Spring loaded attachment mechanism for camera and base

a technology of spring loaded attachment and camera, which is applied in the field of spring loaded attachment mechanism for supporting a camera or a camera base, can solve the problems of accidental detachment, difficult proper attachment, and many of the current mechanisms are not backwards compatible with standard camera tripod attachment pins, and achieves low attachment force and high detachment force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

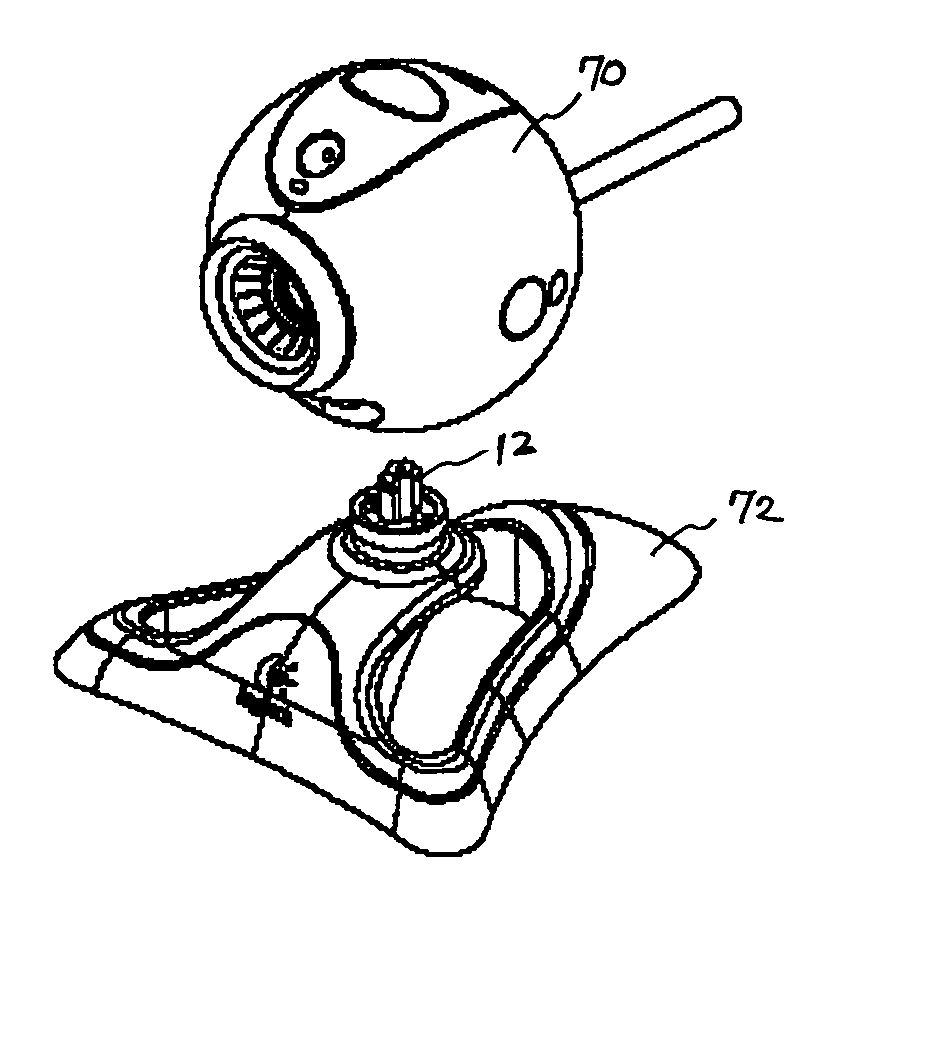

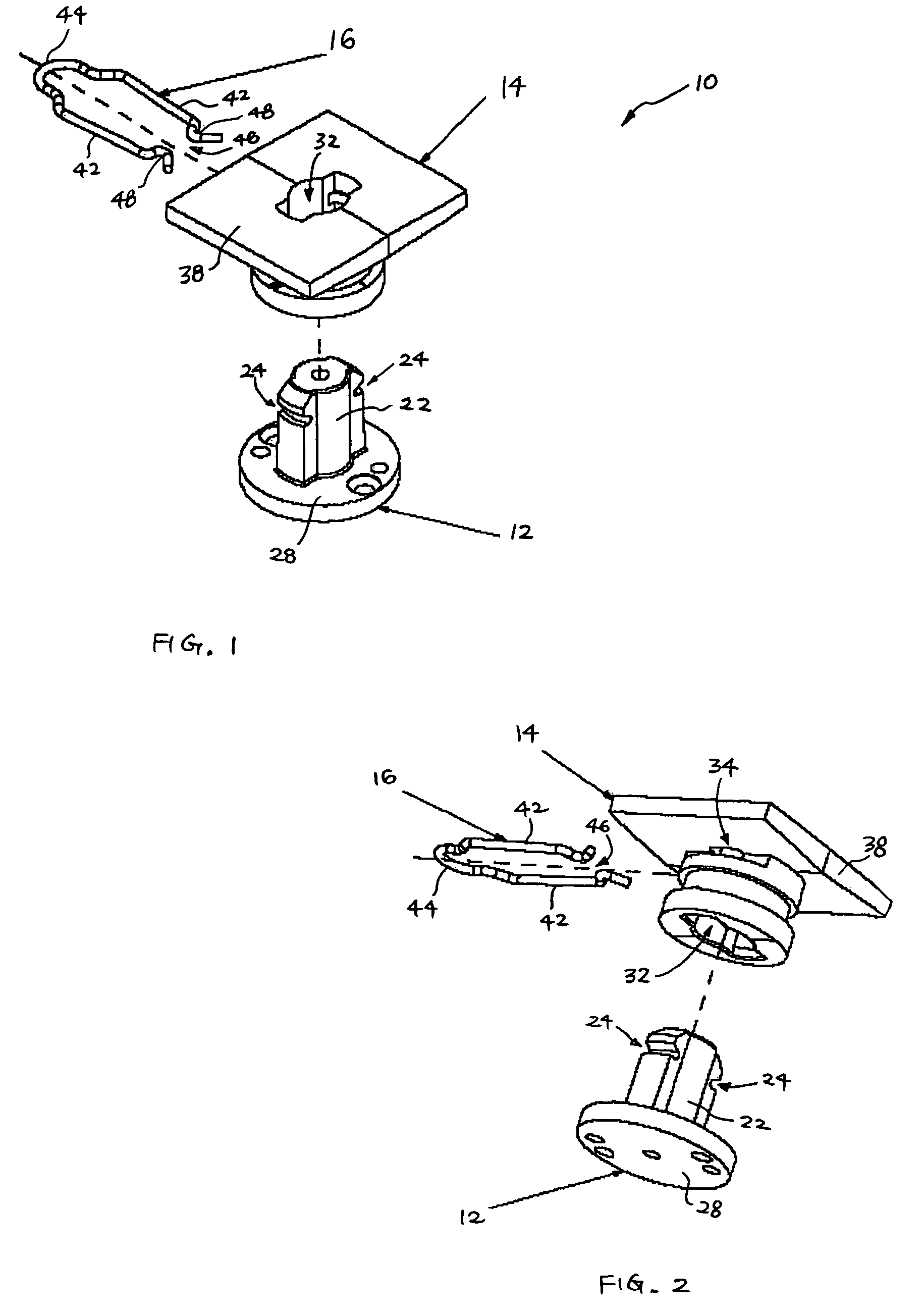

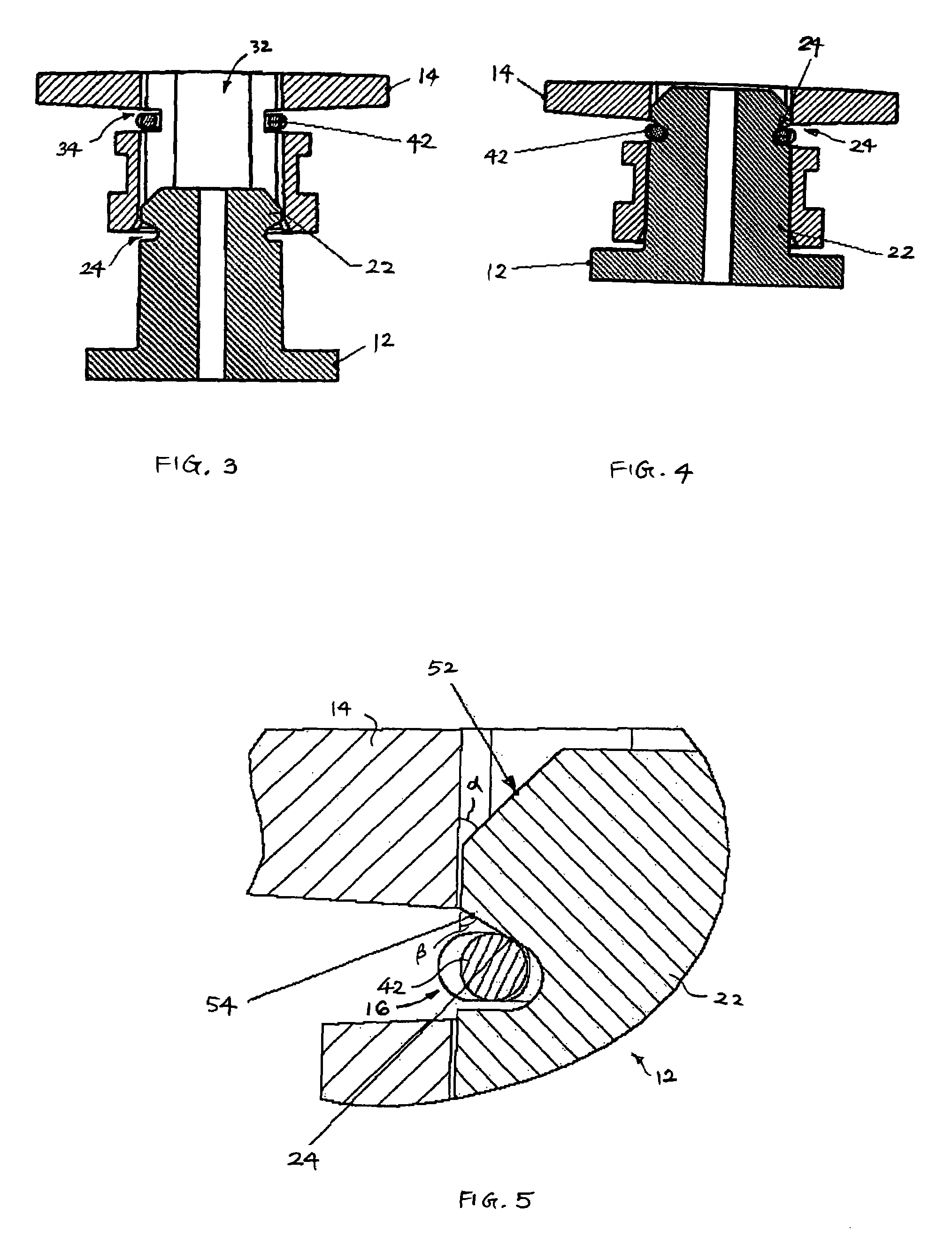

[0019]FIGS. 1 and 2 show a camera attachment apparatus 10 including an attachment pin 12, an attachment socket 14, and a resilient member such as a spring 16. The attachment pin 12 has a post 22 with a longitudinal axis, preferably with a large key feature. A pair of seats 24 are provided on opposite sides of the post 22. The seats 24 are formed as external slots or grooves on the post 22 in the embodiment shown. The attachment pin 12 may further include a base 28 which may be used to connect the attachment pin 12 to a camera support or the like. The attachment socket 14 includes an aperture 32 extending in a longitudinal direction to receive the post 22 of the attachment pin 12. The attachment socket 14 includes a pair of cutouts 34 that are disposed laterally on opposite sides and correspond to the pair of seats 24 of the post 22. The attachment socket 14 may include a platform 38 which may be used to connect the attachment socket 14 to the body of a camera or camera base or the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com