Flow-through pressure sensor apparatus

a flow-through pressure sensor and flow-through technology, which is applied in the direction of fluid pressure measurement by mechanical elements, instruments, measurement devices, etc., can solve the problems of limiting the frequency response of the device, the dead volume may interfere with the smooth, laminar flow of fluid, and the pressure connection configuration available on most pressure sensors is ‘dead-ended’. , to achieve the effect of reducing the dead space of the flow tube, minimizing the chance of dust or similar contaminants becoming trapped in the apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]The particular values and configurations discussed in these non-limiting examples can be varied and are cited merely to illustrate at least one embodiment and are not intended to limit the scope thereof.

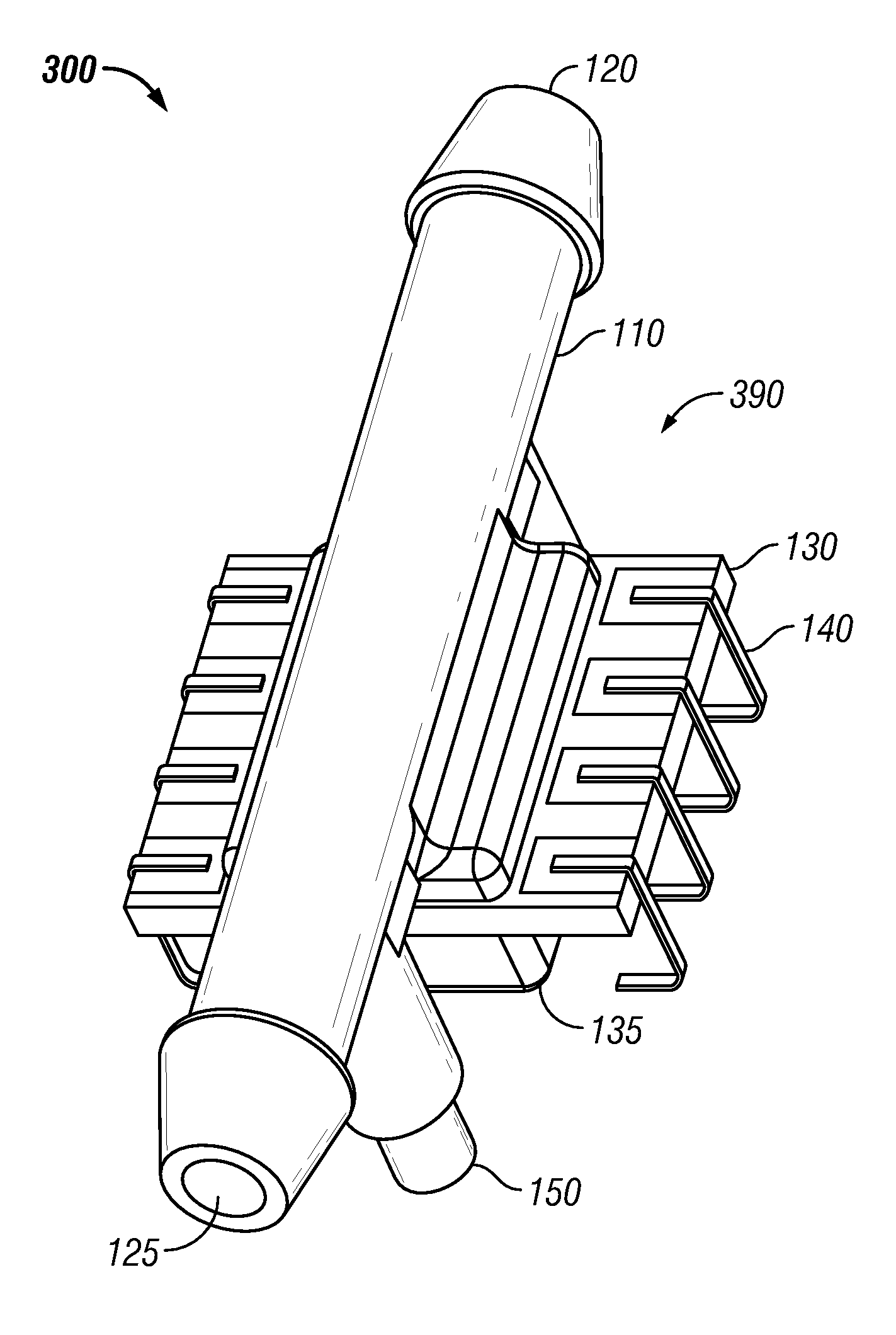

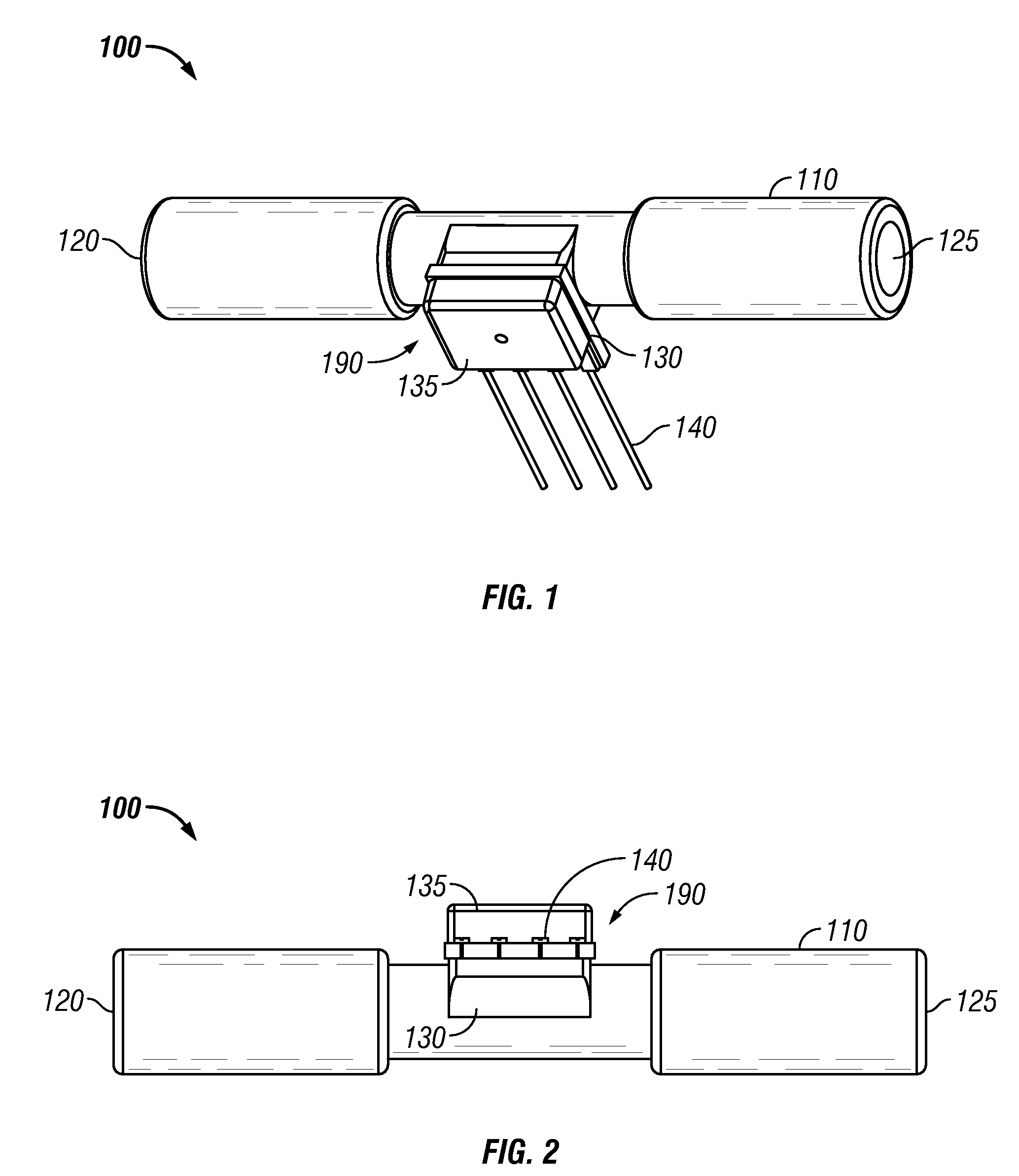

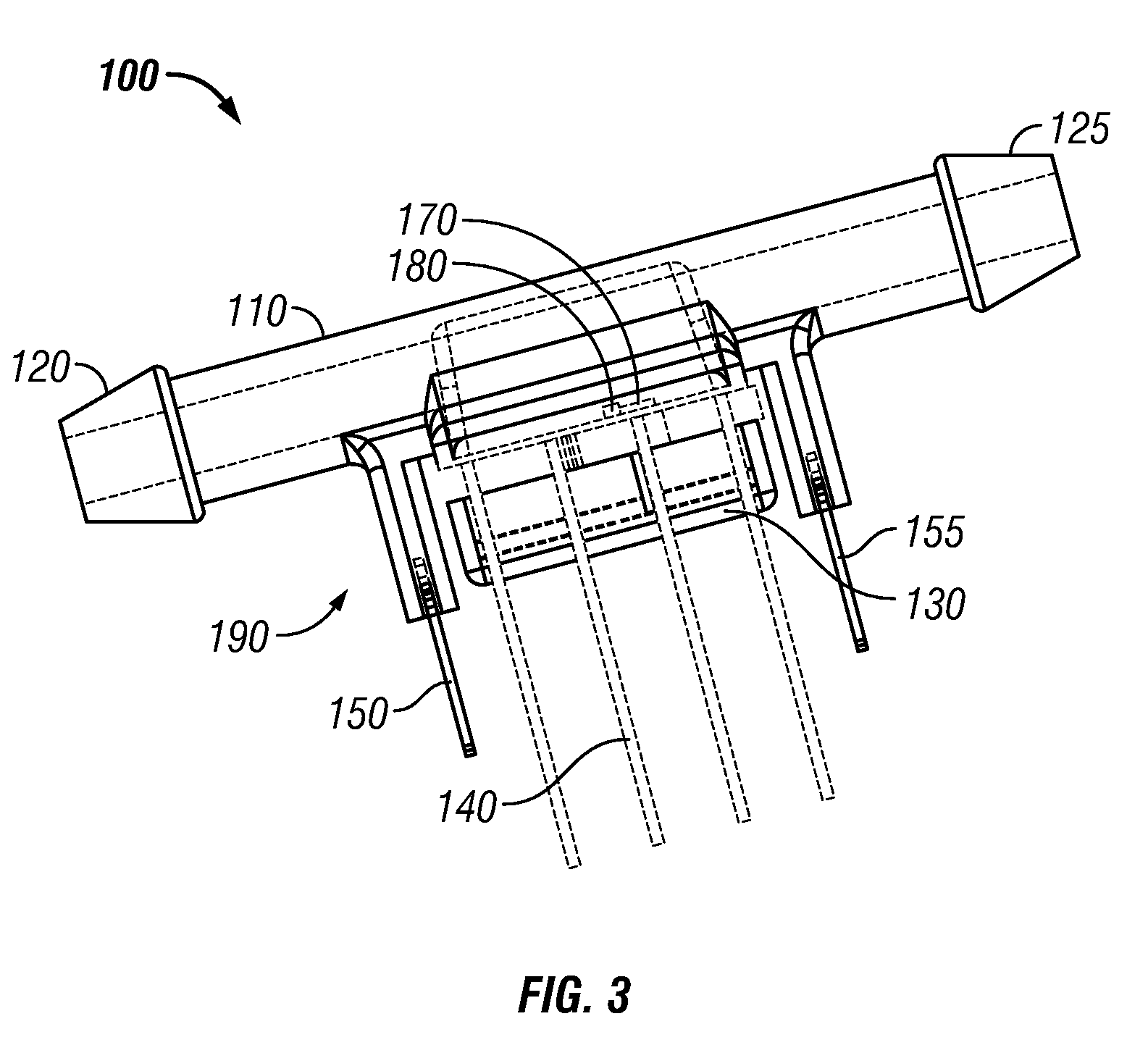

[0024]FIG. 1 illustrates a perspective view of a flow-through pressure sensor apparatus 100 utilizing surface mount technology (SMT), which can be implemented in accordance with a preferred embodiment. The apparatus 100 generally includes a housing 190 and a flow tube 110 having an inlet port 120 and an outlet port 125. A pressure sense die 180 and a programmable compensation integrated circuit 170 can be located on a substrate 130 and packaged inside the surface mount technology package housing 190, as shown in FIG. 3. The material of the substrate 130 can be configured from material such as, for example, ceramic, alumina, or a fiberglass PC board material, such as FR4 or FR5, although other ceramics may be utilized to implement substrate 130. Ceramic materials having a lower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com