Liquid holding container and liquid consuming apparatus

a technology of liquid consuming apparatus and liquid holding container, which is applied in printing and other directions, can solve the problems of liquid not being able to be held, liquid cannot be refilled, and it is difficult for air to intermix with the moving liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]Hereinafter, an embodiment of the invention will be described according to the following order in order to clarify the content of the invention.[0026]Apparatus Configuration[0027]Method for Filling Ink Tank with Ink[0028]Variations

[0029]First Variation

[0030]Second Variation

[0031]Third Variation

Apparatus Configuration

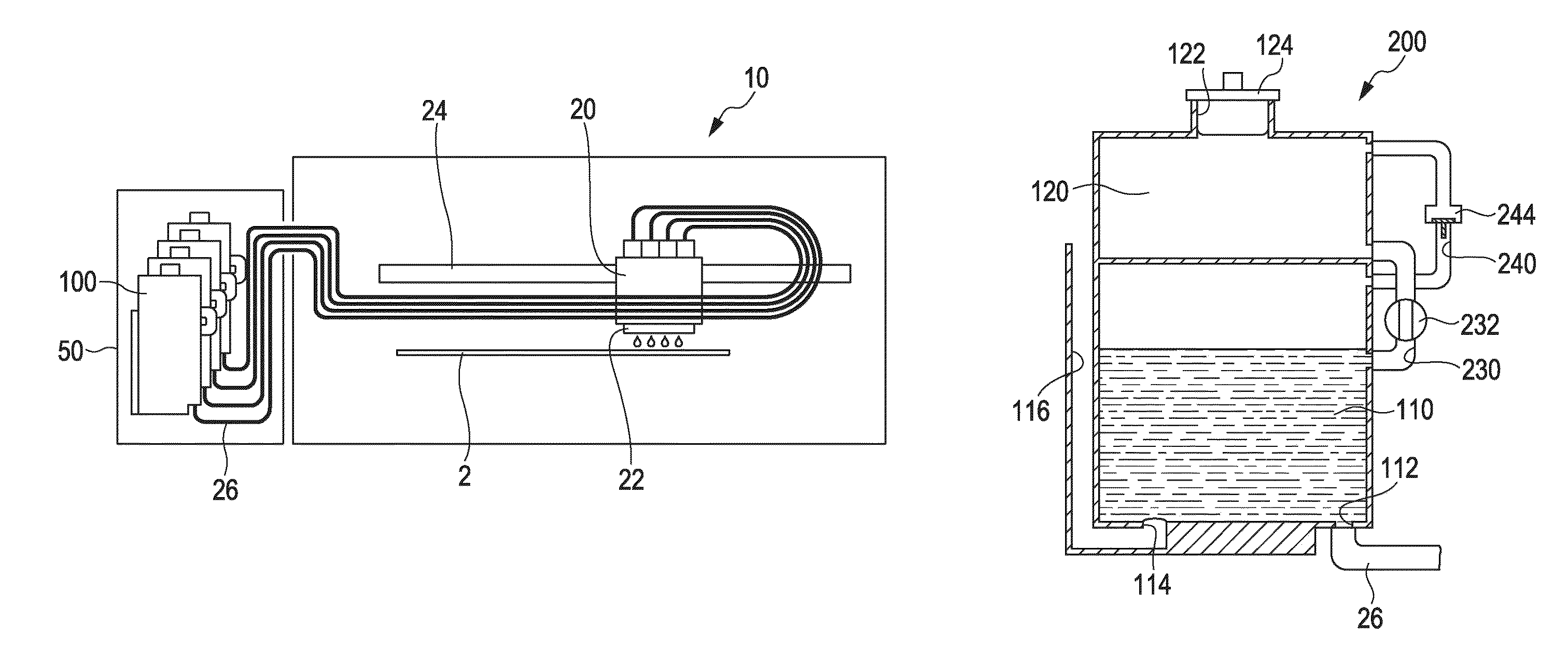

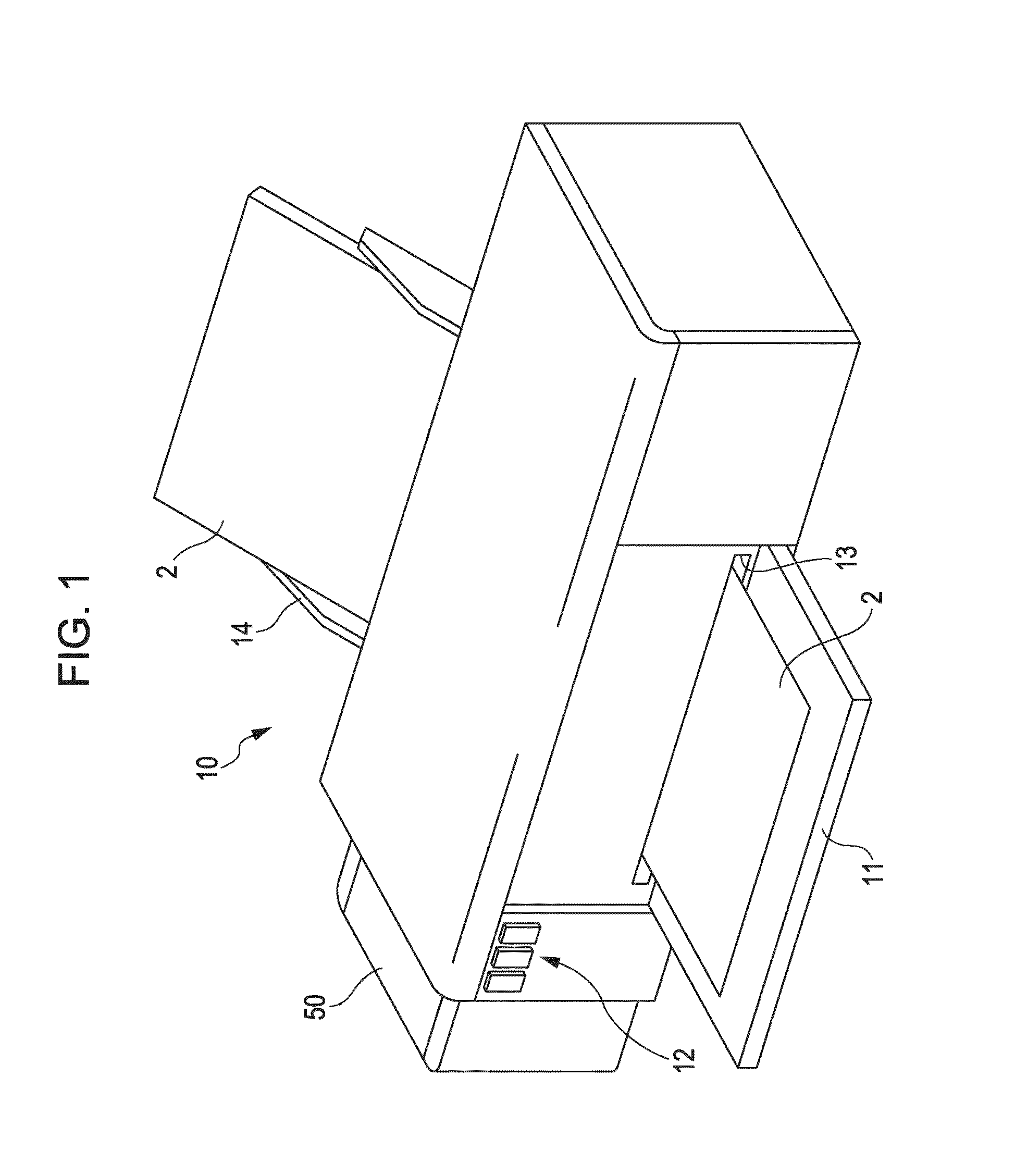

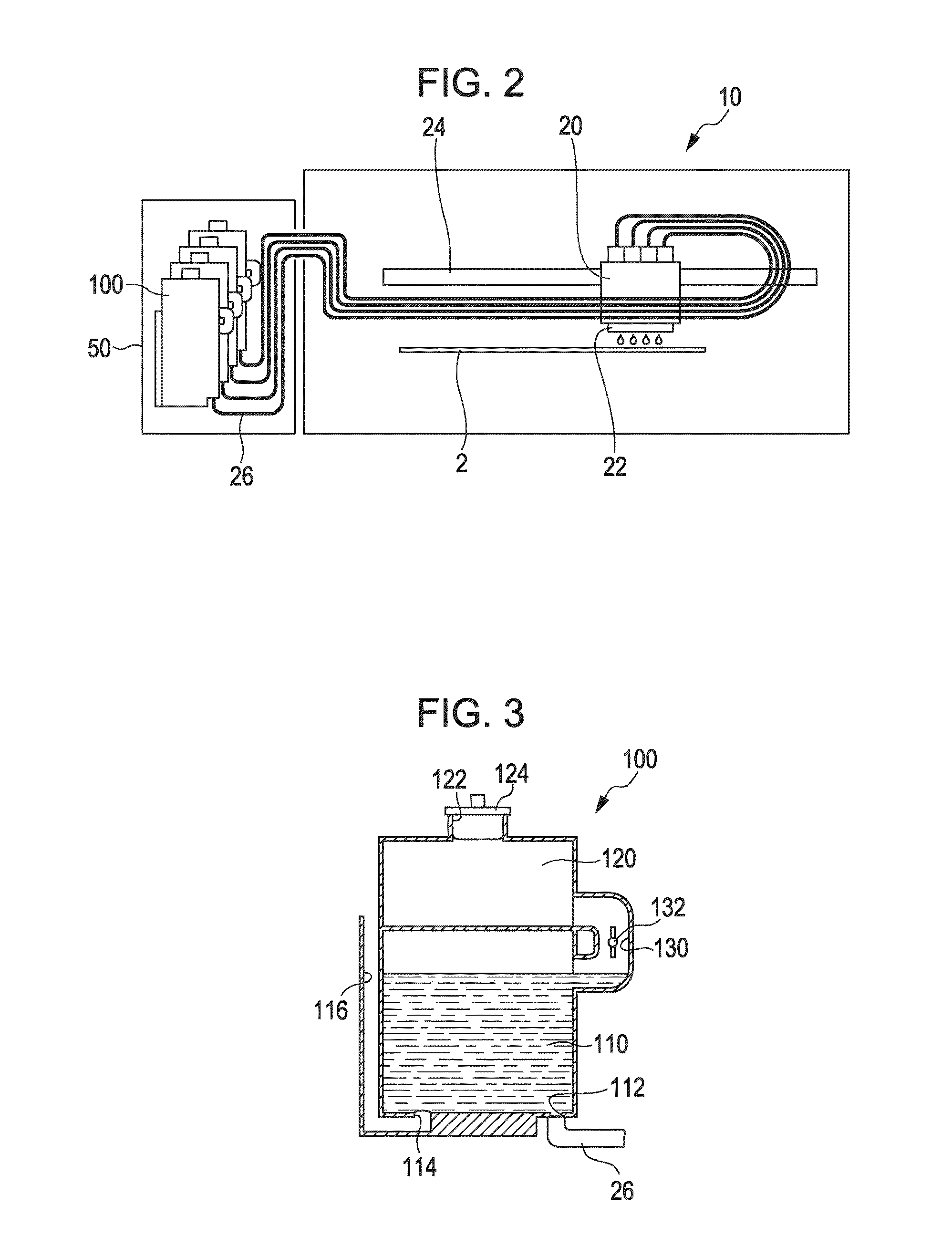

[0032]FIG. 1 is a schematic diagram illustrating the general configuration of a liquid consuming apparatus according to this embodiment, using what is known as an ink jet printer as an example. An ink jet printer 10 has an approximately box-shaped outer shape; a front cover 11 is provided in essentially the center of the front surface of the printer, and a plurality of operation buttons 12 are provided to the left thereof. The front cover 11 is axially supported on its lower end, and a long, thin paper discharge port 13 from which print paper 2 is discharged is exposed when the upper end of the front cover 11 is tilted forward. In addition, a paper supply tray 14 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com