Systems and methods for detecting materials in food products

a food product and food technology, applied in the field of systems and methods for detecting materials in food products, can solve the problems of serious consequences, food that is improperly labeled as “organic” has been found in grocery stores, and can easily be mixed with non-organic food, so as to achieve the effect of affecting the detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

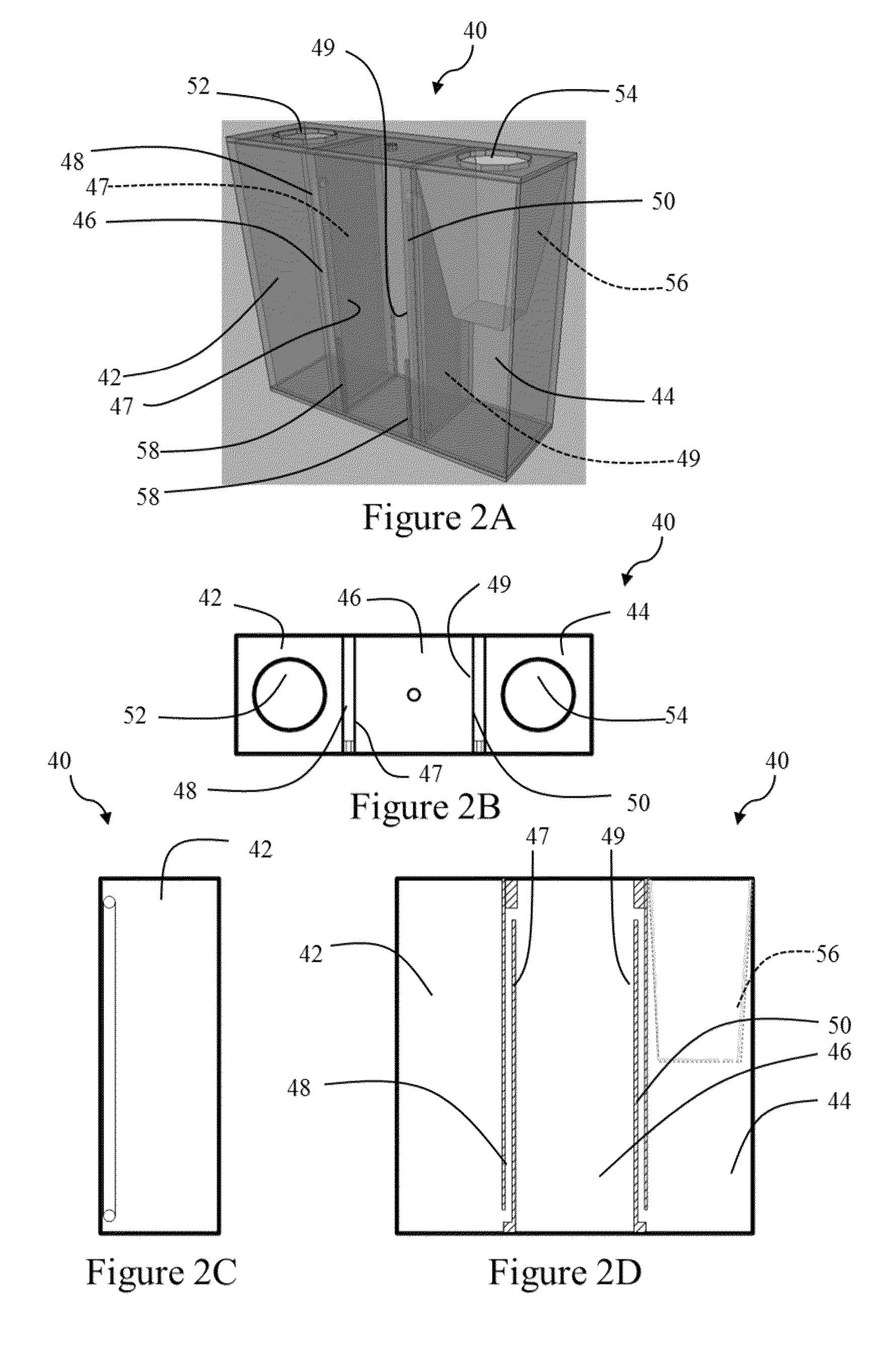

[0042]The following specific examples are provided for illustrative purposes of how to use the device, cartridge and method of this technology.

[0043]I. Solutions are Transferred from the Outer Compartments of a Sample Cartridge to the Middle Compartment by a Pneumatic Filling System.

[0044]Pure water (representing a solvent) was transferred into a first outer (solvent) compartment of a sample cartridge. Water containing blue dye (representing a sample solution) was transferred into a second outer (sample) compartment of the sample cartridge. The outer compartments were hermetically sealed with seals and an injector was inserted through each seal without disrupting the hermetic seal. The insertion of the injectors did not compromise the hermetic seal. The injectors were connected to pump, which supplied pneumatic pressure. The following steps were then performed:[0045]1. transfer 920 μL of the water containing dye from the second outer (sample) compartment to the middle compartment at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flow rate | aaaaa | aaaaa |

| pneumatic pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap