Deployable containment system

a containment system and modular technology, applied in the field of secondary containment systems, can solve the problem of one strut engagement and achieve the effect of reducing weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

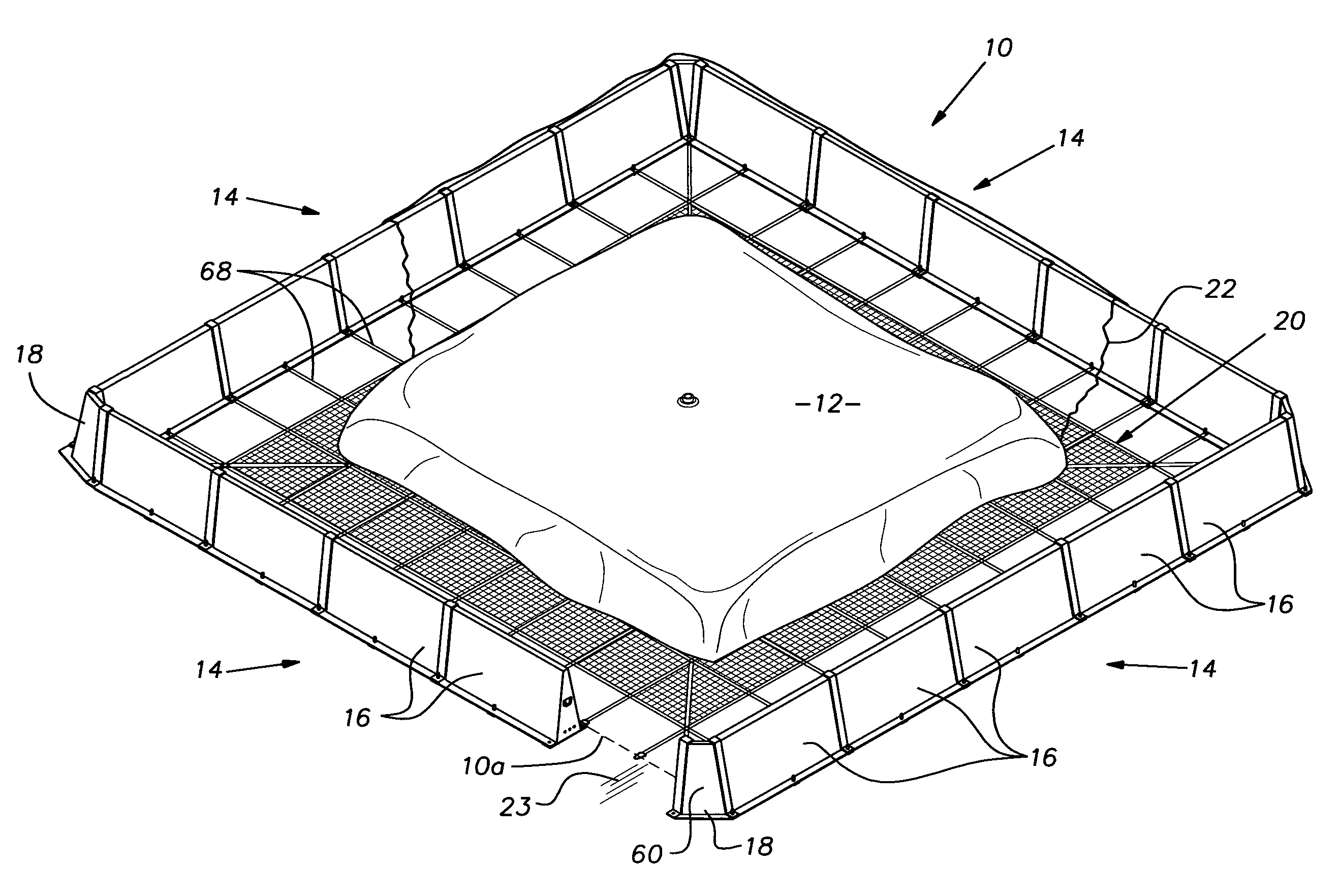

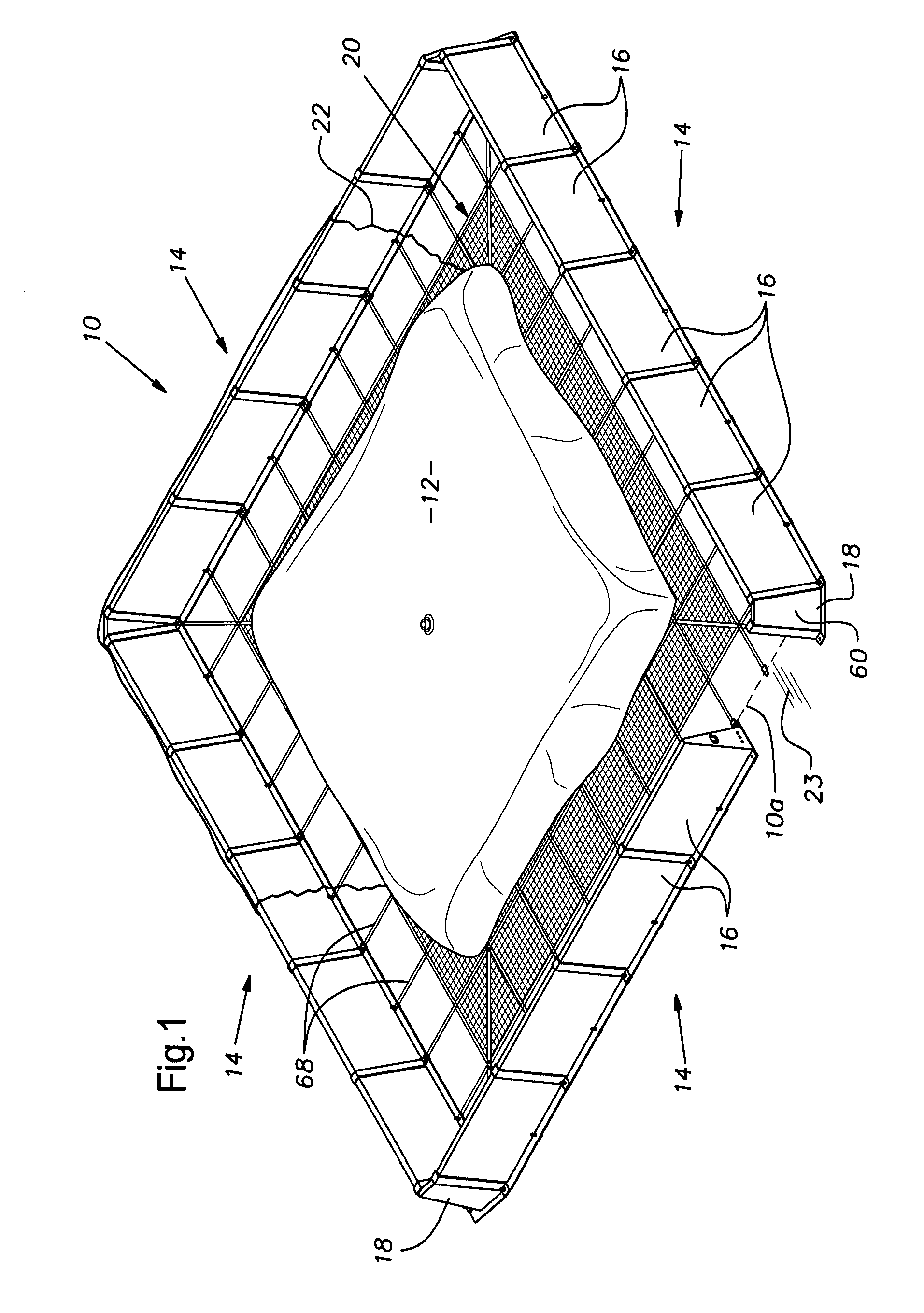

[0022]A closed barrier or dike assembly 10 surrounding a primary container 12 is shown in FIG. 1. The primary container 12 is a flexible bladder construction that may contain a fuel to be isolated from the environment in case of container failure or as required by environmental regulations.

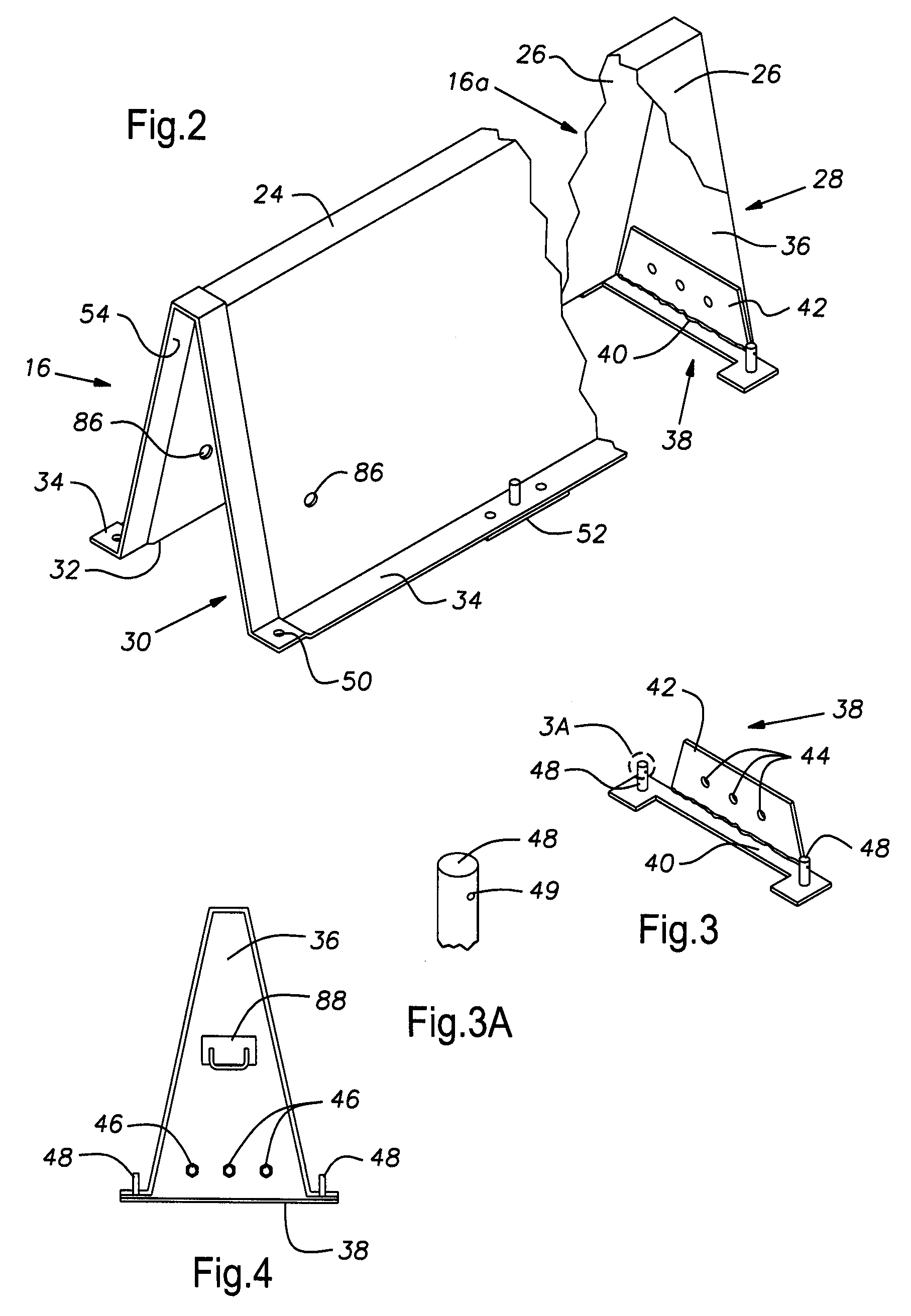

[0023]The dike assembly 10 has a square configuration provided by opposed dike walls 14 formed by interlocked strut members 16 extending between and interlocked with corner members 18. An alignment web 20 has extremities extending along an interior perimeter 10a of the dike assembly 10 and secures the members 16 and 18 together as further explained below.

[0024]For purposes of fluid containment, a fluid impermeable barrier film or sheet 22 is disposed between the primary container 12 and the web 20, along the substratum 23 and over the dike walls 14. The sheet 22 may be secured in place by connection to the dike walls or loosely draped over the dike walls and / or optionally secured to the substratum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com