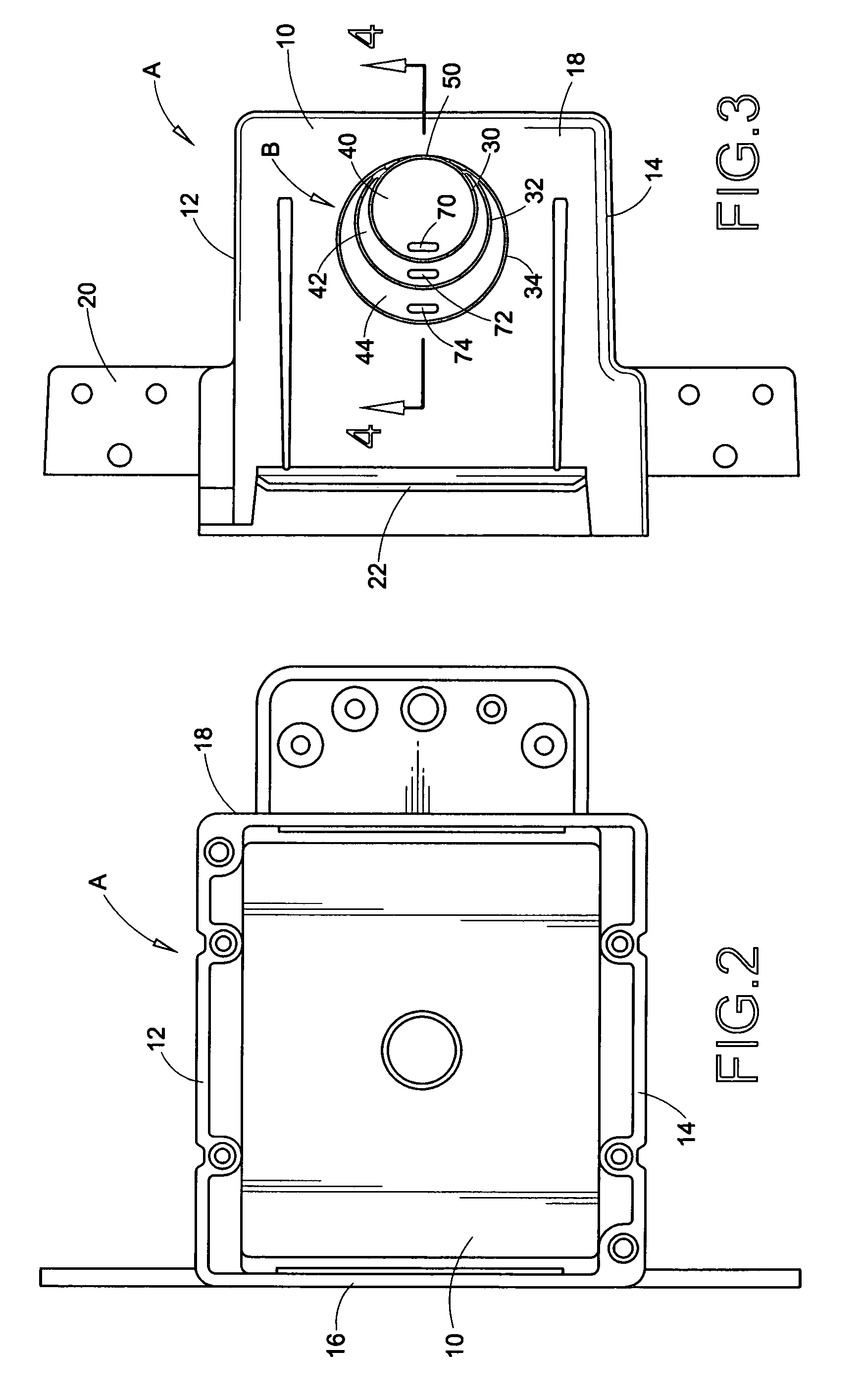

[0015]Referring now to the drawing, wherein the showings are for purposes of illustrating a preferred embodiment of the invention only and not for purposes of limiting same, FIG. 1 shows an electrical outlet box molded of plastic material such as, but not necessarily limited to, PVC or polycarbonate. Box A has a bottom wall 10, opposite side walls 12, 14 and opposite end walls 16, 18. Box A has an open front end opposite from bottom wall 10. Although a two gang box is illustrated in the drawings, it will be appreciated that the invention can be used with single gang boxes as well as with boxes, enclosures and housings of many other types. Box A has mounting flanges 20, 22 for attaching same to wall studs or to joists.

[0016]FIG. 3 shows a knockout arrangement B that is molded into wall 18. It will be recognized that the knockout arrangement of the present application may be provided in one or more of the box walls and that some box walls may have more than one knockout arrangement. F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com