Illuminating brick

a technology of illumination bricks and bricks, applied in the field of illumination bricks, can solve the problems of insufficient illumination of the entire surface, and may not be practical or desirable to be positioned adjacent to the paved surface of lighting fixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

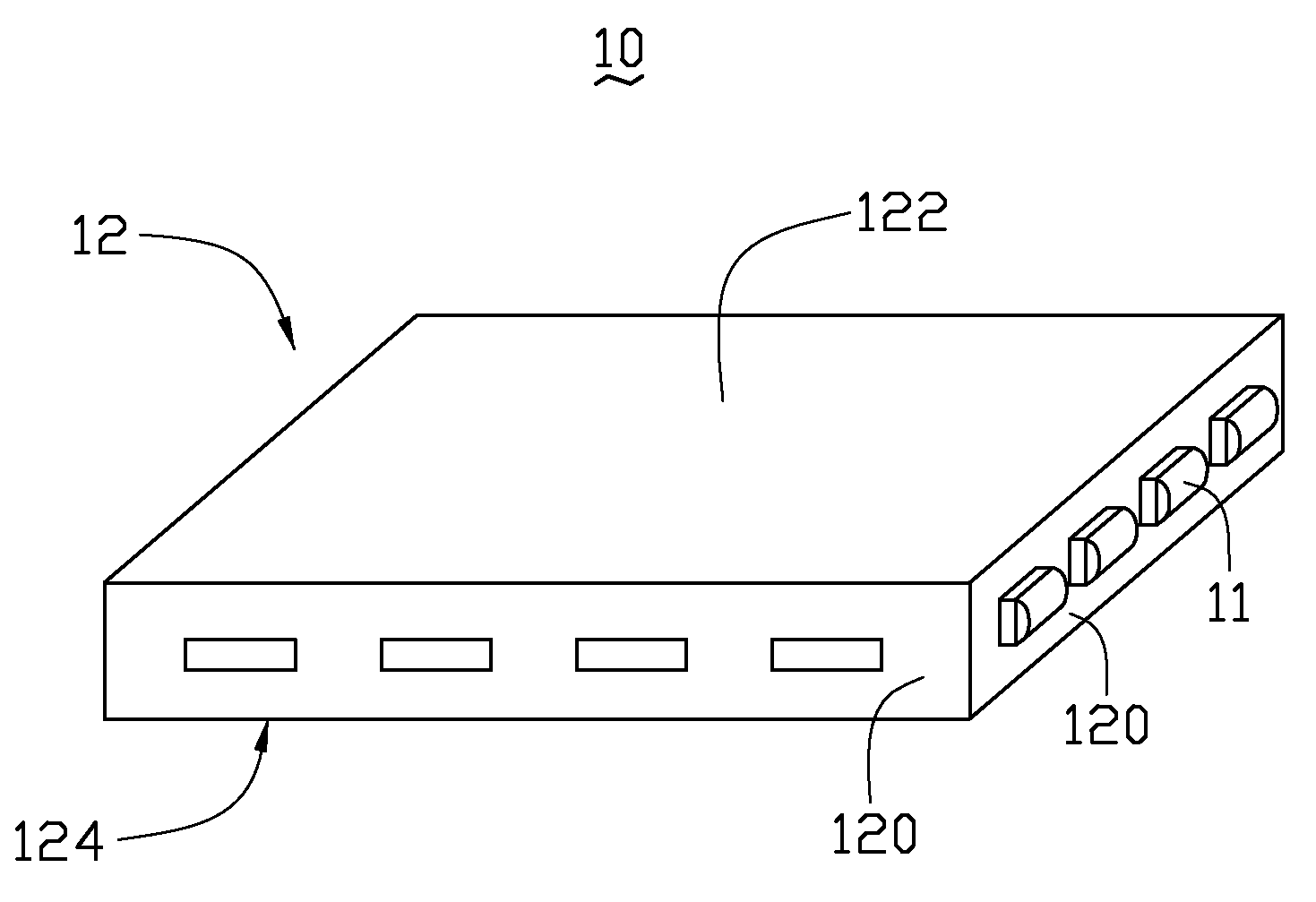

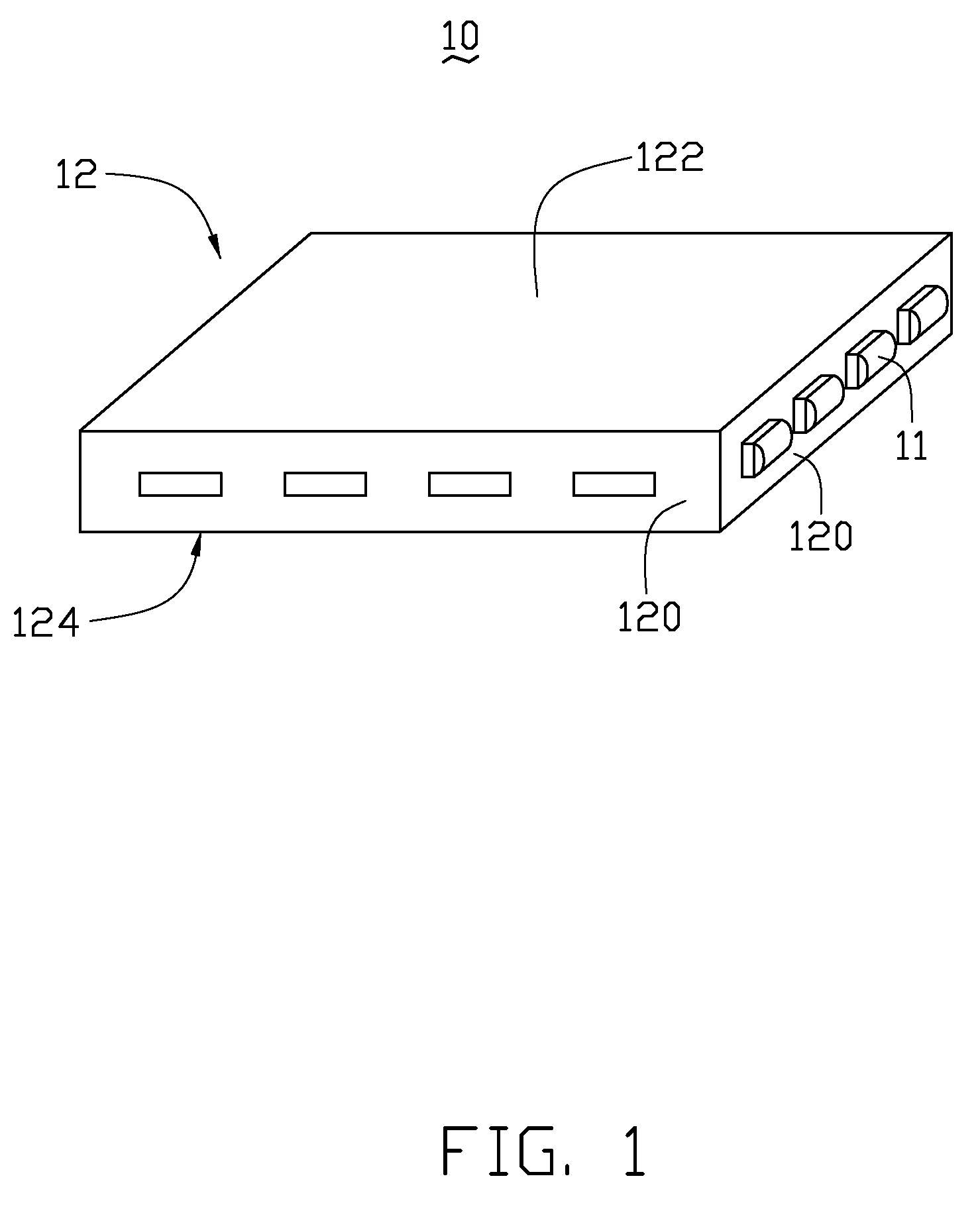

[0013]Referring to FIG. 1, an illuminating brick 10 can be used as unit pavers, stepping stone, ceramic tile etc. and comprises a brick 12 and a plurality of LED components 11 as light sources embedded in the brick 12.

[0014]The brick 12 optically coupling with the LED components 11, is made of transparent material such as tempered glass, polymethylmethacrylate, poly carbonate and silicone etc. The brick 12 can be made in any variety of shapes and sizes. In the present embodiment, the brick 12 is cuboid-shaped and includes a top face 122, a bottom face 124 opposite to the top face 122, and four lateral sides 120. In the first exemplary embodiment, the bottom face 124 is configured for being disposed on a relatively flat surface such as graded soil. The LED components 11 are embedded in and optically coupled to at least one of the four lateral sides 120. Light emitted by the LED components 11 diffuses into the brick 12 through the corresponding lateral side 120 and is then internally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com