Temperature-stable LC oscillators and methods of oscillation at temperature null phase

a technology of inductor capacitor and oscillator, which is applied in the direction of oscillator, pulse automatic control, pulse technique, etc., can solve the problems of increasing the complexity of electronic systems, limiting the size and cost reduction of electronic systems, and the need for extra circuitry and techniques to decrease and/or compensate for frequency shifts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]Summary

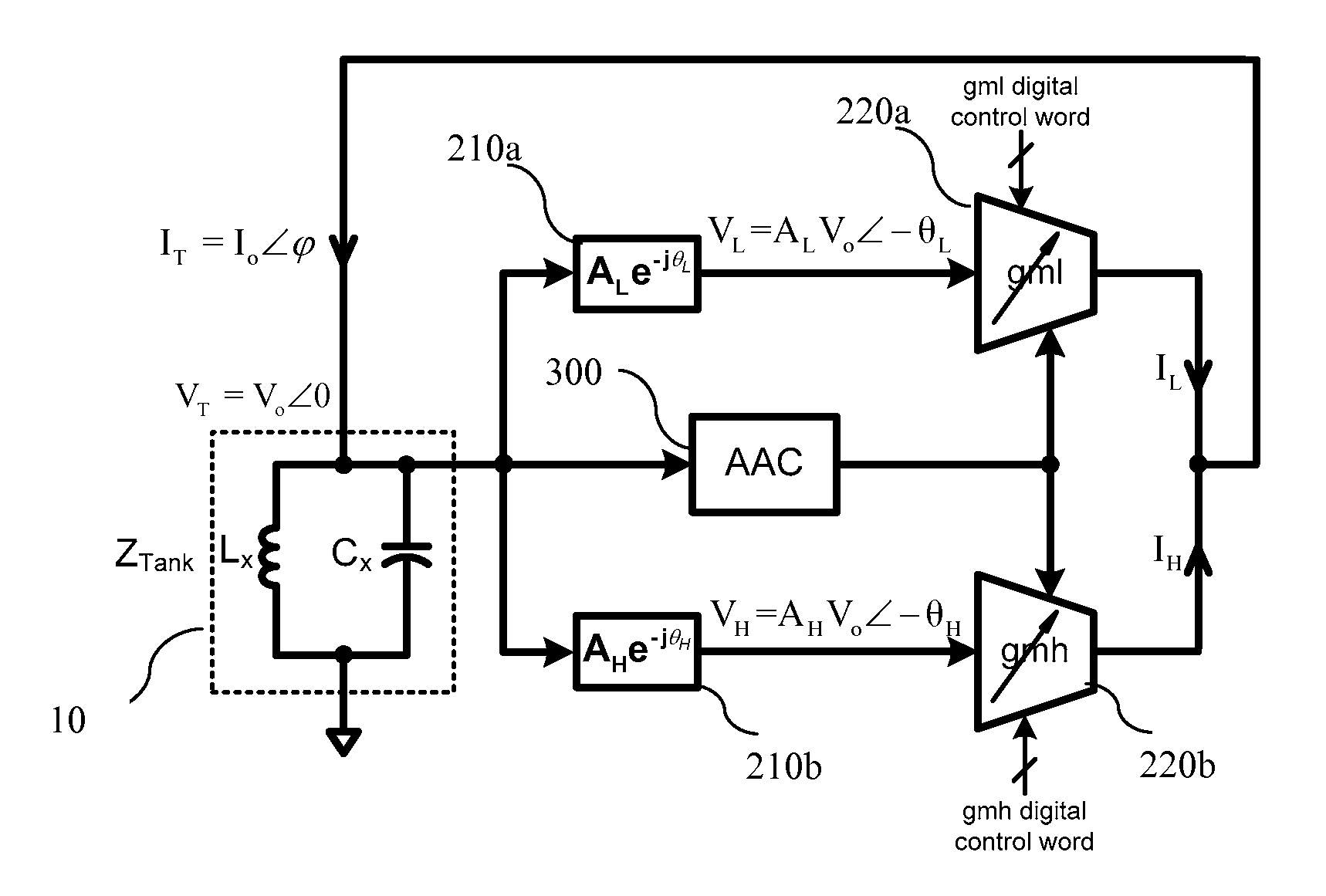

[0019]The present invention provides a substantially temperature-independent LC-based oscillator. The oscillator includes an LC oscillator tank and frequency stabilizer circuitry coupled to the LC oscillator tank to cause the LC oscillator tank to operate at a temperature null phase generating a tank oscillation at a phase substantially equal to a temperature null phase. The temperature null phase is a phase of the LC oscillator tank at which variations in frequency of an output oscillation of the oscillator with temperature changes are reduced or minimized.

[0020]For example, the feedback loop may split the output voltage of the LC tank into two voltages having different phases, where each voltage is independently transformed into a current through programmable transconductors. The two currents may be combined to form a resultant current which is then applied to the LC tank. The phase of the resultant current is adjusted such that the LC tank operates at an impedance co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com