Mud motor

a technology of motors and mud, applied in the direction of machines/engines, mechanical devices, couplings, etc., can solve the problems of seal leakage, premature failure of bearing assemblies, pressure drop between upper and lower seals of bearing assemblies, etc., and achieve the effect of facilitating the rotation of the passageway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

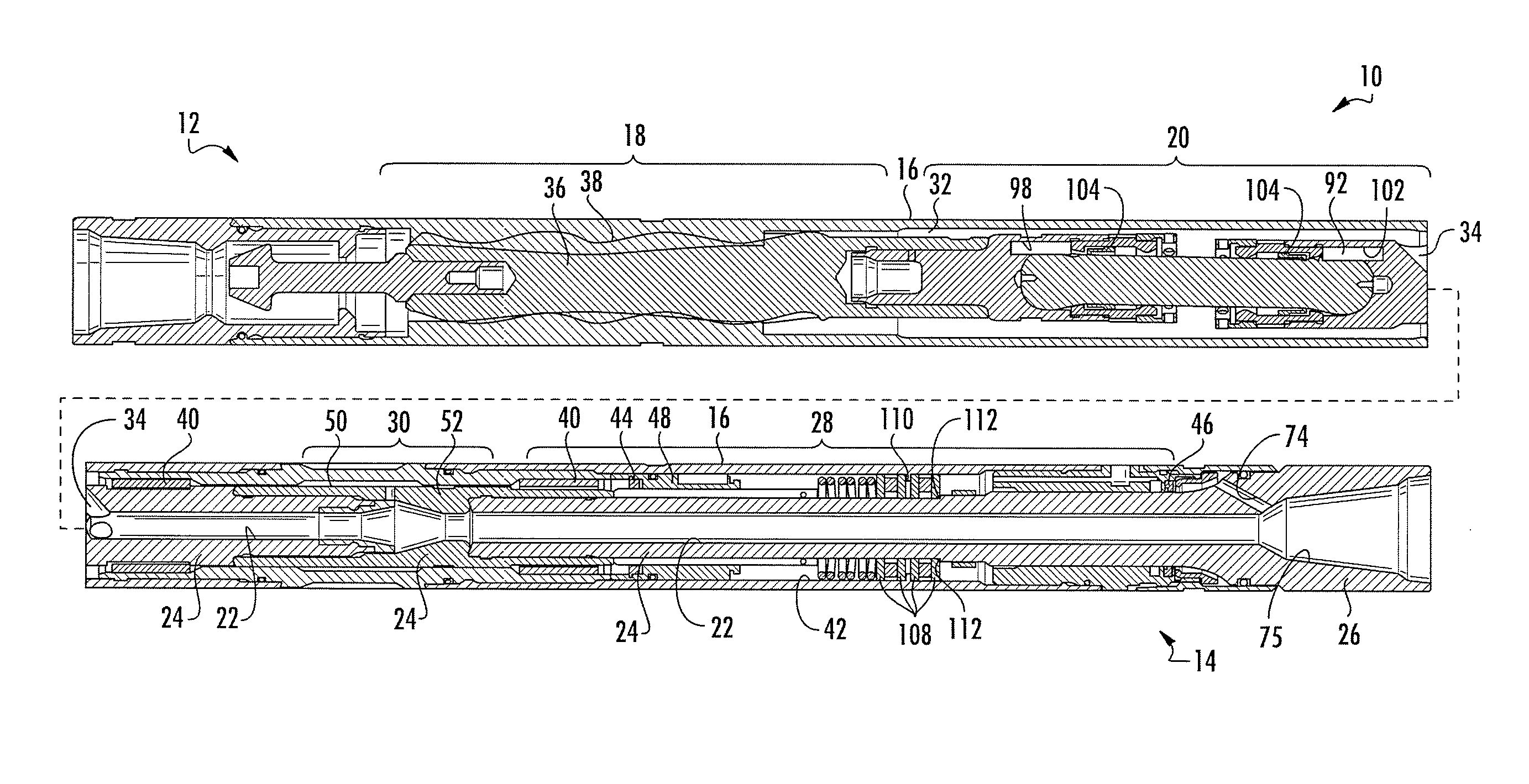

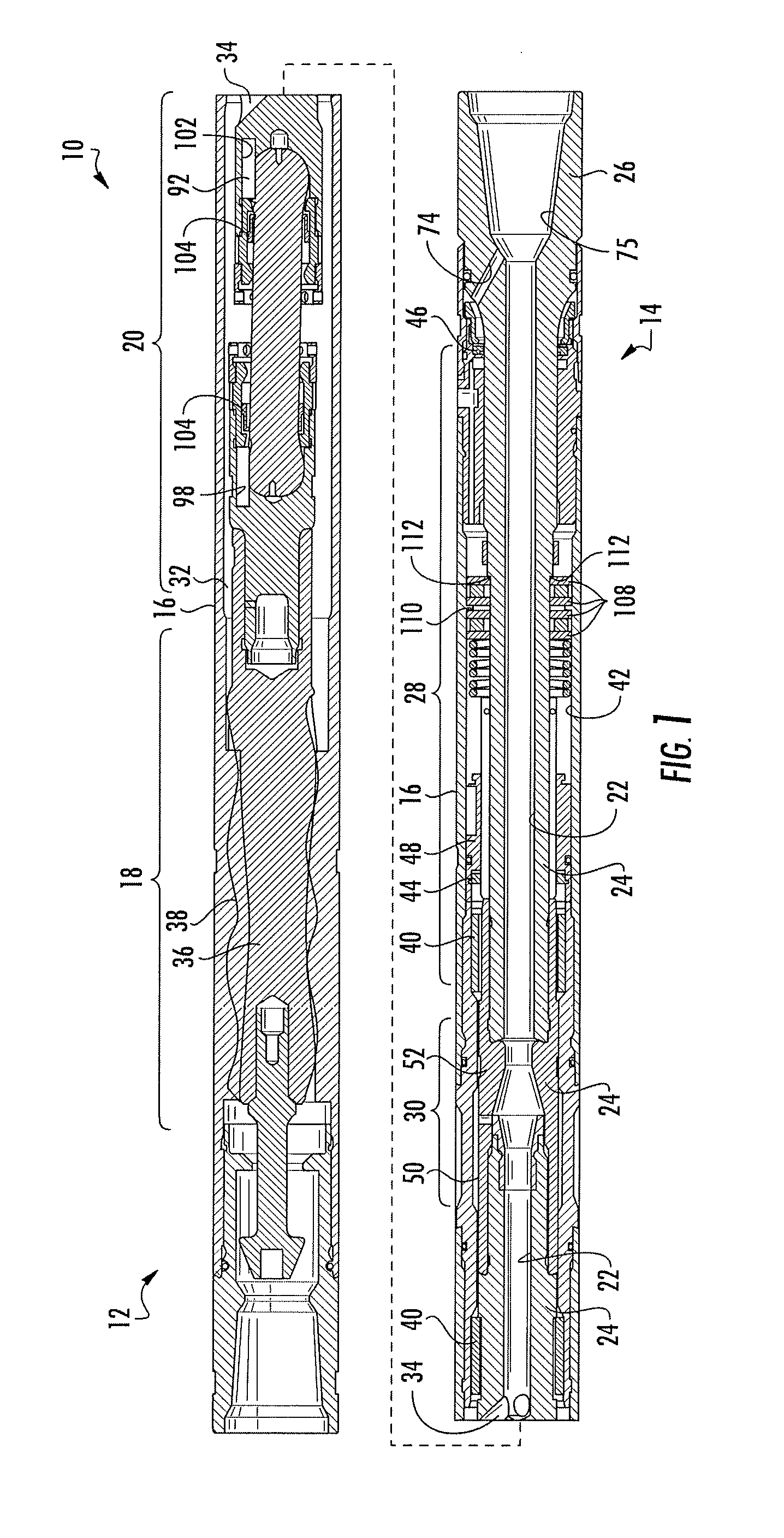

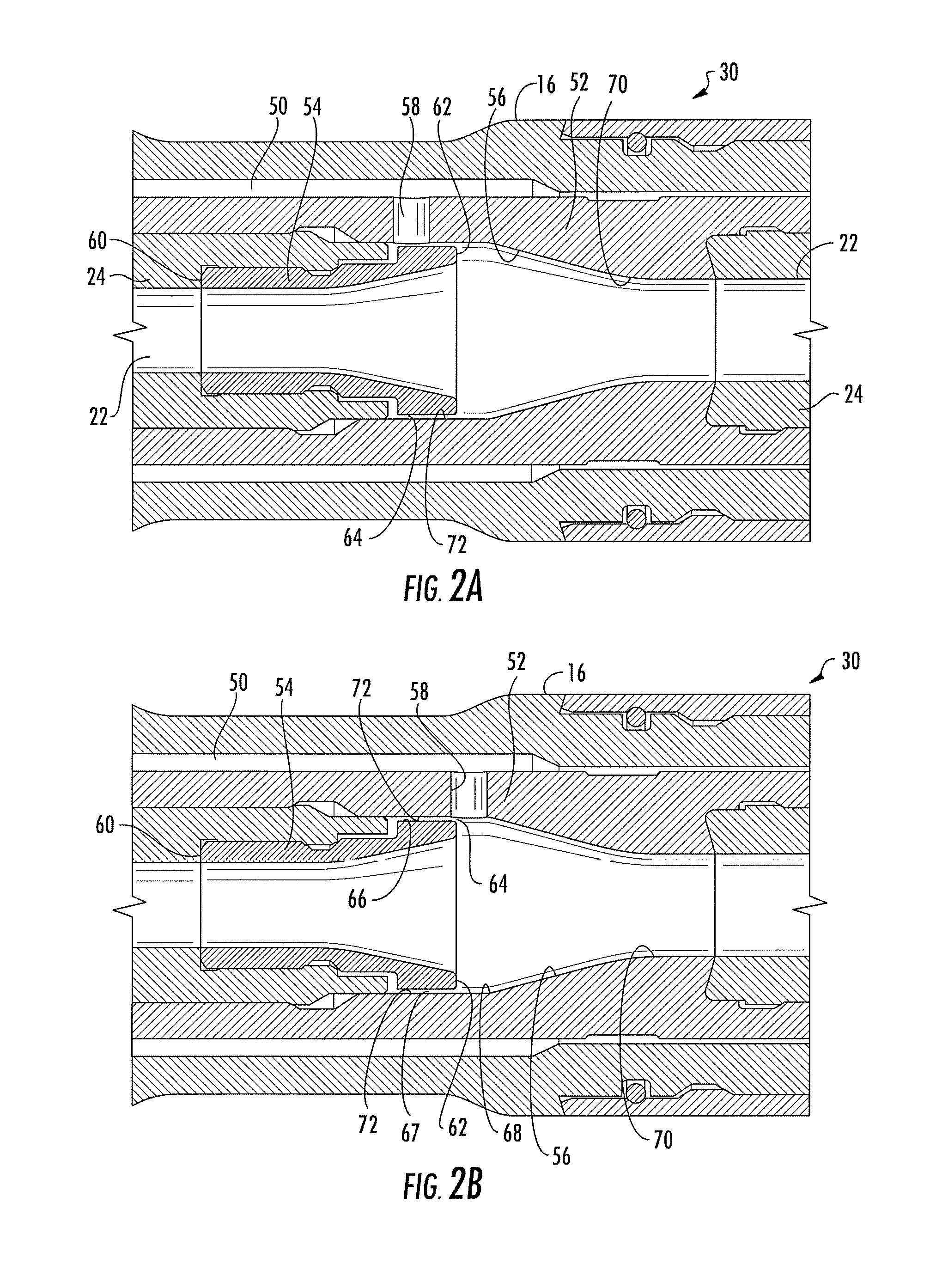

[0020]The present disclosure relates to a mud motor 10 used in downhole oil and gas operations that substantially reduces a pressure drop (or pressure differential) across the portions of the mud motor 10 caused by the friction of fluid (e.g., mud, drilling fluid, drilling mud, etc.) flowing therethrough. The present disclosure is also directed to a method of using this mud motor while maintaining a substantially balanced pressure drop across various portions of the mud motor. Shown in FIG. 1, the mud motor 10 includes an upper portion 12, a lower portion 14 and a housing 16 for encapsulating various parts of the mud motor 10.

[0021]The upper portion 12 includes a power section 18 for driving / forcing the fluid through the mud motor 10 and rotating the various parts of the mud motor 10 encapsulated in the housing 16 and a drive shaft assembly 20 for transferring the rotation produced by the power section 18 to other components disposed in the lower portion 14 of the mud motor 10.

[0022...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com