Impact absorbing striking tool

a technology of impact absorption and striking tools, which is applied in the field of striking tools, can solve the problems of not being aware of any such devices, not being able to employ hammers of common designs, and applicants being unaware of such devices, so as to achieve the effect of effectively impacting a target object and sufficient mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

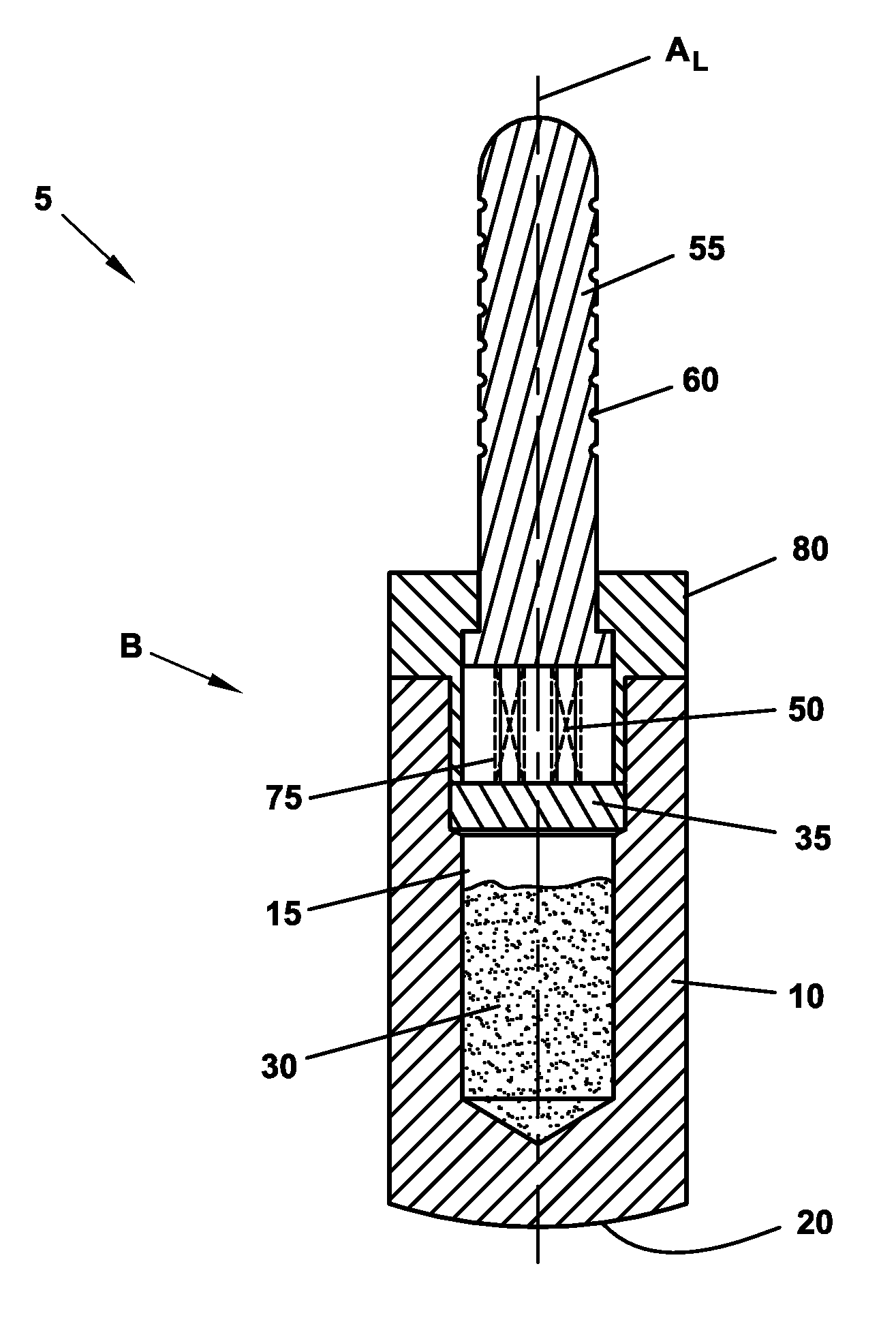

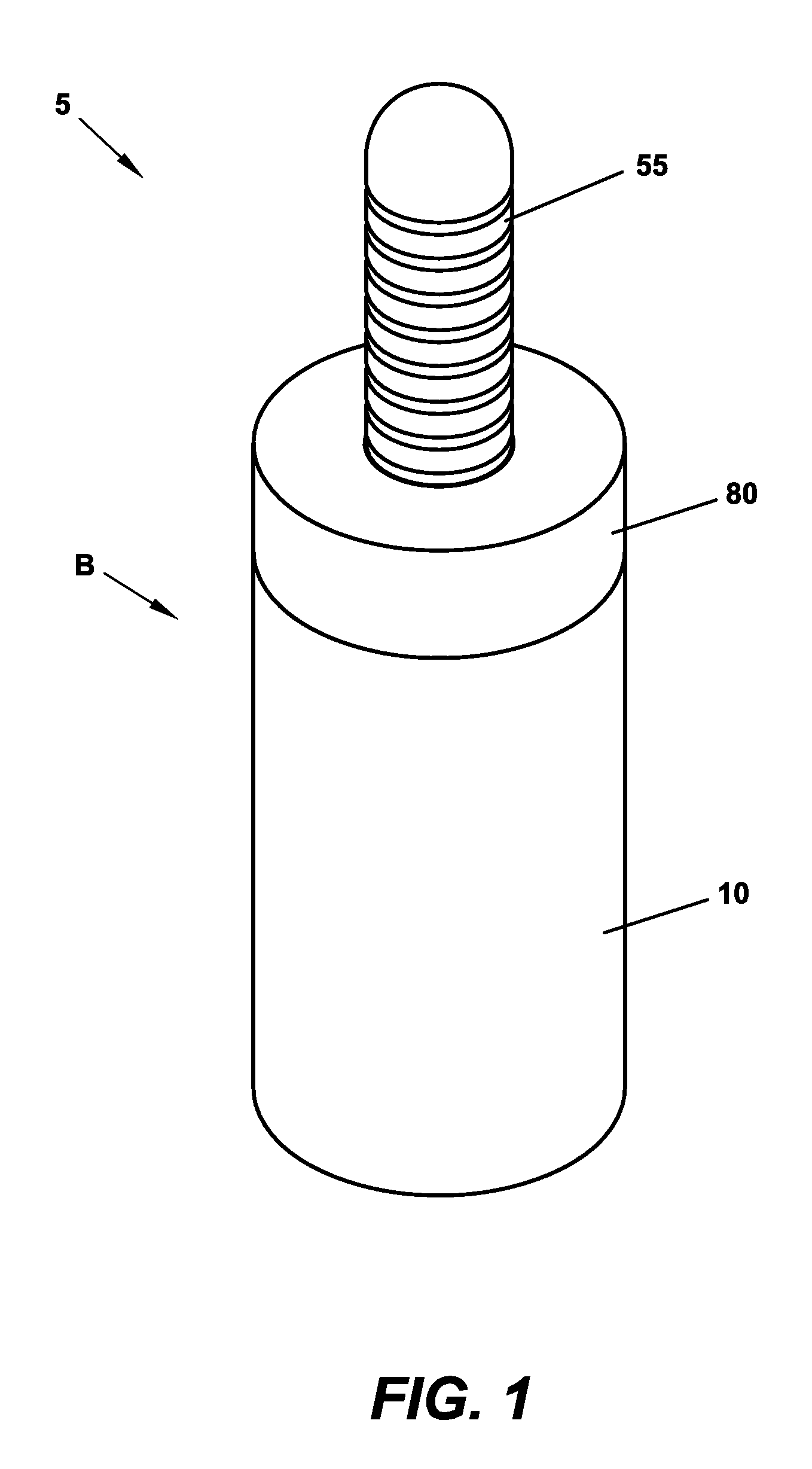

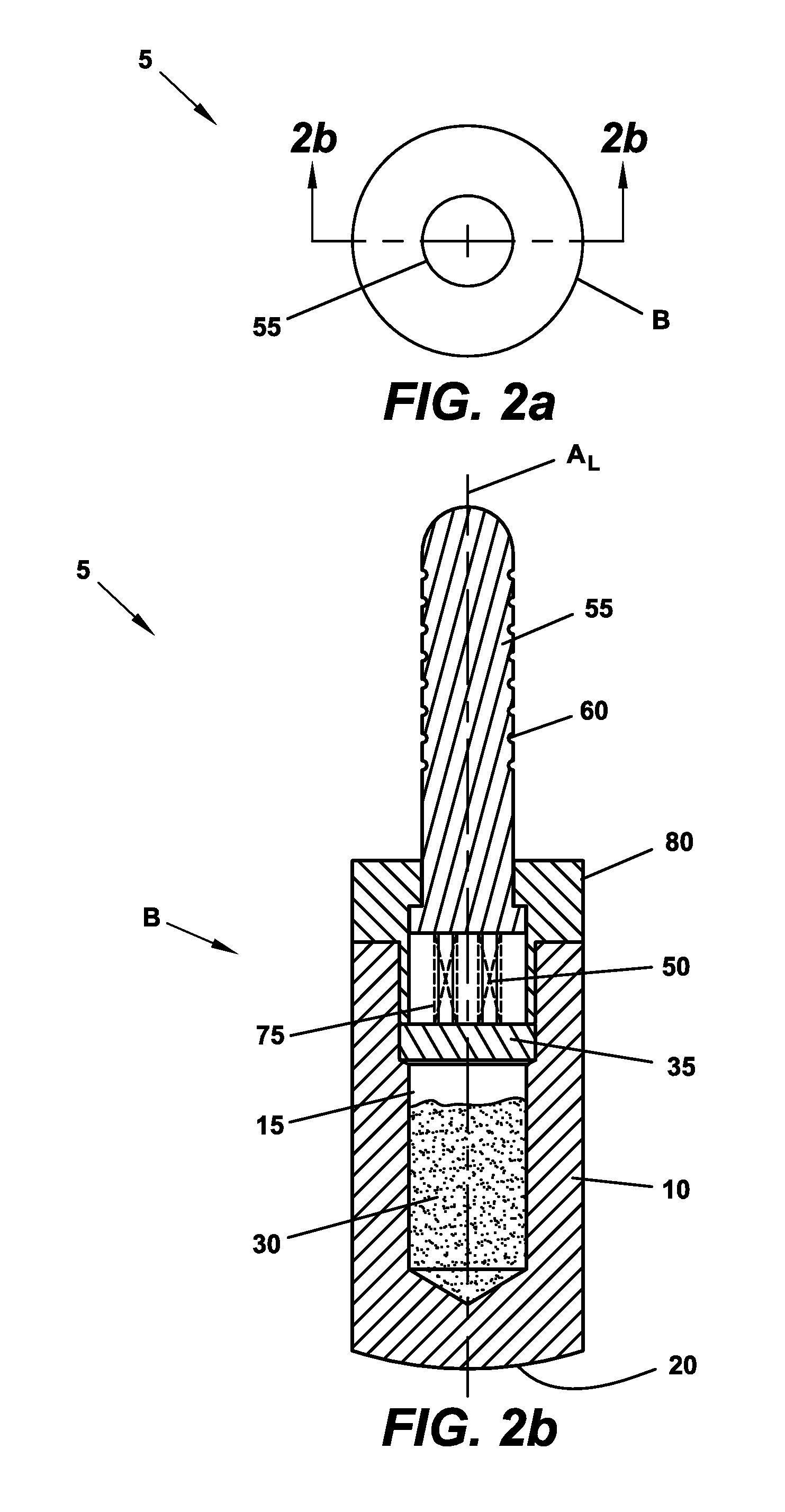

[0019]One exemplary embodiment of an assembled impact absorbing striking tool 5 of the present invention can be observed in FIGS. 1-2b. As shown, the impact absorbing striking tool 5 includes a body portion B having a forward, impacting section 10, and a rear cap 80. The impacting section 10 of this particular embodiment comprises a substantially cylindrical body having a closed, striking end 10a, and an open, rearward end 10b. Non-cylindrical shapes are also possible. The impacting section 10 is also shown to include an axial bore that extends from the open end 10b toward the closed end 10a thereof so as to form a cavity 15 within the impacting section. The cavity 15 terminates at some distance from the exterior striking surface 20 of the impacting section 10. A rearward end of the cavity 15 terminates in a threaded counterbore 25 that extends inward from the open end 10b of the impacting section 10.

[0020]Preferably, but not necessarily, the cavity 15 is at least partially filled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com