[0005]The injection device according to the present invention and the internal combustion engine according to the present invention according to the coordinate claims have, in relation to the existing art, the advantage that the cold start capacity at lower temperatures is improved and exhaust gas emissions are reduced. This effect is achieved through a combination of the heating of the fuel before the injection, using the heating device, and the injection of the fuel via two separate injection valves. The use of two separate injection valves, the first and the second injection valve, promotes a homogenous and stable combustion of the injected fuel precisely in the start and warm-up phase, because each injection valve has to inject only a reduced throughput quantity of fuel.

[0006]This results in a lower spray density, i.e. the characteristic drop size, in particular the Sauter mean diameter, of the atomized fuel is advantageously reduced and the portion of evaporated fuel in the intake manifold is increased, achieving a faster and more stable complete combustion of the fuel mixture in the combustion chamber. The better complete combustion of the fuel mixture in the combustion chamber further enables a later ignition angle with the same uneven running, causing an increased temperature in the combustion chamber or in the exhaust tract. The cold start characteristics are thus already improved solely through the use of the two separate injection valves. Through a combination with the heating device, this effect can be increased severalfold, so that advantageously significantly increased cold start characteristics can be achieved even with the use of alternative fuels such as (bio)ethanol, compressed natural gas (CNG), or liquefied natural gas (LNG). In contrast to the existing art, the injection device according to the present invention therefore allows operation with alternative fuels without the occurrence of problems during cold starting resulting from the use of such fuels. The injection device according to the present invention may be provided or fashioned for the injection of ethanol, gasoline-ethanol mixtures, compressed natural gas (CNG), or liquefied natural gas (LNG). Due to having fewer impurities, ethanol or natural gas generally burn cleaner than gasoline and therefore produce less exhaust gas, so that the injection device according to the present invention permits a more environmentally friendly operation with reduced exhaust gas emissions compared to the existing art. The internal combustion engine according to the present invention may include an Otto engine having intake manifold injection for a motor vehicle, which may be an automobile. The internal combustion engine may have more than one cylinder.

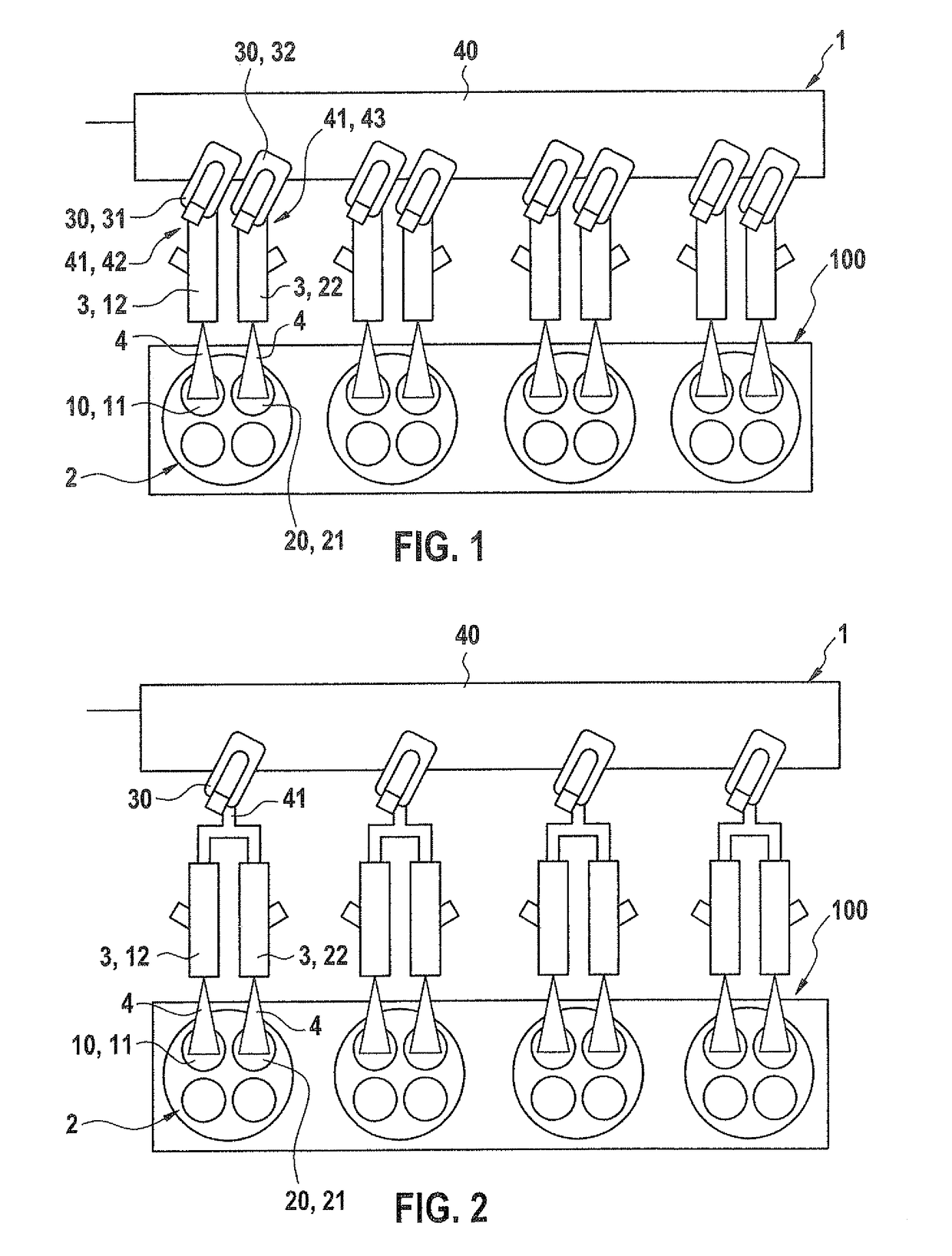

[0009]According to a specific embodiment, it is provided that the first and second injection valve are capable of being controlled independently of one another, and / or the first and second injection valve are differently dimensioned in such a way that different quantities of fuel can be injected by the first and the second injection valve. Advantageously, the use of the two separate injection valves reduces the minimum quantity for each valve that can still be injected by the injection valves with a high degree of precision. At the same time, the on times for each of the injection valves are in this way made longer for the injection of the same quantity of fuel, so that a longer switch-on pulse is required for the injection of a small quantity of fuel. In this way, the precision of the injection process is significantly increased, and the danger that one of the injection valves will operate in a nonlinear range during injection of a very small quantity of fuel is removed. This effect is reinforced by the different dimensioning of the injection valves.

[0010]Advantageously, with the smaller-dimensioned injection valve a very small quantity of fuel can still be injected with a high degree of precision, while with the larger-dimensioned injection valve large quantities of fuel can nonetheless be injected in a short time. The metering range of the injection valve system is therefore significantly increased by the different dimensioning and by a separate controlling. Through a precise dosing of the injected fuel quantity, in addition a better and error-free complete combustion is achieved, in particular given rapid changes of load (in which the throttle valve for example opens abruptly, so that there is the danger of the air-fuel mixture becoming leaner), ensuring a reliable cold start phase and lower emission rates. Alternatively, the first and second injection valve may always be controlled in parallel.

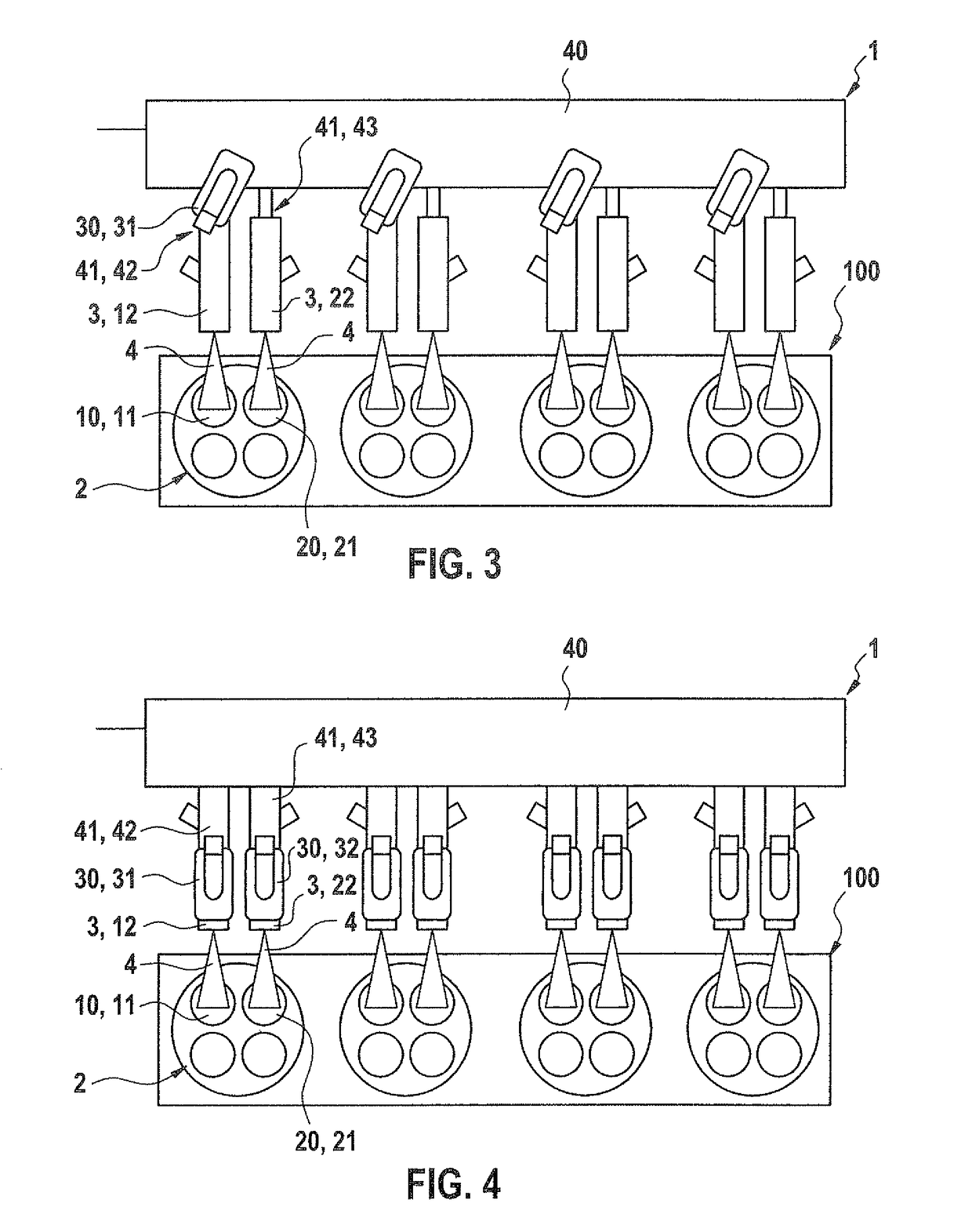

[0012]Alternatively, both the first heating unit may be integrated in the first injection valve and the second heating unit is integrated in the second injection valve. In this way, the cold start characteristic can be further increased, because both the fuel injected by the first injection valve and the fuel injected by the second injection valve are heated by the heating device. The first and second heating unit are in particular capable of being controlled separately from one another, and are activated in the cold start and warm-up phase in particular only given low outside temperatures.

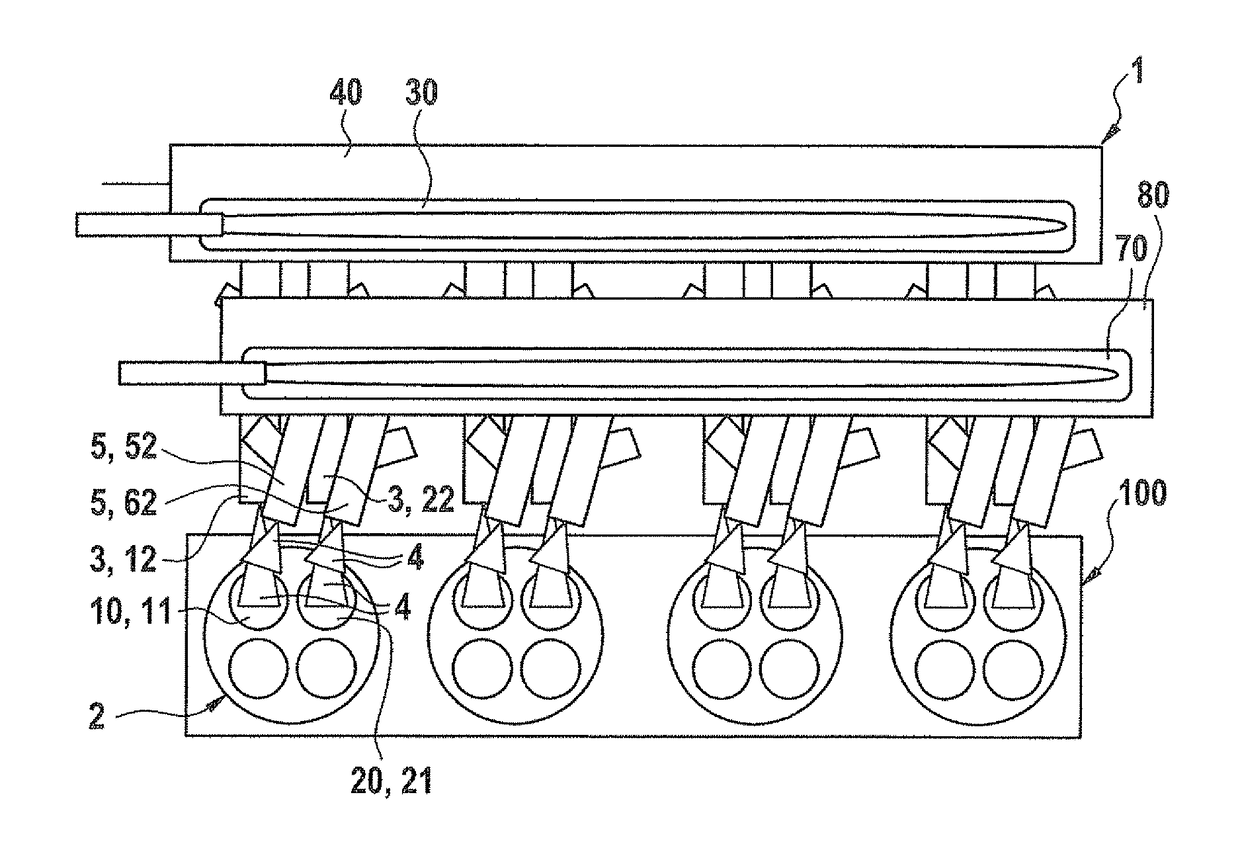

[0016]According to a specific embodiment, it is provided that the injection device has a further injection valve system that has a third injection valve for injecting fuel in the direction of the first inlet opening and a separate fourth injection valve for injecting fuel in the direction of the second inlet opening, the third and the fourth injection valve may be capable of being controlled independently of one another, and / or the third and fourth injection valve may be differently dimensioned such that different quantities of fuel can be injected by the third and the fourth injection valve. The use of the additional injection valve system advantageously results in a higher heat input into the fuel per cylinder, so that the cold start characteristics are further improved. In addition, a better dynamic characteristic is achieved when there are transient changes in quantity, as well as a better engine throughput after the start phase, in the post-start and warm-up phase. The third and fourth injection valve may be provided or fashioned for the injection of gasoline, ethanol, gasoline-ethanol mixtures, compressed natural gas (CNG), or liquefied natural gas (LNG. The first and second injection valve system may each inject fuel having essentially the same composition.

Login to View More

Login to View More  Login to View More

Login to View More